×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

Genuine Mazda 929 Intake Valve

Engine Intake Valve- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Intake Valve found

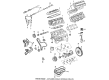

Mazda 929 Valves Part Number: JE0112111

Mazda 929 Intake Valve

Looking for Intake Valve with proven quality? Choose OEM Intake Valve. Mazda designs and builds them to strict factory specs. Every piece goes through rigorous quality checks. You'll get parts that fit right and work like new. Shop our huge inventory of OEM Mazda 929 parts. Enjoy the highly competitive prices online. Our site is your one-stop shop. Each genuine 929 part includes a manufacturer's warranty. Buy with confidence. Our return policy is simple and hassle-free. In a rush? Choose expedited delivery at checkout. You'll love the streamlined experience from search to checkout to receiving your order.

Mazda 929 Intake Valve Parts and Q&A

- Q: How to remove and install the intake valve in the cylinder head on Mazda 929?A:In order to install and remove the Cylinder Head, one has to remove the cylinder head and put it on an appropriate workstand first before installing it to the engine. Install a special Valve Spring Lifter and Pivot combination to the valve head and spring cap; otherwise, the Valve Spring Lifter may be installed, from the top side, with a substitute. Press the valve spring up to the point where the key pins can be removed and gradually unlock the valve spring and remove the spring retainer and the valve springs. Take the valve, pull the valve guide valve stem seal, invert the cylinder head and pull the valve. To install, pass the valve through the bore and put a trace of engine oil on the inner surface of the new valve stem seal tapping it on the valve guide. Install the valve spring and retainer and put over the valve stem and press the spring until the keeper groove comes open, install the keepers and then relieve the spring pressure. To inspect, clean all carbon off the valves, and examine them to determine any warpage, cracks, or excessive burning and replace any valve that cannot be cleaned satisfactorily. Measure the stem diameter at three positions and measure the inner diameter of valve guide at two positions to calculate the stem-to-guide clearance. When clearance is excessive, it may not be necessary to change either component, changing either a worn valve guide or a below-spec stem diameter valve can be enough. The measurements are also very important because when one component is overworn, then so will be the other component that is mating with it, thus the need to replace both parts. Once all the carbon deposits are cleared out of the combustion chambers before it is installed, new or reusable valves.