×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

Genuine Mazda Millenia Crankshaft Position Sensor

Engine Crankshaft Position Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Crankshaft Position Sensors found

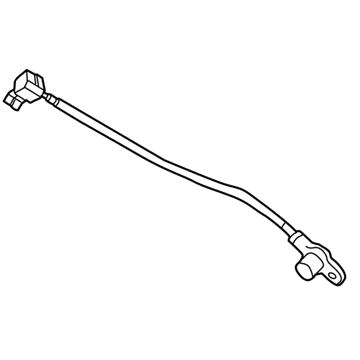

Mazda Millenia Crankshaft Position Sensor Part Number: KJ01-18-221

$140.64 MSRP: $187.56You Save: $46.92 (26%)Ships in 1-2 Business DaysMazda Millenia Crankshaft Position Sensor Part Number: KL47-18-221

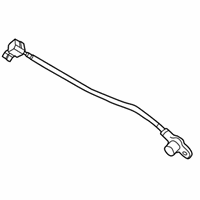

$125.46 MSRP: $167.32You Save: $41.86 (26%)Ships in 1-2 Business Days

Mazda Millenia Crankshaft Position Sensor

Looking for Crankshaft Position Sensor with proven quality? Choose OEM Crankshaft Position Sensor. Mazda designs and builds them to strict factory specs. Every piece goes through rigorous quality checks. You'll get parts that fit right and work like new. Shop our huge inventory of OEM Mazda Millenia parts. Enjoy the highly competitive prices online. Our site is your one-stop shop. Each genuine Millenia part includes a manufacturer's warranty. Buy with confidence. Our return policy is simple and hassle-free. In a rush? Choose expedited delivery at checkout. You'll love the streamlined experience from search to checkout to receiving your order.

Mazda Millenia Crankshaft Position Sensor Parts and Q&A

- Q: How does the crankshaft position sensor function and How to test, remove, and install it on Mazda Millenia?A:The sensor on the crankshaft measures the rotation speed of the crankshaft and with this data, the computer can determine engine timing sequences and apply this data with the camshaft position sensor to determine the correct injection of fuel and ignition timing. To check the sensor first unplug the wire harness plug, next hook up an ohmmeter to the sensor terminals A and B, the resistance should be checked between 520-580 ohms at 68°F (20°C); the sensor must be replaced in case the resistance is out of this range. Also, check air gap between crankshaft pulley and sensor, it must lie between 0.040-0.080 inches (1-2 mm), otherwise, check crankshaft pulley or change sensor. To remove and install, first disconnect the negative battery cable, and any accessory drive belts you may require removed in order to reach the sensor, and the engine oil dipstick tube may need to be removed. The next step is to remove the sensor attaching bolt and remove the sensor out of the engine, which must be installed in the opposite order of the removal.