×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

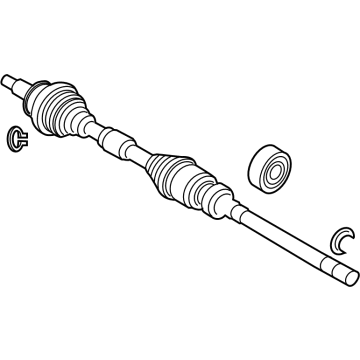

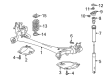

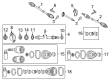

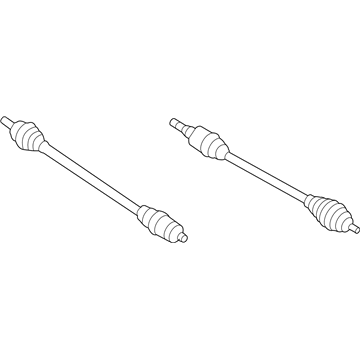

Genuine Mazda 3 Axle Shaft

Car Axle Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

77 Axle Shafts found

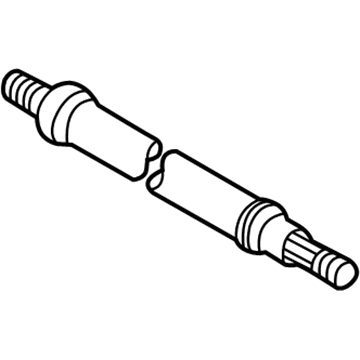

Mazda 3 Axle Part Number: BEET-28-B0XJ

$680.59 MSRP: $929.96You Save: $249.37 (27%)Ships in 1-2 Business DaysMazda 3 Axle Part Number: BFTD-28-B0XB

$691.50 MSRP: $944.86You Save: $253.36 (27%)Ships in 1-2 Business DaysMazda 3 Axle Assembly Part Number: FT21-25-50X

$710.41 MSRP: $970.69You Save: $260.28 (27%)Ships in 1-2 Business DaysMazda 3 Axle Part Number: BDTS-28-B0XF

$777.38 MSRP: $1062.22You Save: $284.84 (27%)Ships in 1-2 Business DaysMazda 3 Axle Part Number: BDWP-28-B0XG

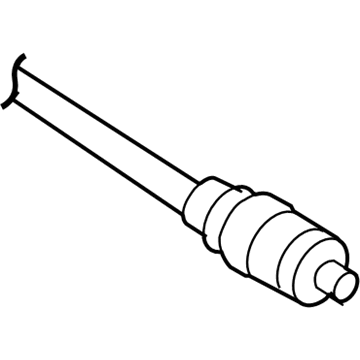

$867.47 MSRP: $1185.30You Save: $317.83 (27%)Ships in 1-2 Business DaysMazda 3 Shaft Part Number: GG38-25-730

$101.23 MSRP: $135.00You Save: $33.77 (26%)Ships in 1-2 Business DaysMazda 3 Shaft Part Number: GG47-25-700D

$192.71 MSRP: $257.00You Save: $64.29 (26%)Ships in 1-2 Business DaysMazda 3 Shaft Part Number: GG46-25-730

$179.34 MSRP: $239.17You Save: $59.83 (26%)Ships in 1-2 Business DaysMazda 3 Shaft Part Number: GG48-25-700C

$263.74 MSRP: $351.72You Save: $87.98 (26%)Ships in 1-2 Business DaysMazda 3 Axle Assembly Part Number: GG31-25-600C

$264.01 MSRP: $349.70You Save: $85.69 (25%)Ships in 1-2 Business DaysMazda 3 Shaft Part Number: GG38-25-700H

$288.23 MSRP: $384.37You Save: $96.14 (26%)Ships in 1-2 Business DaysMazda 3 Shaft Part Number: GG37-25-700B

$299.09 MSRP: $398.86You Save: $99.77 (26%)Ships in 1-2 Business DaysMazda 3 Shaft Part Number: GG51-25-700G

$316.11 MSRP: $421.57You Save: $105.46 (26%)Ships in 1-2 Business DaysMazda 3 Axle Assembly Part Number: FTC3-25-60X

