×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

Genuine Mazda MPV Drive Belt

Serpentine Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

11 Drive Belts found

Mazda MPV Serpentine Belt Part Number: AJ04-15-908

$19.39 MSRP: $25.85You Save: $6.46 (25%)Ships in 1-2 Business DaysMazda MPV Serpentine Belt Part Number: AJ03-18-381

$15.34 MSRP: $20.45You Save: $5.11 (25%)Ships in 1-2 Business DaysMazda MPV Alternator Belt Part Number: G601-18-381-9U

$27.11 MSRP: $36.16You Save: $9.05 (26%)Ships in 1-2 Business DaysMazda MPV Alternator Belt Part Number: 8397-18-381A

$2.65 MSRP: $3.48You Save: $0.83 (24%)Ships in 1-2 Business DaysMazda MPV Alternator Belt Part Number: JE57-18-381A-9U

$18.93 MSRP: $25.24You Save: $6.31 (25%)Ships in 1-2 Business DaysMazda MPV A/C Belt Part Number: JE17-15-908

$1.71 MSRP: $2.25You Save: $0.54 (24%)Ships in 1-2 Business DaysMazda MPV Alternator Belt Part Number: JF01-18-381A-9U

$3.81 MSRP: $5.00You Save: $1.19 (24%)Ships in 1-2 Business DaysMazda MPV Power Steering Belt Part Number: B611-15-908A

Mazda MPV A/C Belt Part Number: G603-15-908

Mazda MPV Water Pump Belt Part Number: GY01-15-908A

Mazda MPV Drive Belt Part Number: GY02-15-908-9U

Mazda MPV Drive Belt

Looking for Drive Belt with proven quality? Choose OEM Drive Belt. Mazda designs and builds them to strict factory specs. Every piece goes through rigorous quality checks. You'll get parts that fit right and work like new. Shop our huge inventory of OEM Mazda MPV parts. Enjoy the highly competitive prices online. Our site is your one-stop shop. Each genuine MPV part includes a manufacturer's warranty. Buy with confidence. Our return policy is simple and hassle-free. In a rush? Choose expedited delivery at checkout. You'll love the streamlined experience from search to checkout to receiving your order.

Mazda MPV Drive Belt Parts and Q&A

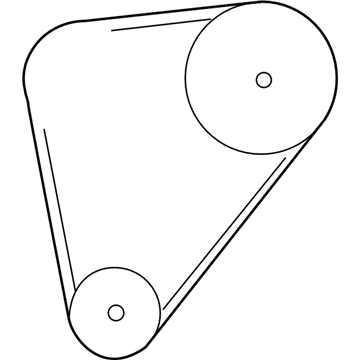

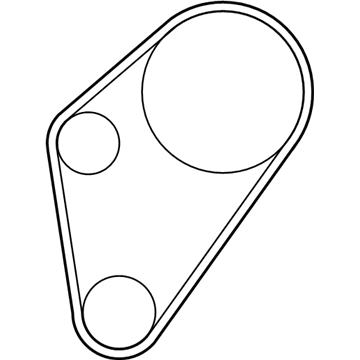

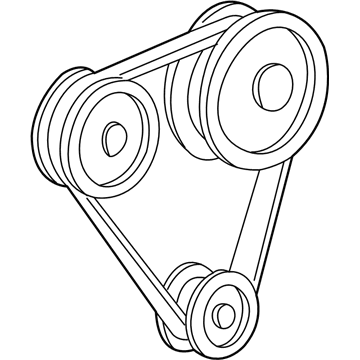

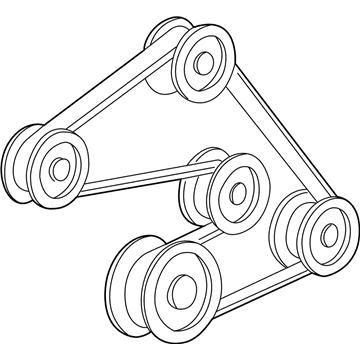

- Q: What are the functions and maintenance requirements of drive belts on Mazda MPV?A:The drivebelts or Vbelts or the fan belts are located in the front of the engine and plays a significant role in the functioning of the vehicle as well as its part. The nature of these belts and the material used makes them prone to failure with passing time and they need a regular check-up and tightening to prevent serious engine damage. Belts are different depending on the installed accessories because they drive such components as the alternator, power steering pump, water pump, and air conditioning compressor, whereby one belt may be powering more than one component depending on the pulley system provided. In order to examine the belts, when the engine is off, open the hood and examine the belts by feeling along the belt and make sure to inspect the opposite side by twisting the other belt. The tension in the belt is determined by pushing with thumb to determine the extent to which the belt deflects and a typical deflection is 1/4 inch when the distance between pulleys is 7 to 11 inches and 1/2 inch when the distance is 12 to 16 inches. When it is necessary to adjust, the tension is adjustable by sliding the belt-driven accessory on its bracket, and this requires rape of an adjusting bolt and a pivot bolt on each part. The component can be relaxed then brought to adjust the tension of the belt after which the bolts must be fixed once the right tension is attained. Leverage might be needed in this process, but it must not be used in a way that will damage any parts. To replace the belt, the same adjustment procedure is undertaken, however the belt has to be totally removed off the pulleys. Where two or more belts are involved, replacement of all the belts is recommended at once and each belt and the pulley groove should be marked for correct installation. The purchase of the new belts should be accompanied by the old ones so that the right comparisons can be made concerning the length, width, and design.