×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

Genuine Mazda MX-5 Miata Wheel Bearing

Hub Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Wheel Bearings found

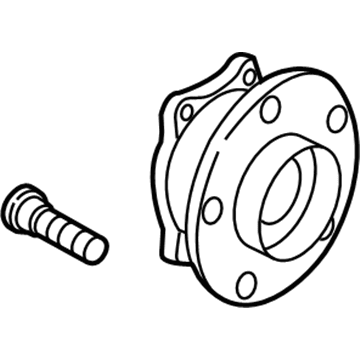

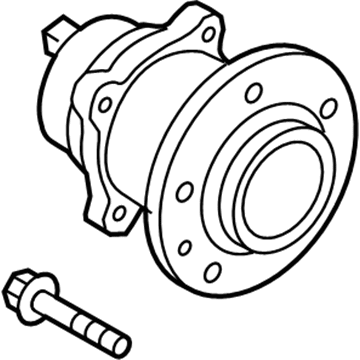

Mazda MX-5 Miata Wheel Bearing Part Number: FB01-26-151C-MV

$59.31 MSRP: $79.10You Save: $19.79 (26%)Ships in 1-2 Business DaysMazda MX-5 Miata Wheel Bearing Part Number: FB01-26-151F

$159.15 MSRP: $212.25You Save: $53.10 (26%)Ships in 1-2 Business DaysMazda MX-5 Miata Hub Assembly Part Number: N243-33-04X

$256.00 MSRP: $341.40You Save: $85.40 (26%)Ships in 1-2 Business DaysMazda MX-5 Miata Hub Assembly Part Number: NE51-33-04XA

$377.43 MSRP: $507.41You Save: $129.98 (26%)Ships in 1-2 Business Days

Mazda MX-5 Miata Wheel Bearing

Looking for Wheel Bearing with proven quality? Choose OEM Wheel Bearing. Mazda designs and builds them to strict factory specs. Every piece goes through rigorous quality checks. You'll get parts that fit right and work like new. Shop our huge inventory of OEM Mazda MX-5 Miata parts. Enjoy the highly competitive prices online. Our site is your one-stop shop. Each genuine MX-5 Miata part includes a manufacturer's warranty. Buy with confidence. Our return policy is simple and hassle-free. In a rush? Choose expedited delivery at checkout. You'll love the streamlined experience from search to checkout to receiving your order.

Mazda MX-5 Miata Wheel Bearing Parts and Q&A

- Q: Should a professional mechanic handle the pressing of the wheel bearing and wheel hub from the rear knuckle on Mazda MX-5 Miata?A:Due to the special tools and expertise required to press the hub and bearing from the rear knuckle, this job should be left to a professional mechanic. However, the knuckle and hub can be removed, and the assembly taken to a dealer service department or other repair shop for further assistance.

- Q: How to remove and inspect front wheel bearings in the wheel hub assembly on Mazda MX-5 Miata?A:The hub and bearing assembly includes the front wheel bearings which do not have a separate service. To start removal, loosen the lug nuts of the wheels, jack up the car and place it safely on jackstands then remove the wheel. Then take out the caliper disc, brake caliper and caliper bracket. Check the endplay of the hub and bearing assembly with a dial indicator against the hub, putting the indicator to zero with the hub pressed in, and recording the reading when the hub is pulled out. In case the endplay is greater than 0.002 inch, loosen the locknut and attempt to re-tighten the locknut to the required specifications. In case this fails to bring the endplay within reach, then the whole hub will have to be changed. When excess endplay is fixed by retightening, the retightened locknut should not be reused but a new one should be fixed. Take off grease cap on the hub, bend back the staked part of the locknut and open it. In case of re-tightening the locknut, remove it, then grind off the staked area then apply correct torque. Removing the bearing and hub assembly off the spindle, with a puller, as required; remove the brake disc shield bolts, as required. To check, feel the bearings in the hub, roughness, looseness, noise, greasy discharge etc.: spin with your fingers to feel. In case of any problems detected or grease leakage, change the hub and bearings. Also, inspect the wheel studs and the ABS sensor ring to check whether they are damaged, which can be repaired in the automotive machine shop. To install, do the reverse of the procedures, but be sure to apply wheel bearing grease and lubricate the spindle, re-fit a fresh locknut, tighten it to the appropriate torque and stake the locknut to ensure it does not loosen.

Related Mazda MX-5 Miata Parts

Browse by Year

2023 Wheel Bearing 2022 Wheel Bearing 2021 Wheel Bearing 2020 Wheel Bearing 2019 Wheel Bearing 2018 Wheel Bearing 2017 Wheel Bearing 2016 Wheel Bearing 2015 Wheel Bearing 2014 Wheel Bearing 2013 Wheel Bearing 2012 Wheel Bearing 2011 Wheel Bearing 2010 Wheel Bearing 2009 Wheel Bearing 2008 Wheel Bearing 2007 Wheel Bearing 2006 Wheel Bearing