×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

Genuine Mazda MPV Brake Master Cylinder

- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Brake Master Cylinders found

Mazda MPV Master Cylinder Part Number: LA01-43-400R-0D

$27.50 MSRP: $36.09You Save: $8.59 (24%)Ships in 1-2 Business DaysMazda MPV Master Cylinder Part Number: LC70-43-40ZR-0B

Mazda MPV Master Cylinder Part Number: LD47-43-400A

Mazda MPV Master Cylinder Part Number: LE44-43-400R-00

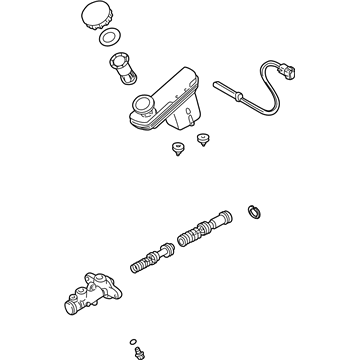

Mazda MPV Brake Master Cylinder

Looking for Brake Master Cylinder with proven quality? Choose OEM Brake Master Cylinder. Mazda designs and builds them to strict factory specs. Every piece goes through rigorous quality checks. You'll get parts that fit right and work like new. Shop our huge inventory of OEM Mazda MPV parts. Enjoy the highly competitive prices online. Our site is your one-stop shop. Each genuine MPV part includes a manufacturer's warranty. Buy with confidence. Our return policy is simple and hassle-free. In a rush? Choose expedited delivery at checkout. You'll love the streamlined experience from search to checkout to receiving your order.

Mazda MPV Brake Master Cylinder Parts and Q&A

- Q: How to remove and install the Brake Master Cylinder on Mazda MPV?A:To change or install the master cylinder, you will first have to depress the brake pedal a few times to push the air out of the Brake Booster before unplugging the electrical connector of the fluid level sensor. Unscrew the primary and secondary outlet port brake lines of the master cylinder, plug the ends to stop entry of dirt, moisture and place the newspapers under to receive any spilled brake fluid. Disassembly Be careful not to spill bakke fluid on painted parts, remove the nuts that hold the master cylinder in place, and remove the master cylinder. To install, do the opposite, with one thing, be sure to bleed the whole hydraulic system before handing it back. Fill the master cylinder, and bleed by loosening all the plugs and flushing out the piston assembly to force out all the air, repeat until only the brake fluid comes out. Fill up the reservoirs, and fit diaphragm and cap, and bleed the brake system. Check the clearance of the pushrod using a hand-held vacuum pump and make adjustments when needed then test the brakes. Provided master cylinder is to be overhauled, initial check items include availability of a new or rebuilt unit and a rebuild kit. Wipe down the outside, take off the reservoir cap and empty out the remaining fluid. Clamp the master cylinder with a vise, forcing the piston assembly down, and scraping off the snap-ring to extract the primary piston assembly, checking seals, which should not be damaged. Disassemble the secondary piston assembly, and may invert the cylinder to push it out, and check to see if there are any leaks around the reservoir grommets. In case of damages to seals, change them and examine the cylinder bore and pistons with regard to corrosion or wear changing the assembly in the event of necessity. In case the parts are not worn out, buy a repair package and clean all internal parts with clean brake fluid or denatured alcohol. Apply brake fluid to fresh seals, insert them into the master cylinder and examine the reservoir of the master cylinder. Reservoir and master cylinder are then assembled and the bore lubricated and then the secondary piston assembly then the primary piston assembly is assembled and then the snap-ring placed in its proper position before bench bleeding the master cylinder.

Related Mazda MPV Parts

Browse by Year

2006 Brake Master Cylinder 2005 Brake Master Cylinder 2004 Brake Master Cylinder 2003 Brake Master Cylinder 2002 Brake Master Cylinder 2001 Brake Master Cylinder 2000 Brake Master Cylinder 1995 Brake Master Cylinder 1994 Brake Master Cylinder 1993 Brake Master Cylinder 1992 Brake Master Cylinder 1991 Brake Master Cylinder 1990 Brake Master Cylinder 1989 Brake Master Cylinder