×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

Genuine Mazda MPV Brake Hose

Brake Line- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

12 Brake Hoses found

Mazda MPV Brake Line Part Number: LC62-43-650A

$2.04 MSRP: $2.68You Save: $0.64 (24%)Ships in 1-2 Business DaysMazda MPV Flex Hose Part Number: LC62-43-980B

$38.44 MSRP: $51.27You Save: $12.83 (26%)Ships in 1-2 Business DaysMazda MPV Flex Hose Part Number: LE44-43-820C

$49.90 MSRP: $66.55You Save: $16.65 (26%)Ships in 1-2 Business DaysMazda MPV Flex Hose Part Number: LC62-43-810B

$31.55 MSRP: $42.07You Save: $10.52 (26%)Ships in 1-2 Business DaysMazda MPV Flex Hose Part Number: S121-43-820

$27.51 MSRP: $36.69You Save: $9.18 (26%)Ships in 1-2 Business DaysMazda MPV Flex Hose Part Number: S231-43-820

$4.83 MSRP: $36.57You Save: $31.74 (87%)Ships in 1-2 Business DaysMazda MPV Flex Hose Part Number: LA12-43-980A

$12.31 MSRP: $74.53You Save: $62.22 (84%)Ships in 1-2 Business DaysMazda MPV Flex Hose Part Number: LA01-43-980A

$12.19 MSRP: $16.00You Save: $3.81 (24%)Ships in 1-2 Business DaysMazda MPV Flex Hose Part Number: LB52-43-820B

$11.71 MSRP: $15.37You Save: $3.66 (24%)Ships in 1-2 Business DaysMazda MPV Flex Hose Part Number: LE44-43-810C

$8.36 MSRP: $10.97You Save: $2.61 (24%)Ships in 1-2 Business DaysMazda MPV Flex Hose Part Number: LB40-43-820B

Mazda MPV Brake Line Part Number: LC62-43-660A

Mazda MPV Brake Hose

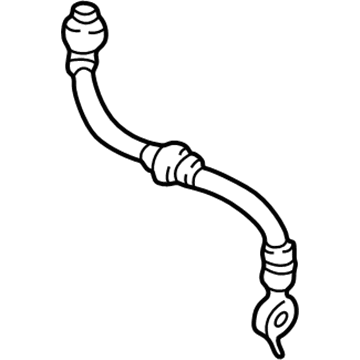

Looking for Brake Hose with proven quality? Choose OEM Brake Hose. Mazda designs and builds them to strict factory specs. Every piece goes through rigorous quality checks. You'll get parts that fit right and work like new. Shop our huge inventory of OEM Mazda MPV parts. Enjoy the highly competitive prices online. Our site is your one-stop shop. Each genuine MPV part includes a manufacturer's warranty. Buy with confidence. Our return policy is simple and hassle-free. In a rush? Choose expedited delivery at checkout. You'll love the streamlined experience from search to checkout to receiving your order.

Mazda MPV Brake Hose Parts and Q&A

- Q: How should brake hoses and lines be inspected and replaced on Mazda MPV?A:According to the maintenance plan and each time a vehicle is hoisted, brake hoses and lines are to be checked. In replacement, the process is applicable to either of the front brake hose between the bracket on the wheel well and the caliper or the single rear hose between the bracket on the underside of the body and the bracket on the top of the axle housing. Start by pulling off the U-clip into the bracket with pliers. To unattach a front brake hose to a metal brake line, detach the U-clip of the bracket on the wheel well, and still with a backup wrench, detach the threaded connection between the hose and the line. In the case of rear brake hose, the hose needs to be stripped off the threaded connection between the hose and the line, unscrew the U-clip out of the bracket on the underside of the body. Disconnect the hose to the bracket, then disconnect the brake line to the hose fitting with the help of a backup wrench. Take out the U-clip in the strut housing and remove the hose in the bracket. Unscrew the inlet banjo bolt on the caliper, and dispose of the sealing washers. Installation of the new hose involves use of a new sealing washer on either side of the hose fitting, installation of an inlet banjo bolt and then ensuring it is tightened. Insert the hose in the strut-housing bracket and fix it using the U-clip. And without twisting the hose, place the hose fitting into the frame bracket and apply a backup wrench to attach the brake line to the hose fitting. Fit the U-clip holding the female fitting to the frame bracket. Make sure that the hose is not kinked and it does not touch any section of the suspension by rotating the wheels to the left and right extremes. In case of contact, take away the hose and reassemble the installation. Once installed, ensure that the master cylinder fluid is at the correct level and fill it up accordingly and then bleed the brakes by loosening the system and checking the brakes before driving. In the replacement of metal brake lines, one must use the proper parts and should not use copper tubing on any part of the brake system. Real steel brake lines can be bought at a dealer parts department or auto parts store, and ready-to-assemble brake lines with flared tube ends and fitted fittings can as well be bought. Make sure that the new line is firmly clamped in the brackets and has a proper clearance of moving or hot parts. Once installed, ensure that the master cylinder fluid is at the correct level and fill it up accordingly and then bleed the brakes by loosening the system and checking the brakes before driving.