$316.29 MSRP: $421.81You Save: $105.52 (26%)Ships in 1-2 Business DaysMazda 3 Axle Assembly Part Number: FTC4-25-60X

$316.29 MSRP: $421.81You Save: $105.52 (26%)Ships in 1-2 Business DaysMazda 3 Axle Assembly Part Number: GDC1-25-60X

$316.29 MSRP: $421.81You Save: $105.52 (26%)Ships in 1-2 Business DaysMazda 3 Shaft Part Number: GG25-25-700C

$319.09 MSRP: $425.53You Save: $106.44 (26%)Ships in 1-2 Business DaysMazda 3 Shaft Part Number: GG45-25-721

Mazda 3 Axle Assembly Part Number: GG26-25-600R-0K

Mazda 3 Axle Assembly Part Number: GG28-25-600R-0G

| Page 1 of 4 |Next >

1-20 of 77 Results

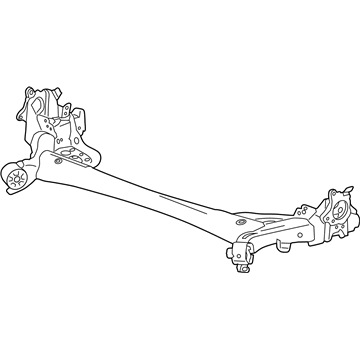

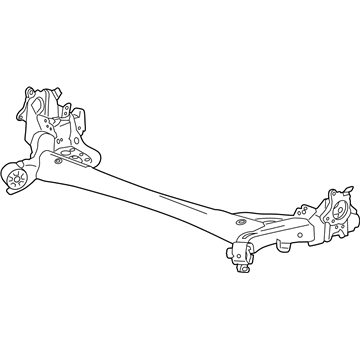

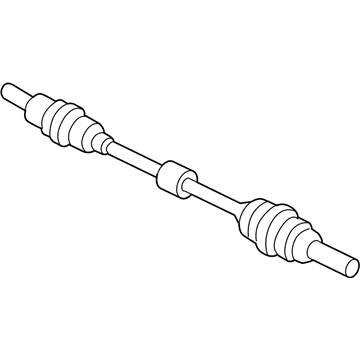

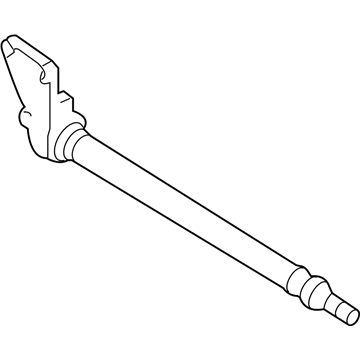

Mazda 3 Axle Shaft

Looking for Axle Shaft with proven quality? Choose OEM Axle Shaft. Mazda designs and builds them to strict factory specs. Every piece goes through rigorous quality checks. You'll get parts that fit right and work like new. Shop our huge inventory of OEM Mazda 3 parts. Enjoy the highly competitive prices online. Our site is your one-stop shop. Each genuine 3 part includes a manufacturer's warranty. Buy with confidence. Our return policy is simple and hassle-free. In a rush? Choose expedited delivery at checkout. You'll love the streamlined experience from search to checkout to receiving your order.

