×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

Genuine Mazda Tribute Brake Master Cylinder

- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

8 Brake Master Cylinders found

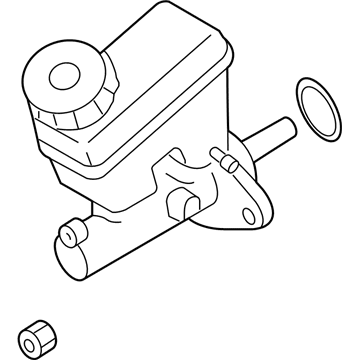

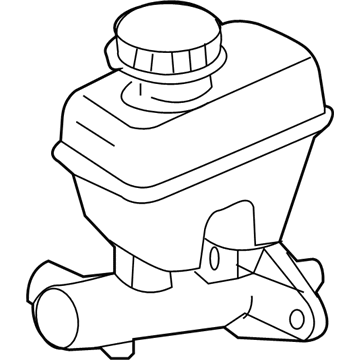

Mazda Tribute Master Cylinder Part Number: ZZC5-43-990

$173.03 MSRP: $230.75You Save: $57.72 (26%)Mazda Tribute Master Cylinder Part Number: EC01-43-400D

Mazda Tribute Master Cylinder Part Number: ZZC1-43-990A

Mazda Tribute Master Cylinder Part Number: ZZC2-43-990A

Mazda Tribute Master Cylinder Part Number: ZZC6-43-990

Mazda Tribute Master Cylinder Part Number: ZZC7-43-990

Mazda Tribute Master Cylinder Part Number: ZZD1-43-990

Mazda Tribute Master Cylinder Part Number: ZZD2-43-990

Mazda Tribute Brake Master Cylinder

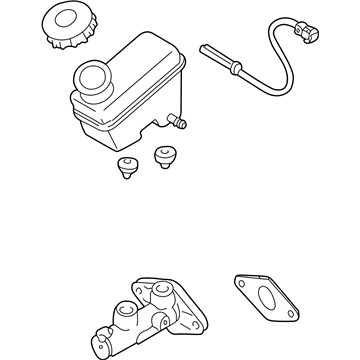

Looking for Brake Master Cylinder with proven quality? Choose OEM Brake Master Cylinder. Mazda designs and builds them to strict factory specs. Every piece goes through rigorous quality checks. You'll get parts that fit right and work like new. Shop our huge inventory of OEM Mazda Tribute parts. Enjoy the highly competitive prices online. Our site is your one-stop shop. Each genuine Tribute part includes a manufacturer's warranty. Buy with confidence. Our return policy is simple and hassle-free. In a rush? Choose expedited delivery at checkout. You'll love the streamlined experience from search to checkout to receiving your order.

Mazda Tribute Brake Master Cylinder Parts and Q&A

- Q: How to remove and install a Brake Master Cylinder on Mazda Tribute?A:Removal of the master cylinder would involve searching the engine compartment, attaching the power Brake Booster to the master cylinder and then taking out as much fluid as is possible through a syringe into the reservoir. Put rags around the fluid fittings and ready caps or plastic bags to cover the ends of the lines once they have been disconnected, and try to avoid spillage of the brake fluid that will leave paint damaged. In models since 2013, detach the battery and battery tray, and disconnection of the brake fluid remote reservoir hose with the plastic reservoir in the master cylinder. In the case of manual transaxle, disconnect the supply hose of the brake fluid reservoir with the clutch master cylinder supply hose. Fittings at the ends of the brake lines entering the master cylinder should be loosened with a flare-nut wrench to avoid the sides of the fittings appearing round, then the ends should be pulled in a little way and sealed. Unscrew the electric connector at the switch of the brakeman in the brake fluid level, unscrew the nuts that hold the master cylinder to the power booster and then gently withdraw the master cylinder out of the engine compartment. In case of the new master cylinder installation, lift off the reservoir, change the O-rings and then put the reservoir in the new one, then remember the reservoir of the former models has retaining clips whereas the new models has retaining pin. Installation before installation Bench bleed the new master cylinder by clamping the master in a vise, sealing the outlets with bleeder tubes, and filling the reservoir with the suggested brake fluid. Gradually force the pistons into the master cylinder until the air has been forced out and then remove the tubes and place plugs. Install the master cylinder with the studs in the power brake booster then screw the nuts using the fingers making sure that a new O-ring is placed in the sleeve. Install the brake line fittings into the master cylinder and position as required in order to prevent stripping threads, and then screw the mounting nuts and brake line fittings to the required torque. Add fluid and bleed the master cylinder and the brake system by standing on the brake pedal and loosening the fitting to allow the fluid and air to escape and then repeat until the fluid is devoid of bubbles. Always be prepared with rags to receive any fluid as it spoils the painted surfaces, and wash the place under the master cylinder with clean water after it gets bloody. Lastly, ensure the brake system functions well, hence reinstating back to normal service.