×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

Genuine Mazda MX-5 Miata Clutch Master Cylinder

- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Clutch Master Cylinders found

Mazda MX-5 Miata Master Cylinder Part Number: NA1J-41-400

$137.11 MSRP: $182.85You Save: $45.74 (26%)Ships in 1-2 Business DaysMazda MX-5 Miata Master Cylinder Part Number: NE51-41-990A

$137.33 MSRP: $183.14You Save: $45.81 (26%)Ships in 1-2 Business Days

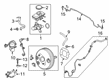

Mazda MX-5 Miata Clutch Master Cylinder

Looking for Clutch Master Cylinder with proven quality? Choose OEM Clutch Master Cylinder. Mazda designs and builds them to strict factory specs. Every piece goes through rigorous quality checks. You'll get parts that fit right and work like new. Shop our huge inventory of OEM Mazda MX-5 Miata parts. Enjoy the highly competitive prices online. Our site is your one-stop shop. Each genuine MX-5 Miata part includes a manufacturer's warranty. Buy with confidence. Our return policy is simple and hassle-free. In a rush? Choose expedited delivery at checkout. You'll love the streamlined experience from search to checkout to receiving your order.

Mazda MX-5 Miata Clutch Master Cylinder Parts and Q&A

- Q: What steps should be taken before rebuilding or replacing the Clutch Master Cylinder on Mazda MX-5 Miata?A:Prior to starting this process, it is advisable to contact the local parts stores and dealer service departments in regards to a rebuild kit or new master cylinder purchase since the parts required to do the rebuild may be available at a low cost or the replacement may be a costly one. In case you choose to remanufacture the cylinder, look into the bore. In models of 2005 and earlier, open the hood and stuff rags under the clutch master cylinder, being careful to wipe off all the spilled-out clutch fluid with soapy water. Unscrew the hydraulic line at the clutch master cylinder with a flare nut wrench, carefully not to round-off the nut, and then remove the nuts connecting the master cylinder to the firewall and slide it out. Invert the master cylinder to remove fluid trapped, and place it in a vise with the piston end facing up. Using a Phillips screwdriver, press the piston down and clean the snap-ring off with snap-ring pliers and do not damage the pushrod contact surface. Hammer the master cylinder on a block of wood to force out the piston, the spacer, the primary cup, the spring and remove the seal on the piston very carefully. Check the bore deep scratches or ridges, at least, should not be present; otherwise change the master cylinder. In case of rebuilding, wipe all reusable parts with brake cleaner or denatured alcohol and apply a new seal to the piston with the seal lips facing away at the pushrod end, use the parts in the rebuild kit. Apply new brake fluid to the bore and parts and insert into the bore of the cylinder and replace snap-ring. To install, grease the pushrod end slightly, clamp the master cylinder against the firewall and thread the hydraulic line without crossing threads. screw the mounting nuts and hydraulic line fitting correctly, fill in the clutch/brake fluid reservoir with brake fluid that meets DOT specifications 3 and bleed the clutch system. In the case of 2006 and subsequent models, follow the instructions up to the point of removing the hose by taking off the hood and placing rags under the clutch master cylinder and unscrewing the required hoses. The knee bolster trim panel inside the vehicle can be taken off and the mounting nuts of the master cylinder are to be found to be removed before removing the master cylinder. In case of a rebuilding, the procedure is also the same as in previous models, and it is important to thoroughly tighten the master cylinder mounting nuts to the required torque when re-fitting them, otherwise, the procedure is the opposite of dismantling.

Related Mazda MX-5 Miata Parts

Browse by Year

2022 Clutch Master Cylinder 2021 Clutch Master Cylinder 2020 Clutch Master Cylinder 2019 Clutch Master Cylinder 2018 Clutch Master Cylinder 2017 Clutch Master Cylinder 2016 Clutch Master Cylinder 2015 Clutch Master Cylinder 2014 Clutch Master Cylinder 2013 Clutch Master Cylinder 2012 Clutch Master Cylinder 2011 Clutch Master Cylinder 2010 Clutch Master Cylinder 2009 Clutch Master Cylinder 2008 Clutch Master Cylinder 2007 Clutch Master Cylinder 2006 Clutch Master Cylinder