Mazda 3 Axle Shaft Parts and Q&A

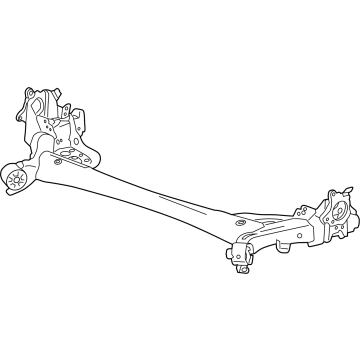

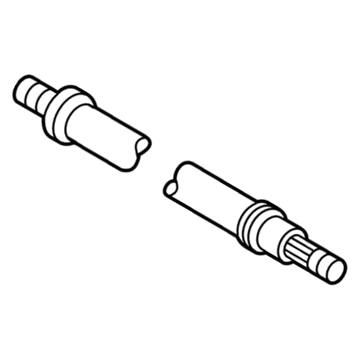

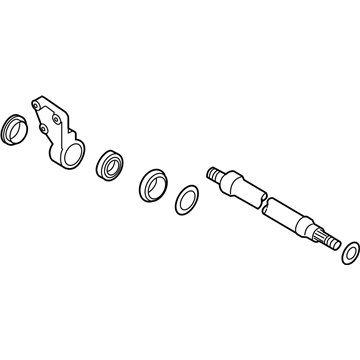

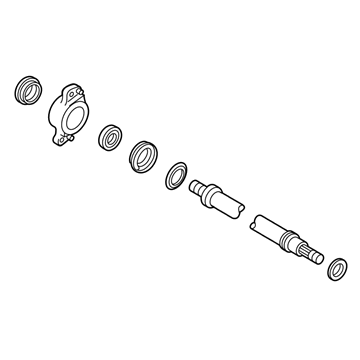

- Q: How to remove and install the axle shaft on Mazda 3?A:The axle shaft is next removed by first removing the wheel cover or hub cover followed by loosening the axle shaft/hub nut using a socket and a breaker bar. Unscrew the wheel lug nuts, lift the vehicle on jackstands and take away the wheel. The second step is to remove the pushpins holding the splash apron in the fenderwell, split the control arm and steering knuckle. Disconnect the brake hose tab to the steering knuckle, and remove the brake caliper mounting it so that it is out of tension on the flexible brake hose by removing the brake caliper and storing it out of the way. Take off and dispose the axle shaft/hub nut, place the wheel speed sensor aside and swing the knuckle/hub assembly out of the vehicle until the axle shaft is clear. In the event of the axle shaft splines becoming stuck, tap the inner end with a brass or plastic hammer, and hold the outer end with wire, so that the inner CV joint does not become strained. In the right axle shaft, pry the inner CV joint of the intermediate shaft and in the left axle shaft, pry it out of the transaxle, and do not damage the differential seal. Hold the CV joints and take off the axle shaft. Installation may require removing the old spring clip on the inner end of the axle shaft or an outer end of the intermediate shaft and replacing it with a new one and lubricating the seal on the diffusion or intermediate shaft. Install the axle shaft in place by holding the CV joints and making sure that the spring clip is with the opening side down. Insert the splined end of the inner CV joint into the side gear of the differential, or into the middle shaft making sure that the spring clip fits hold on. Lubricate the CV joint splines on the outside, yank out on the steering knuckle assembly, and install the stub axle in the hub. Disconnect the steering knuckle to the control arm, fit a new axle shaft/hub nut and screw it firmly without exceeding the torque specification until the vehicle is lowered. Install the wheel and lug nuts, then make sure that the axle shaft is properly seated in the transaxle or on the intermediate shaft, then lower the vehicle and firmly screw the lug nuts to the required torque, and then tighten the axle shaft/hub nut and place on the hub cover or wheel cap. In the case of the intermediate shaft, take off the right side wheel cover or hub cap, loosen the hub nut, lift up the vehicle and take the wheel out. Once the right axle shaft is removed, carefully take out the bearing support mounting bolts and then slide the intermediate shaft out of the transaxle, ensuring not to restrict the differential seal. Check the support bearing to ensure that it is smooth to operate, and in the event that a roughness is experienced, a replacement of the bearing is done at a qualified repair facility on the intermediate shaft. To install, grease the transaxle seal lips with grease, insert the intermediate shaft into the transaxle side gear and install the bearing support mounting fasteners making sure that the nut is tightened to the recommended torque. The rest of installation is the reverse process in the order of removal.

Related Mazda 3 Parts

Browse by Year

2024 Axle Shaft 2023 Axle Shaft 2022 Axle Shaft 2021 Axle Shaft 2020 Axle Shaft 2019 Axle Shaft 2018 Axle Shaft 2017 Axle Shaft 2016 Axle Shaft 2015 Axle Shaft 2014 Axle Shaft 2013 Axle Shaft 2012 Axle Shaft 2011 Axle Shaft 2010 Axle Shaft 2009 Axle Shaft 2008 Axle Shaft 2007 Axle Shaft 2006 Axle Shaft 2005 Axle Shaft 2004 Axle Shaft