×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

Genuine Mazda Protege Axle Shaft

Car Axle Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

21 Axle Shafts found

Mazda Protege Axle Shafts Part Number: FA56-25-700A

$188.20 MSRP: $250.98You Save: $62.78 (26%)Ships in 1-2 Business DaysMazda Protege Axle Shafts Part Number: FA54-25-700B

$189.85 MSRP: $253.19You Save: $63.34 (26%)Ships in 1-2 Business DaysMazda Protege Shaft Part Number: F055-25-700B

$275.44 MSRP: $367.33You Save: $91.89 (26%)Ships in 1-2 Business DaysMazda Protege Shaft Part Number: F047-25-700

$361.90 MSRP: $482.63You Save: $120.73 (26%)Ships in 1-2 Business DaysMazda Protege Shaft Part Number: F037-25-700

$373.06 MSRP: $497.52You Save: $124.46 (26%)Ships in 1-2 Business DaysMazda Protege Drive Axle Part Number: F063-25-500R-0E

$26.50 MSRP: $34.79You Save: $8.29 (24%)Ships in 1-2 Business DaysMazda Protege Drive Axle Part Number: F069-25-600R-0D

$26.77 MSRP: $35.14You Save: $8.37 (24%)Ships in 1-2 Business DaysMazda Protege Axle Assembly Part Number: FA52-25-60XR-0C

$117.06 MSRP: $153.65You Save: $36.59 (24%)Ships in 1-2 Business DaysMazda Protege Axle Assembly Part Number: FA53-25-50XA

$77.30 MSRP: $101.47You Save: $24.17 (24%)Ships in 1-2 Business DaysMazda Protege Axle Shafts Part Number: FA55-25-700B

Mazda Protege Shaft Part Number: F056-25-700C

Mazda Protege Axle Shafts Part Number: GA15-25-700C

Mazda Protege Axle Assembly Part Number: FA73-25-50XR-0A

Mazda Protege Axle Shafts Part Number: T005-27-270B

Mazda Protege Axle Shafts Part Number: FA57-25-700A

Mazda Protege Axle Assembly Part Number: FA61-25-600R-0A

Mazda Protege Axle Assembly Part Number: FA61-25-60XR-00

Mazda Protege Axle Assembly Part Number: FA78-25-50XR-0A

Mazda Protege Drive Axle Part Number: FS17-25-600R-0F

Mazda Protege Drive Axle Part Number: FZ01-25-40XR-0B

| Page 1 of 2 |Next >

1-20 of 21 Results

Mazda Protege Axle Shaft

Looking for Axle Shaft with proven quality? Choose OEM Axle Shaft. Mazda designs and builds them to strict factory specs. Every piece goes through rigorous quality checks. You'll get parts that fit right and work like new. Shop our huge inventory of OEM Mazda Protege parts. Enjoy the highly competitive prices online. Our site is your one-stop shop. Each genuine Protege part includes a manufacturer's warranty. Buy with confidence. Our return policy is simple and hassle-free. In a rush? Choose expedited delivery at checkout. You'll love the streamlined experience from search to checkout to receiving your order.

Mazda Protege Axle Shaft Parts and Q&A

- Q: How to remove and install an axle shaft on Mazda Protege?A:To unscrew the axle shaft, disconnect the cable in the negative terminal of the battery first but have the correct set of the activation code of any anti-theft system just in case. Parking brake, then loosen the lug nuts in the front wheel, unstake the axle shaft hub lock nut and lift the vehicle and remove the wheels. Prevent the hub turning by prying between the studs of a wheel with a piece of pry bar until the axle shaft hub lock nut is removed. Use the soft faced hammer or a brass punch and tap the end of the axle shaft to loosen it out of the splines of the hub, taking care not to force it through the hub and damage it. In case of being stuck, it may be required to remove the brake disc. The next step is to take off the engine splash shield(s), the nut bolt that attaches the stabilizer bar to the control arm, unscrew the tie-rod of the steering knuckle and the lower ball joint of the control arm. Unscrew the steering knuckle to disconnect the axle shaft with the hub, and hold the outer end to avoid damaging the inner CV Joint. Put under the transaxle a drain pan to collect the lubricant and loosen the inner CV joint of the transaxle by using a pry. To install, reverse the uninstall procedure, being sure to install a new clip on the inner CV joint, grease the splines, and wipe the transaxle oil seal with oil. Install a new hub lock nut and tighten it to the recommended torque, install the wheel and lug nuts then push the axle shaft sharply to seat the clip then check the level of transaxle lubricant (adding more as needed).

