×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

Genuine Mazda Millenia Drive Belt

Serpentine Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Drive Belts found

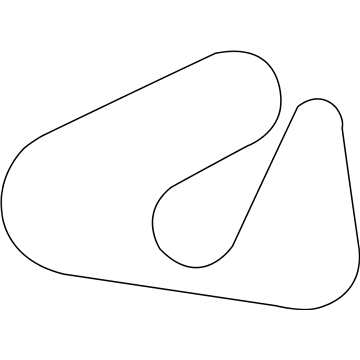

Mazda Millenia Serpentine Belt Part Number: KFC8-15-907

$20.26 MSRP: $27.02You Save: $6.76 (26%)Ships in 1-2 Business DaysMazda Millenia Serpentine Belt Part Number: KF33-15-907-9U

Mazda Millenia Drive Belt Part Number: KJ02-18-381B-9U

Mazda Millenia Drive Belt

Looking for Drive Belt with proven quality? Choose OEM Drive Belt. Mazda designs and builds them to strict factory specs. Every piece goes through rigorous quality checks. You'll get parts that fit right and work like new. Shop our huge inventory of OEM Mazda Millenia parts. Enjoy the highly competitive prices online. Our site is your one-stop shop. Each genuine Millenia part includes a manufacturer's warranty. Buy with confidence. Our return policy is simple and hassle-free. In a rush? Choose expedited delivery at checkout. You'll love the streamlined experience from search to checkout to receiving your order.

Mazda Millenia Drive Belt Parts and Q&A

- Q: What are the key considerations for inspecting and adjusting accessory drive belts on Mazda Millenia?A:When checking the accessory drive bells, there are usually three types that are observed on the cars today with a healthy drive bell exhibiting no deep cracks since it may result in flex and accumulation of heat which may cause the belt to break. Critical reinforcing cords are exposed to excessive wear through worn covers, and it is possible to wear or break serious cords through the use of a bell that is too wide. Belts are to be examined as to glazing or cracking, glazed belt feeling smooth due to the slippery nature whereas a good belt has a slight texture of the fabric or fabric. The cracks normally begin at the inner edge and run out and this makes replacement of any worn or damaged drive belts at once or rather all at once a precautionary measure. The alternator belt ought to be tested to confirm that it has the right tension by pressing on the belt, and when purchasing a new or used belt, there are particular tolerances of deflection of the assembly. In case of any adjustments, loosen the adjustment bolt and through bolt of the alternator then the adjustment screw is to be turned to a desired tension which should be clamped using given torque values. The same method is used to the power steering and air conditioning belts and bolts are loosened and a porybar is used to attain the right amount of tension. The process of installing or removing of belts is described in specific steps depending on the type of engine with detailed torque requirements given to connect bolts once they have been adjusted. Removal of belts involves it being important to remember the direction of belts and obey the instructions of installation to be able to install new or recycled belts correctly.