×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

Genuine Mazda MX-6 Drive Belt

Serpentine Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 Drive Belts found

Mazda MX-6 Power Steering Belt Part Number: FS05-15-907

$20.59 MSRP: $27.46You Save: $6.87 (26%)Ships in 1-2 Business DaysMazda MX-6 Alternator Belt Part Number: FS12-18-381A

Mazda MX-6 Drive Belt Part Number: KLG4-15-908

Mazda MX-6 Alternator Belt Part Number: F201-18-381A-9U

Mazda MX-6 Power Steering Belt Part Number: F230-15-909

Mazda MX-6 Drive Belt Part Number: FS12-15-909A

Mazda MX-6 Alternator Belt Part Number: KL11-18-381B

Mazda MX-6 Drive Belt

Looking for Drive Belt with proven quality? Choose OEM Drive Belt. Mazda designs and builds them to strict factory specs. Every piece goes through rigorous quality checks. You'll get parts that fit right and work like new. Shop our huge inventory of OEM Mazda MX-6 parts. Enjoy the highly competitive prices online. Our site is your one-stop shop. Each genuine MX-6 part includes a manufacturer's warranty. Buy with confidence. Our return policy is simple and hassle-free. In a rush? Choose expedited delivery at checkout. You'll love the streamlined experience from search to checkout to receiving your order.

Mazda MX-6 Drive Belt Parts and Q&A

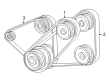

- Q: What are the functions and maintenance requirements of drive belts on Mazda MX-6?A:The drivebelts also referred to as the V-belts are located in the front of the engine and play very important roles to the running of the vehicle and its components. These belts are vulnerable to premature wear and tear due to their purpose and the material structure, therefore, they need to be checked and realigned regularly to prevent serious damage to the engine. Cars use ribbed belts of a particular design, and they should always be substituted with the same. Depending on the accessories installed, drivebelts are charged with the duty of moving the generator/alternator, the power steering pump, the water pump, and the air conditioning compressor and there may be only one belt supplying power to several parts depending on the pulley system installed. The three belt types used are Type 1 (alternator), Type 2 (both the power steering pump and the alternator) and Type 3, a type of serpentine belt that uses an idler pulley to ensure tension. In order to inspect the belts, it is suggested that one open the hood when the engine is off, and find the belts at the front and feel along the belts and twist them to check the underside of them. The belt tension is evaluated by pushing the belt at the mid point between the pulleys and noted deflection is compared to the required standards. Tension adjustment of the belt requires that each component has an adjusting bolt and a pivot bolt, and the accessory is moved on the belt by means of a belt bracket. In the Type 3 serpentine belt, the tension of the belt is only adjusted by rotating the idler pulley adjusting bolt. Once the bolts have been loosened the component can be shifted off the engine to tighten the belt or towards the engine to loosen it by which point the tension can be checked and the bolts clamped once the desired tension has been obtained. The accessory might need adjustment with the help of a pry bar, however, one should take care to ensure not to hinder any part of it.