×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

Genuine Mazda MX-6 Brake Master Cylinder

- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

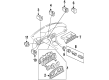

3 Brake Master Cylinders found

Mazda MX-6 Master Cylinder Part Number: GA2E-43-40ZR-00

Mazda MX-6 Master Cylinder Part Number: GA2H-43-40ZR-00

Mazda MX-6 Master Cylinder Part Number: GJ21-43-400R-0E

Mazda MX-6 Brake Master Cylinder

Looking for Brake Master Cylinder with proven quality? Choose OEM Brake Master Cylinder. Mazda designs and builds them to strict factory specs. Every piece goes through rigorous quality checks. You'll get parts that fit right and work like new. Shop our huge inventory of OEM Mazda MX-6 parts. Enjoy the highly competitive prices online. Our site is your one-stop shop. Each genuine MX-6 part includes a manufacturer's warranty. Buy with confidence. Our return policy is simple and hassle-free. In a rush? Choose expedited delivery at checkout. You'll love the streamlined experience from search to checkout to receiving your order.

Mazda MX-6 Brake Master Cylinder Parts and Q&A

- Q: What steps should be taken before starting the Brake Master Cylinder overhaul procedure on Mazda MX-6?A:Before beginning the process, buy a master cylinder overhaul kit that consists of all the required parts in the form of replacement parts including rubber parts such as seals, which are essential in controlling fluids. Make sure that these components are fixed properly and in the right position without getting in touch with grease or solvents of mineral nature. Guard against spillage of brake fluid in front of fender and cowling of the vehicle. Disengage the brake line connections, and put a rag or newspapers under the master cylinder so that it can absorb any fluid draining out. Disconnect the fluid level sensor connector, loosen the 2 mounting nuts, and then lift master cylinder out of the vehicle. By gently rocking the master cylinder, drain all the remaining fluid in the reservoir. Install the master cylinder vertically and have the front end of the cylinder face down, press the primary piston, and take off the snap ring. Take out the main piston and put in another one of the overhaul kit. Depress the secondary piston using a wooden dowel destroying the O-ring and screw, and then tap the master cylinder using a block of wood to remove the secondary piston. Deactivate the spring on the front side of the secondary piston, and the rear spreader, the cylinder cup seal, the two shims of the valve, and two seals on the back of the piston. Unscrew the reservoir bushings, cap, and float and clean the master cylinder, examining it, and replacing it in case of corrosion or damage. Inspect the reservoir of cracks and deteriorated bushings, and change the parts when necessary. When assembling them, lubricate every part with clean brake fluid. Fit the valve shim, seals and O-ring to the secondary piston lubricating the two pistons. Install the set screw, the spring depressed slightly and the secondary piston assembly into the bore. Slide the primary piston in so that the spring is facing forward, push it down a bit then attach the snap ring. Lubricate reservoir bushings, place the body of a master cylinder on the reservoir and install the reservoir level float and baffle assembly. Once the master cylinder has been removed, bleed the entire hydraulic system and this can be done faster by filling the master cylinder with fluid and priming prior to installation. Pour in oil at the reservoir, squeeze the piston in, close the ports of brake lines, then release the piston until no more fluid is spurted out. Install the master cylinder using the power brake reservoir studs, the brake line flare nuts, are finger tightened and the retaining nuts are installed, tighten the flare nuts and the level sensor is once again connected. Lastly, bleed the brakes at wheel bleed valves.