×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

Genuine Mazda MX-5 Miata Brake Hose

Brake Line- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

8 Brake Hoses found

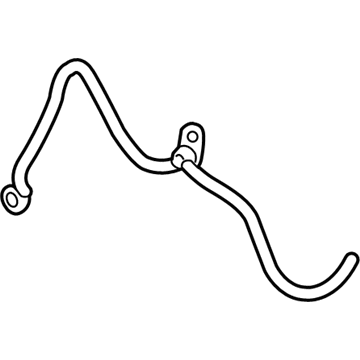

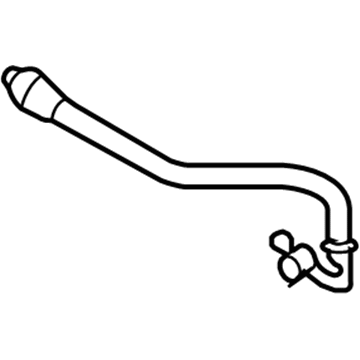

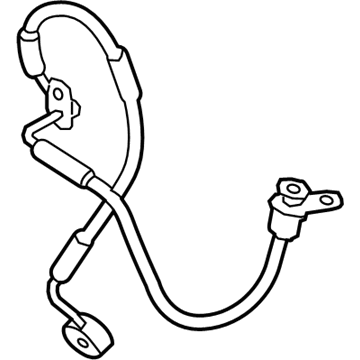

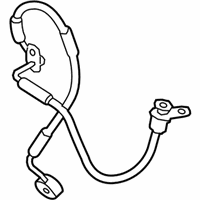

Mazda MX-5 Miata Flex Hose Part Number: N243-43-810A

$30.08 MSRP: $40.10You Save: $10.02 (25%)Ships in 1-2 Business DaysMazda MX-5 Miata Flex Hose Part Number: NA5F-43-980A

$76.48 MSRP: $101.99You Save: $25.51 (26%)Ships in 1-2 Business DaysMazda MX-5 Miata Flex Hose Part Number: NA5F-43-990A

$76.80 MSRP: $102.42You Save: $25.62 (26%)Ships in 1-2 Business DaysMazda MX-5 Miata Flex Hose Part Number: N243-43-980A

$78.01 MSRP: $104.04You Save: $26.03 (26%)Ships in 1-2 Business DaysMazda MX-5 Miata Flex Hose Part Number: N243-43-990A

$88.55 MSRP: $118.09You Save: $29.54 (26%)Ships in 1-2 Business DaysMazda MX-5 Miata Flex Hose Part Number: NF47-43-810B

$102.54 MSRP: $136.75You Save: $34.21 (26%)Ships in 1-2 Business DaysMazda MX-5 Miata Flex Hose Part Number: NF47-43-990A

$132.21 MSRP: $176.32You Save: $44.11 (26%)Ships in 1-2 Business DaysMazda MX-5 Miata Flex Hose Part Number: NF47-43-980B

$134.13 MSRP: $178.87You Save: $44.74 (26%)Ships in 1-2 Business Days

Mazda MX-5 Miata Brake Hose

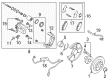

Looking for Brake Hose with proven quality? Choose OEM Brake Hose. Mazda designs and builds them to strict factory specs. Every piece goes through rigorous quality checks. You'll get parts that fit right and work like new. Shop our huge inventory of OEM Mazda MX-5 Miata parts. Enjoy the highly competitive prices online. Our site is your one-stop shop. Each genuine MX-5 Miata part includes a manufacturer's warranty. Buy with confidence. Our return policy is simple and hassle-free. In a rush? Choose expedited delivery at checkout. You'll love the streamlined experience from search to checkout to receiving your order.

Mazda MX-5 Miata Brake Hose Parts and Q&A

- Q: How often should you inspect the Brake Hose connecting the steel brake lines to the brake assemblies, and what steps are involved in replacing it on Mazda MX-5 Miata?A:Approximately every six months, when the vehicle is on jackstands and the rubber hoses that contain the steel brake lines are attached to the front and rear assemblies, check them to ensure no cracks, chafing or leaks, and blisters or other damages are present since they are very important elements of the brake system. Check well with a light and a mirror and change any hose which has signs of wear. Describing how to replace the front brake hose, it is necessary to loosen the lug nuts of the wheel, raise the car, and take out the wheel. Unscrew the brake line fitting on the hose by an opening-end wrench to prevent rounding off the corners, and keep the hose fitting by an open-end wrench. Use the pliers to take the U-clip out of the female covering in the bracket and thread the hose through the bracket. Removal of the banjo fitting bolt at the caliper end and hose separation at the caliper end with replacement of the two copper sealing washers is necessary during installation. Installation of the new hose To install the new hose feed the caliper fitting end through any bracket required and then attach it to the caliper using the banjo bolt and the new copper sealing washers, and ensure that the locating lug is seated in the caliper hole and then tighten the bolt to required torque. Install the U-clip in the strut bracket by pushing by the hose support and make sure that the hose is not twisted. Install the hose in the frame bracket by routing the hose into the frame bracket, connecting the brake line fitting by hand, attaching the U-clip and firmly attaching the fitting. Once the caliper has been bled, assemble the wheel and lug nuts, and lower the vehicle and attach the lug nuts to the correct torque. The rear brake hose has two line of rigid metal, each on the body and the suspension, fitted at the end with threaded fittings and U-clips. There are right brake lines to be used and when replacing brake lines do not use copper tubing, and buy steel brake lines in a dealer or auto parts store. Ready-to-go brake lines with flared tube ends and attached fittings are offered and unless pre-bent brake lines are offered then strip the faulty line away and buy a straight section of brake line that is similar in length to the original and bend it to look as the original would appear with correct tubing bending equipment. Make sure that the new line is firmly held in the bracket(s) and is out of the way of moving or hot parts. Once the master cylinder has been installed, check the level of fluid in the cylinder and add fluid where required and then bleed the brake system and test the brakes thoroughly before driving the vehicle into a traffic jam.