×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

Genuine Mazda Protege Battery Cables

Battery Cable- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 Battery Cables found

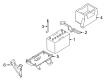

Mazda Protege Engine Harness Part Number: BJ0T-67-070A

$279.73 MSRP: $373.04You Save: $93.31 (26%)Ships in 1-2 Business DaysMazda Protege Positive Cable Part Number: BN5V-67-070

$280.48 MSRP: $374.04You Save: $93.56 (26%)Mazda Protege Engine Harness Part Number: BJ0K-67-070A

Mazda Protege Wire Harness Part Number: BB7A-67-070C

Mazda Protege Negative Cable Part Number: BC1D-67-EW1B

Mazda Protege Positive Cable Part Number: BG1N-67-070A

Mazda Protege Engine Harness Part Number: BJ0E-67-070B

Mazda Protege Battery Cables

Looking for Battery Cables with proven quality? Choose OEM Battery Cables. Mazda designs and builds them to strict factory specs. Every piece goes through rigorous quality checks. You'll get parts that fit right and work like new. Shop our huge inventory of OEM Mazda Protege parts. Enjoy the highly competitive prices online. Our site is your one-stop shop. Each genuine Protege part includes a manufacturer's warranty. Buy with confidence. Our return policy is simple and hassle-free. In a rush? Choose expedited delivery at checkout. You'll love the streamlined experience from search to checkout to receiving your order.

Mazda Protege Battery Cables Parts and Q&A

- Q: How should you periodically inspect and replace battery cables to ensure proper engine performance on Mazda Protege?A:Periodically check the full length of every battery cable to detect damage, broken or burnt insulations, corrosion due to low sticking or corrosion of connections may cause problems with the machine starting and loss of engine performance. Inspect the cable-to-terminal connections by checking them to determine the presence of cracks, loose wire strands, and corrosion; if there are white, fluffy deposits beneath the insulation, then the connections are corroded and require replacement. It is also important to ensure that when removing cables, the negative cable would be disconnected first and last to ensure that the battery is not shorted. Unplug the former cables out of the battery, following them to their opposite ends, in order to remove them out of the starter solenoid and ground connector, observing the route to follow them properly. In case of replacement, bring the old ones along so that the same parts can be taken since the positives ones are usually in red and bigger, whereas ground ones are usually in black and smaller. Use a wire brush to clean the threads of the solenoid or ground connection by cleaning away any rust and corrosion and grease it with a light coating of battery terminal corrosion inhibitor or petroleum jelly to avoid future problems. Connect the cable to the solenoid or ground connection, and screw the mounting nut or bolt. Prior to attaching a new cable to the battery, it must fit into the battery post exactly as it is, without being stretched, firstly the positive cable, then the negative cable.