×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

Genuine Mazda RX-7 Starter

Starter Ignition- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Starters found

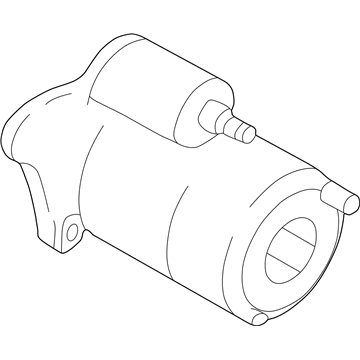

Mazda RX-7 Starter Part Number: N327-18-400R-00

Mazda RX-7 Starter Part Number: N3A1-18-400R-00

Mazda RX-7 Starter

The Mazda RX-7 Starter delivers cranking power to the rotary engine ignition within seconds, transforming the electricity in the battery into wheel-spinning power in the eccentric shaft. The unit is contained in a small case, and heavy-gauge current is fed to it by a solenoid attached to it, and then an internal armature rotates on field windings or permanent magnets, whose rotation in turn activates a small pinion to engage with the flywheel until combustion takes over. During the manufacturing of the model, Mazda employed two key methods. The early series cars applied a direct-drive type where the armature is linked to the pinion and no gears are involved, providing a simple construction but requiring greater current. Subsequent generations applied a gear-reduction design, where the armature is driven by a group of planetary or spur gears in such a way that it is able to rotate faster, and the pinion rotates more slowly yet with higher torque, enabling easier cold starts and a reduction in package weight. The two types also have an overrunning clutch that automatically disengages once the Starter completes its task before the revs can damage it. Its signal is given to the solenoid only after the ignition switch, the relay, and the neutral or clutch safety switch have verified that all is safe, preventing accidental cranking when the vehicle is in gear. In all the years that Mazda made sure that the device was electric instead of being pneumatic or hydraulic, the weight was kept down and maintenance was easy. The reliable performance that this Starter offers is important in the eyes of the owners, since without it the unique Mazda RX-7 would not even step out of the driveway.

Looking for Starter with proven quality? Choose OEM Starter. Mazda designs and builds them to strict factory specs. Every piece goes through rigorous quality checks. You'll get parts that fit right and work like new. Shop our huge inventory of OEM Mazda RX-7 parts. Enjoy the highly competitive prices online. Our site is your one-stop shop. Each genuine RX-7 part includes a manufacturer's warranty. Buy with confidence. Our return policy is simple and hassle-free. In a rush? Choose expedited delivery at checkout. You'll love the streamlined experience from search to checkout to receiving your order.

Mazda RX-7 Starter Parts and Q&A

- Q: How can a starter be disassembled or overhauled, and what steps should be followed during the process on Mazda RX-7?A:One can disassemble the starter and change it to a new or reused unit or can overhaul it and replace the battery, prices, and parts availability will be deciding. To start with, you need to remove the field strap and the solenoid off the starter body then take the spring, plunger, and the washer out of the nose of the solenoid. Disassemble the back cover by unscrewing the through-bolts and screws in the rear of the brushes holder and remove the insulator and washers in the rear end of the armature shaft. Fit out the yoke and the brush holder assembly, lifting out the armature, driving lever and over-running clutch assembly. The armature assembly should be clamped in a vise with wood blocks in order to prevent damage and then the stop ring at the end of the shaft should be removed, perhaps by pushing the pinion stop collar aside. The stop ring should be removed and the stop collar and over-running clutch slid off. When continuity is not found between the armature coil core and either of the commutators, examine the continuity with an ohmmeter, and replace the armature where continuity is found. Check continuity between the commutators, and substitute armature in the event of lack of continuity. Clean a dirty/worn commutator using emery paper and cut the mica between commutators to a depth. The field terminal is in the yoke, which should be tested to continuity with the terminal, and the field coil and yoke assembly replaced, should it be present. It should also be ensured that there is continuity between the field termini and all the field coil brush and in the event of a non-occurrence, replacement of the field coil and the yoke assembly is necessary. Check continuity between individual brush holders and the brush holder frame, replacement of the assembly in case continuity occurs. Check the brushes and discard them when so worn out, to more than one-third of the original length, with a little hammer or pliers, scraping off the old brush, and solder it to the new one. Check the clearance between the armature shaft and the front and rear bushings and change the bushings in case the clearance is greater. Install starter with a reversed order taking two clearance checks: verify the end play of armature shaft end adjustable with a thrust washer, and clearance between the solenoid and stop collar when solenoid is engaged also adjustable by putting a washer between the solenoid body and driving housing.