×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

Genuine Mazda MPV Rod Bearing

Engine Connecting Rod Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Rod Bearings found

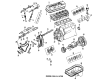

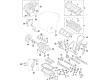

Mazda MPV Bearing Set Part Number: FEYA-11-SE0

$18.57 MSRP: $24.37You Save: $5.80 (24%)Ships in 1-2 Business DaysMazda MPV Bearing Part Number: AJ57-11-225

Mazda MPV Rod Bearing

Looking for Rod Bearing with proven quality? Choose OEM Rod Bearing. Mazda designs and builds them to strict factory specs. Every piece goes through rigorous quality checks. You'll get parts that fit right and work like new. Shop our huge inventory of OEM Mazda MPV parts. Enjoy the highly competitive prices online. Our site is your one-stop shop. Each genuine MPV part includes a manufacturer's warranty. Buy with confidence. Our return policy is simple and hassle-free. In a rush? Choose expedited delivery at checkout. You'll love the streamlined experience from search to checkout to receiving your order.

Mazda MPV Rod Bearing Parts and Q&A

- Q: What essential steps and considerations should be taken for Rod Bearing replacement and inspection during an engine overhaul on Mazda MPV?A:When performing an engine overhaul, replacement of the main and connecting rod bearings with new ones and the retention of the old ones to be examined is necessary because they can give insight on the engine. Failure bearing may be as a result of many causes, such as, lack of lubrication, dirt contamination, overloading, and corrosion, all of which should be resolved to avoid reoccurrence upon reassembling the engine. In the process of inspecting the bearings, they are to be taken out of their positions, and placed on a clean surface to aid in matching any issues with the crankshaft journal. The contaminants may enter the engine during the assembly, via filters, or via PCV system and it may contain metal chips, abrasives that were left behind in machine work or improper cleaning. These foreign objects could be embedded in the bearing material whereas the larger particles could create scoring or gouging. In order to avoid these failures, it is important to clean all the parts thoroughly and replace oil and filters at regular intervals. Without lubrication may be due to too much heat, overloading, leaked oil, or blocked oil passages, which causes serious damage of the bearing material wiped away or extruded. The driving habits also make a major influence on bearing life; an example is full throttle when at low speeds, high loads are created and squeeze the oil film, and short trips may cause corrosion because of the inadequate heat to influence the evaporation of moisture and gases. Also improperly fit bearings will lead to oil starvation or high spots which will lead to failure.