×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

Genuine Mazda Protege Clutch Master Cylinder

- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Clutch Master Cylinders found

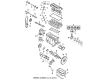

Mazda Protege Master Cylinder Part Number: GE4T-41-990C

$141.55 MSRP: $188.77You Save: $47.22 (26%)Ships in 1-2 Business DaysMazda Protege Master Cylinder Part Number: BR70-41-990A

$182.70 MSRP: $243.64You Save: $60.94 (26%)Ships in 1-2 Business DaysMazda Protege Master Cylinder Part Number: BC6D-41-990B

$152.26 MSRP: $199.86You Save: $47.60 (24%)Ships in 1-2 Business Days

Mazda Protege Clutch Master Cylinder

The Mazda Protege Clutch Master Cylinder is a device that is applied to translate your foot pressure on the clutch pedal into hydraulic force, so that the gears can change every time. The piston and clutch fluid are sealed up in its small metal body and therefore, when the driver steps on the pedal, the piston will move forward, squash the fluid, and then push it through a line to the slave cylinder that pulls the clutch away from the spinning flywheel. This straight hydraulic connection ensures that pedal effort remains light and travel remains predictable, which is essential when driving in the city with heavy stop-and-go traffic as well as when making quick shifts during highway driving for typical Mazda commuters. Throughout all the years of production of a Protege, Mazda maintained a simple single piston design without testing different bore sizes or cable systems, allowing all the years to feel the same and troubleshooting to be very easy. Red flags like spongy pedal, dripping fluid around the firewall, grinding when selecting a gear, or the inability of the pedal to rebound are indications that there is either air or a leak in the Clutch Master Cylinder and this needs to be handled before it can extend to the slave or transmission. Regular fluid replacement is necessary to maintain the lubrication of surfaces of Clutch Master Cylinder seals, and since the component is identical to the brake system in fluid characteristics, moisture-free brake fluid is essential. Failure will lead to the possibility of the pedal falling on the floor and a gear change being virtually impossible, but with the fluid maintained at the top, the lines properly tight, and the rubber gasket intact, it is easy to get the durable Mazda component to go well beyond 100,000 miles.

Looking for Clutch Master Cylinder with proven quality? Choose OEM Clutch Master Cylinder. Mazda designs and builds them to strict factory specs. Every piece goes through rigorous quality checks. You'll get parts that fit right and work like new. Shop our huge inventory of OEM Mazda Protege parts. Enjoy the highly competitive prices online. Our site is your one-stop shop. Each genuine Protege part includes a manufacturer's warranty. Buy with confidence. Our return policy is simple and hassle-free. In a rush? Choose expedited delivery at checkout. You'll love the streamlined experience from search to checkout to receiving your order.

Mazda Protege Clutch Master Cylinder Parts and Q&A

- Q: What steps should you take before rebuilding or replacing the Clutch Master Cylinder on Mazda Protege?A:Prior to commencing this process, check with local part stores and dealer service departments in regards to the purchase of a rebuild kit or a new master cylinder because the availability and pricing of the required parts may determine which option to choose between rebuilding or replacing the cylinder. In case of a decision of rebuilding the cylinder, examine the bore. Unplug the negative cable and then the positive cable in the battery with the right activation code of any anti-theft system before disconnection. Lift battery hold-down clamp, battery cover and battery itself. Take out the bolt fastening the diagnosis connector and put it aside. At the clutch master cylinder, detach clamp and reservoir fluid hose, and inserted the hose to store fluid eliminating the loss of fluid and rags would be required. Use a flare-nut wrench to disconnect the hydraulic line at the clutch master cylinder. Under the dash, loosen the nuts holding the master cylinder to the firewall and then delicately take out the master cylinder so as not to spill the fluid. Incidentally, turn the master cylinder to drain the trapped fluid and hold the cylinder in a vise with the piston end facing upwards. Using a Phillips screwdriver, push the piston downwards and with snap-ring pliers, loosen the snap-ring, being careful not to scratch the push rod contact surface. Use a block of wood to tap the master cylinder and force out the piston, spacer, primary cup and spring. Take off the seal of the piston and examine the bore deeply, looking in scratches or ridges; when the surface is not smooth the master cylinder has to be changed. In case of rebuilding, assemble the new parts of the rebuild kit, washing all parts that can be used with brake cleaner or clean brake fluid, and not with petroleum based solvents. Install a new seal with seal lips turned out of the push rod end onto the piston, lubricate the bore, spring, primary cup, spacer and piston using new brake fluid and slowly insert them into the cylinder bore. Return the cylinder to the vise, press the piston down, and add a new snap-ring. Apply a dollop of grease on the end of the push rod, slide the master cylnder on the push rod against the firewall, and for the mounting nuts, use your fingers to loosely screw them in place. Attach the hydraulic line to the master cylinder making sure not to cross thread the fitting and then screw the mounting nut and hydraulic line fitting in place. Install the reservoir hose back to the master cylinder, install the diagnosis connector and battery, refill the clutch/brake fluid reservoir with brake fluid which meets the requirements of DOT 3 and bleed the clutch system. Lastly, test the free play and height of a clutch pedal.

Related Mazda Protege Parts

Browse by Year

2003 Clutch Master Cylinder 2002 Clutch Master Cylinder 2001 Clutch Master Cylinder 2000 Clutch Master Cylinder 1999 Clutch Master Cylinder 1998 Clutch Master Cylinder 1997 Clutch Master Cylinder 1996 Clutch Master Cylinder 1995 Clutch Master Cylinder 1994 Clutch Master Cylinder 1993 Clutch Master Cylinder 1992 Clutch Master Cylinder 1991 Clutch Master Cylinder 1990 Clutch Master Cylinder