×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

Genuine Mazda MX-6 Brake Hose

Brake Line- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Brake Hoses found

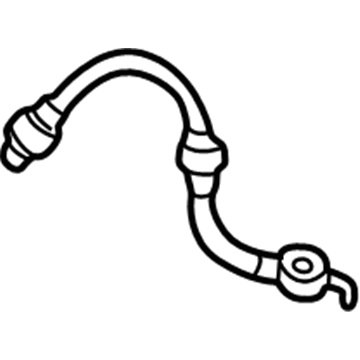

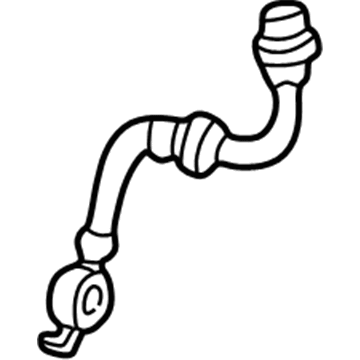

Mazda MX-6 Hose Part Number: GA2A-43-810

$29.98 MSRP: $39.97You Save: $9.99 (25%)Ships in 1-2 Business DaysMazda MX-6 Hose Part Number: GA2E-43-980

$51.75 MSRP: $69.01You Save: $17.26 (26%)Ships in 1-2 Business DaysMazda MX-6 Hose Part Number: B455-43-980B

$56.04 MSRP: $74.73You Save: $18.69 (26%)Ships in 1-2 Business DaysMazda MX-6 Hose Part Number: G030-43-980B

$48.88 MSRP: $65.17You Save: $16.29 (25%)Ships in 1-2 Business DaysMazda MX-6 Brake Hose Part Number: G031-43-810C

Mazda MX-6 Brake Hose

Looking for Brake Hose with proven quality? Choose OEM Brake Hose. Mazda designs and builds them to strict factory specs. Every piece goes through rigorous quality checks. You'll get parts that fit right and work like new. Shop our huge inventory of OEM Mazda MX-6 parts. Enjoy the highly competitive prices online. Our site is your one-stop shop. Each genuine MX-6 part includes a manufacturer's warranty. Buy with confidence. Our return policy is simple and hassle-free. In a rush? Choose expedited delivery at checkout. You'll love the streamlined experience from search to checkout to receiving your order.

Mazda MX-6 Brake Hose Parts and Q&A

- Q: How often should you inspect the Brake Hose connecting the steel brake lines to the brake assemblies on Mazda MX-6?A:The flexible hoses joining the steel brake lines to the front and rear brake assemblies are very important parts of the brake system, and should be inspected about every six months, with the vehicle raised and firmly on jackstands, to look at them and note any cracks, chafing, leaks, blisters, etc. A mirror and light will help bring a complete search. In case of any problems identified, change the brake hose of the front, and use a back-up wrench to disconnect this hose with the brake line pipe, loosen the flare nut and remove the clip before attaching the new hose by installing the clip and tightening the flare nut. When fitting, make sure all threads in the bolt are clean, and that the hose is not kinked and is clear of any contact with any parts of the suspension, by turning the wheels completely to the left and right. In case of the rear brake hose, unscrew the hose at both sides with the help of a back-up wrench, taking care not to bend the bracket or steel lines, and take off any clips and unbolt the hose retaining clip. Fit the new hose, do not twist, fit the female ends in the frame brackets and fit the clips. Attach the steel line fittings to the female fittings with a back-up wrench, and make sure that the frame bracket is not loose and re-torque them. Add master cylinder reservoir and bleed. In case of a steel line replacement, the steel should be replaced with a type of copper tubing which is prone to fatigue cracking and corrosion. Auto parts shops will have a wide range of prefabricated brake line of varying lengths; otherwise, get recommended steel tubing and fittings, measure old line length and cut new line with an additional 1/2-inch to flare. Install fittings on the cut tubing and flare the ends with an ISO flaring tool, and bend the tubing using a tubing bender to the shape of the old line. Tube flaring and bending may be done in local auto parts stores in case of necessity. At least 3/4-inch space should be maintained between the brake line and any moving components during installation.