×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

Genuine Mazda 626 Clutch Disc

Friction Disc- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Clutch Discs found

Mazda 626 Disc Part Number: FS04-16-460C

$98.63 MSRP: $131.53You Save: $32.90 (26%)Ships in 1-2 Business DaysMazda 626 Disc Part Number: KL07-16-460-9U

$100.35 MSRP: $133.83You Save: $33.48 (26%)Ships in 1-2 Business DaysMazda 626 Disc Part Number: F205-16-460C-9U

Mazda 626 Disc Part Number: KA22-16-460A-9U

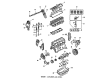

Mazda 626 Clutch Disc

Looking for Clutch Disc with proven quality? Choose OEM Clutch Disc. Mazda designs and builds them to strict factory specs. Every piece goes through rigorous quality checks. You'll get parts that fit right and work like new. Shop our huge inventory of OEM Mazda 626 parts. Enjoy the highly competitive prices online. Our site is your one-stop shop. Each genuine 626 part includes a manufacturer's warranty. Buy with confidence. Our return policy is simple and hassle-free. In a rush? Choose expedited delivery at checkout. You'll love the streamlined experience from search to checkout to receiving your order.

Mazda 626 Clutch Disc Parts and Q&A

- Q: How to remove and reinstall a transaxle with a Clutch Disc on Mazda 626?A:In order to take off the transaxle, initially make a mark on the relationship between the pressure plate and the flywheel so that it can be installed back in its place. Hold the clutch disc in place with alignment tool or screwdriver handle and loosen all the pressure plate retaining bolts in a criss-cross pattern to prevent warping. The pressure plate and clutch disc should be removed with great care and again, not on the lining surface. Disengage the release spring on the release fork hook, twist the release lever and release the release bearing then release fork bolt to raise the fork and release lever together. Wipe the housing of a clutch using a vacuum or cloth but not compressed air. Check the pressure plate, which needs to be replaced in case of its damage, wear, and overheating. Note flywheel contact, burnt, and wear, machine badly grooved flywheel. Check the lining of the clutch, looking out for contamination and wear, and changing the disc as necessary. Check the disc distortion and make sure it fits snugly in the input shaft, replacing it in case there are some concerns. examine the release bearing, as to wear and easiness of movement, and replace it in case of greater mileage of the vehicle. Check the mounting area of the clutch housing and associated parts of the components to the extent of necessary replacement and confirm that the pilot bearing in the crankshaft turns freely and replace when required. To fit, rub moly-base grease on the splines of the input shaft, clutch disc, and release bearing. Place the disc and maintain it using the alignment tool, put the pressure plate and align it with the already drawn marks. Insert the bolts in a criss-cross manner to the recommended torque, and insert release lever, fork, spring and bearing and leave the alignment tool out and insert the transaxle.

Related Mazda 626 Parts

Browse by Year

2002 Clutch Disc 2001 Clutch Disc 2000 Clutch Disc 1999 Clutch Disc 1998 Clutch Disc 1997 Clutch Disc 1996 Clutch Disc 1995 Clutch Disc 1994 Clutch Disc 1993 Clutch Disc 1992 Clutch Disc 1991 Clutch Disc 1990 Clutch Disc 1989 Clutch Disc 1988 Clutch Disc 1987 Clutch Disc 1986 Clutch Disc 1985 Clutch Disc 1984 Clutch Disc