×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

Genuine Mazda 626 Wheel Bearing

Hub Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Wheel Bearings found

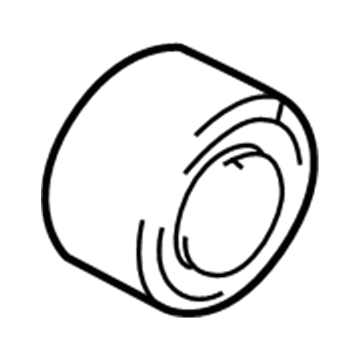

Mazda 626 Bearing Part Number: G569-25-155

$29.95 MSRP: $39.94You Save: $9.99 (26%)Ships in 1-2 Business DaysMazda 626 Wheel Bearing Part Number: GJ21-26-151-MV

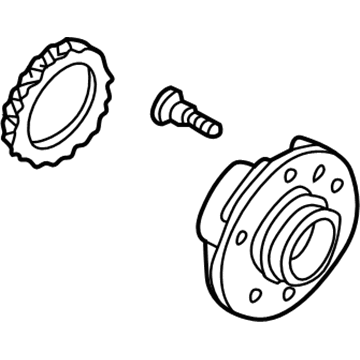

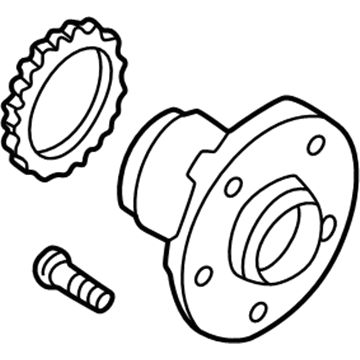

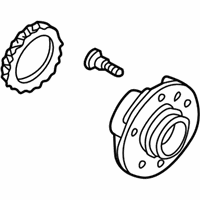

$56.66 MSRP: $75.56You Save: $18.90 (26%)Ships in 1-2 Business DaysMazda 626 Hub Assembly Part Number: GD7G-26-15X

$10.60 MSRP: $13.92You Save: $3.32 (24%)Ships in 1-2 Business DaysMazda 626 Wheel Bearing Part Number: B002-33-047

Mazda 626 Wheel Bearing Part Number: GA2A-33-047D-MV

Mazda 626 Bearing Part Number: H266-26-151-MV

Mazda 626 Wheel Bearing

The Mazda 626 Wheel Bearing allows each wheel to rotate with ease by reducing friction between the hub and the axle stub, which makes steering steady and the ride quiet. It is located in the wheel hub, where the Wheel Bearing's steel balls or tapered rollers slide within a hardened race to ensure that heat and drag are kept at a minimum, and the tires roll straight even at highway speeds. The series has had three primary bearing layouts over the years of production, which have been selected to fit the design of its drivetrain and safety technology. The sealed unit, which is an integral hub frequently containing the ABS sensor, is the common on later Mazda sedans and is replaced as a complete unit when worn out, which saves space and prevents the lubricant from being splashed by road conditions. Other front-driven models use a two-part construction which, although it is still assembled as a whole unit, has to be forced open at the steering knuckle during service, allowing easy access and providing the same compact sealed appearance when put back together. Earlier Mazda vehicles with non-driven rear axles can have opposed tapered roller sets, which can be separated and then freshly greased and preloaded carefully to last a long time. Regardless of style, all Wheel Bearings bear the weight of the vehicle, and at the same time, the hub is able to rotate with minimal vibration being felt, and neglecting rumbling or play may result in uneven tire wear as well as poor handling and wheel separation. Healthy Wheel Bearing on a routine check will assist any Mazda 626 to provide its drivers with a balanced ride and predictable braking.

Looking for Wheel Bearing with proven quality? Choose OEM Wheel Bearing. Mazda designs and builds them to strict factory specs. Every piece goes through rigorous quality checks. You'll get parts that fit right and work like new. Shop our huge inventory of OEM Mazda 626 parts. Enjoy the highly competitive prices online. Our site is your one-stop shop. Each genuine 626 part includes a manufacturer's warranty. Buy with confidence. Our return policy is simple and hassle-free. In a rush? Choose expedited delivery at checkout. You'll love the streamlined experience from search to checkout to receiving your order.

Mazda 626 Wheel Bearing Parts and Q&A

- Q: How to check and service vehicle wheel bearings on Mazda 626?A:With the vehicle securely supported on jackstands, spin the rear wheels to check for noise, rolling resistance, and free play. Grasp the top and bottom of the tire and move it in-and-out; if it moves more than 0.005-inch, the bearings should be checked and replaced if necessary. The front wheel bearings require disassembly of the front hub for servicing, while the rear wheel bearings can be serviced as routine maintenance. To repack, raise the rear of the vehicle and support it on jackstands, then remove the wheels. Use a chisel and hammer to dislodge the grease cap, remove the hub nut (which should be discarded), and pull the hub assembly out slightly before pushing it back to remove the outer bearing and washer. Pry the inner bearing seal out with a screwdriver, clean all parts with solvent, and inspect the bearings for defects. Use high-temperature wheel bearing grease to pack the bearings thoroughly, apply grease to the spindle, and place a small amount inboard of each bearing race. Install the grease-packed inner bearing and a new seal, lubricate the seal lip, and place the hub assembly onto the spindle. Install a new spindle nut and set the bearing preload by tightening the nut to the specified torque, rotating the hub, loosening the nut, measuring the torque at which the hub starts to turn, and then tightening the nut to the appropriate resistance. Crimp the collar of the nut into the spindle groove, pack the cap with grease, install it, and finally, reinstall the wheels and lower the vehicle.

Related Mazda 626 Parts

Browse by Year

2002 Wheel Bearing 2001 Wheel Bearing 2000 Wheel Bearing 1999 Wheel Bearing 1998 Wheel Bearing 1997 Wheel Bearing 1996 Wheel Bearing 1995 Wheel Bearing 1994 Wheel Bearing 1993 Wheel Bearing 1992 Wheel Bearing 1991 Wheel Bearing 1990 Wheel Bearing 1989 Wheel Bearing 1988 Wheel Bearing 1987 Wheel Bearing 1986 Wheel Bearing 1985 Wheel Bearing 1984 Wheel Bearing