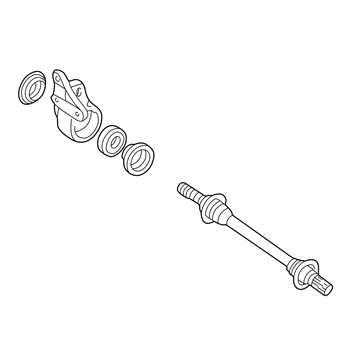

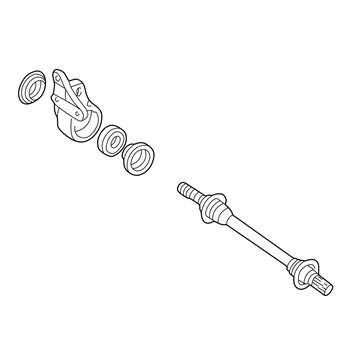

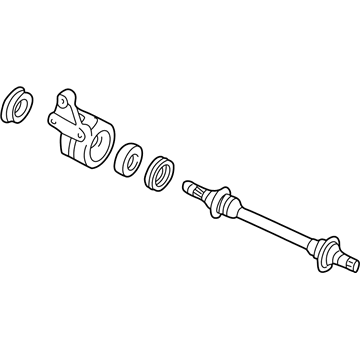

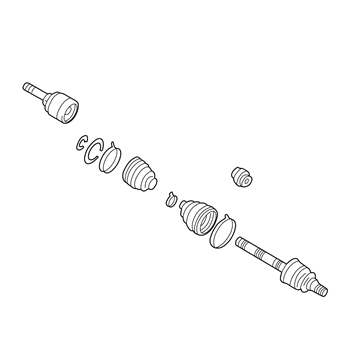

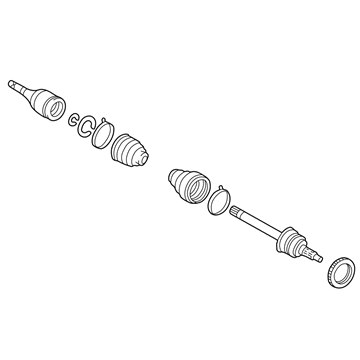

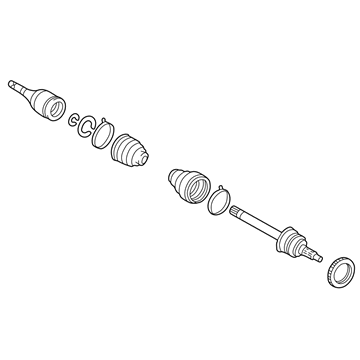

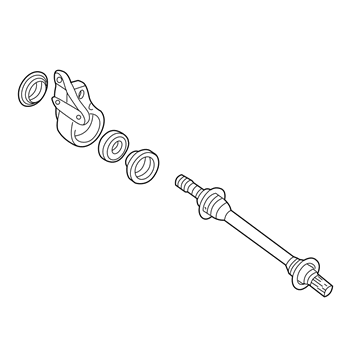

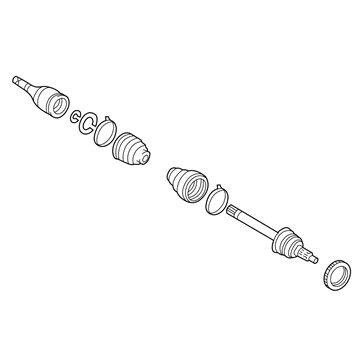

- Q: How is power transmitted from the transaxle to the wheels via the axle shaft on Mazda Protege?A:The transaxle is took through to the wheels through two axle shafts, the inner ends of which are splined into the gears of the differential, and the outer ones are splined to the axle hubs, and held by a large lock nut. The inner ends have sliding constant velocity joints, which permit both angular and axial movement, including a tripod bearing, and a joint housing, which permit the slide as the axle shaft passes with the wheel. These joints are removable and washable in case a boot is faulty but damaged components should be totally replaced. The ball joint type of the outer CV Joints has ball bearings that are located in an inner race and an outer cage that allow angular but not an axial movement. Although outer joints may be cleaned, checked up, and repacked, they must not be taken apart, but in case of damage, the whole joint must be replaced with the axle shaft as one component. The 1.8L DOHC engine vehicles also have an intermediate joint shaft installed between the transaxle and right axle shaft and it is supported by a bracket at its outer end. The boots should be regularly examined to check their damages and any leakages of lubricant since torn CV joint boots should be replaced immediately to avoid damages to the joint. Replacement of boots normally involves removal of axle shaft but replacement boots of the split type are available in some auto part shops and can be fitted without the need to remove axle shaft. It is, however, a good practice to take off the axle shaft and strip off the CV joint to completely cleanse it to get rid of any contaminants that would hasten the wear. Worn or damaged CV joints are common and are characterized by leaks of lubricants, clicking sounds during any turns, clunks of acceleration following coasting, and vibrations at the highway speeds. Checking wear Measure each axle separately and turn it, with the CV joint housings in hand, feeling a play in the joints that shows lost splines or loose joints, and also checking the axle shaft with cracks, dents, and distortion.