×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

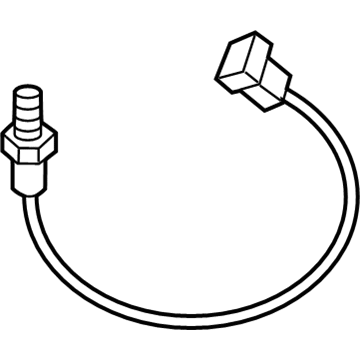

Genuine Mazda Tribute Oxygen Sensor

Oxygen O2 Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

14 Oxygen Sensors found

Mazda Tribute Oxygen Sensor Part Number: AJ03-18-861D

$93.39 MSRP: $124.54You Save: $31.15 (26%)Ships in 1-2 Business DaysMazda Tribute Oxygen Sensor Part Number: ZZC0-18-860

$61.64 MSRP: $82.20You Save: $20.56 (26%)Mazda Tribute Oxygen Sensor Part Number: ZZC4-18-861

$44.78 MSRP: $59.71You Save: $14.93 (25%)Mazda Tribute Oxygen Sensor Part Number: ZZCB-18-860

$70.70 MSRP: $94.29You Save: $23.59 (26%)Mazda Tribute Upper Oxygen Sensor Part Number: ZZDM-18-861

$108.04 MSRP: $144.08You Save: $36.04 (26%)Mazda Tribute Oxygen Sensor Part Number: 1F20-18-860A

Mazda Tribute Oxygen Sensor Part Number: AJ04-18-861B

Mazda Tribute Oxygen Sensor Part Number: AJ05-18-861B

Mazda Tribute Oxygen Sensor Part Number: AJ06-18-861D

Mazda Tribute Oxygen Sensor Part Number: ZZC3-18-860

Mazda Tribute Oxygen Sensor Part Number: ZZC3-18-861

Mazda Tribute Oxygen Sensor Part Number: ZZD1-18-860

Mazda Tribute Oxygen Sensor Part Number: ZZDA-18-861

Mazda Tribute Front Oxygen Sensor Part Number: ZZDL-18-861

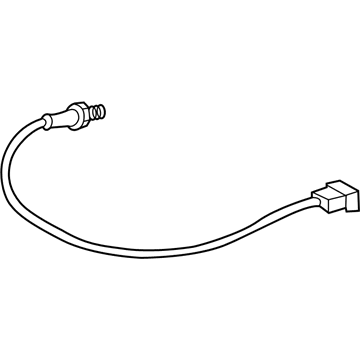

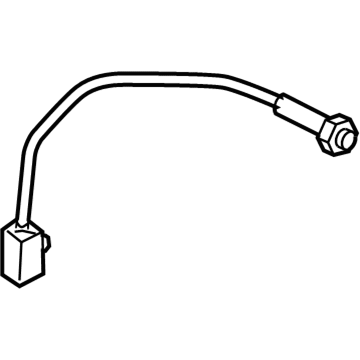

Mazda Tribute Oxygen Sensor

Looking for Oxygen Sensor with proven quality? Choose OEM Oxygen Sensor. Mazda designs and builds them to strict factory specs. Every piece goes through rigorous quality checks. You'll get parts that fit right and work like new. Shop our huge inventory of OEM Mazda Tribute parts. Enjoy the highly competitive prices online. Our site is your one-stop shop. Each genuine Tribute part includes a manufacturer's warranty. Buy with confidence. Our return policy is simple and hassle-free. In a rush? Choose expedited delivery at checkout. You'll love the streamlined experience from search to checkout to receiving your order.

Mazda Tribute Oxygen Sensor Parts and Q&A

- Q: What is the function of an oxygen sensor in relation to the Powertrain Control Module and catalytic converter performance on Mazda Tribute?A:An oxygen sensor is a galvanic battery that produces a low voltage as a response to the amount of oxygen in exhaust gases and supplies necessary input to the feedback loop with the Powertrain Control Module (PCM) to keep the optimal air/ fuel ratio of 14.7: 1 to achieve optimum Catalytic Converter operation. Car models with On-Board Diagnostics II (OBD-II) have two oxygen sensors (pre- and post-catalytic) that measure the efficiency of the converter by measuring the concentration of oxygen in the exhaust gases. In four-cylinder models, there is normally one upstream and one downstream, Catalyst Monitor Sensor, whilst in V6 there are more than one upstream sensors and one downstream catalysts. All oxygen sensors are also heated in order to increase the time taken to warm them and any mishandling during service should be avoided when attaching the pigtail permanently and the electrical connector permanently and also to prevent any contaminant coming in contact with the sensor. When changing an oxygen sensor, one may recommend warming the engine to facilitate the removal, use of anti-seize compound on the thread, in case of reusing an old one, and proper installation and torque. Once the battery has been reconnected the PCM will need to relearn its idle and fuel trim strategy to achieve maximum performance.