×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

Genuine Mazda Tribute Flywheel

Clutch Flywheel- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Flywheels found

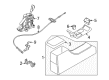

Mazda Tribute Drive Plate Part Number: FW80-19-020

$49.19 MSRP: $65.60You Save: $16.41 (26%)Mazda Tribute Drive Plate Part Number: FW60-19-020

Mazda Tribute Flywheel Part Number: L3H5-16-610

Mazda Tribute Flywheel Part Number: L501-11-500B

Mazda Tribute Flywheel

Looking for Flywheel with proven quality? Choose OEM Flywheel. Mazda designs and builds them to strict factory specs. Every piece goes through rigorous quality checks. You'll get parts that fit right and work like new. Shop our huge inventory of OEM Mazda Tribute parts. Enjoy the highly competitive prices online. Our site is your one-stop shop. Each genuine Tribute part includes a manufacturer's warranty. Buy with confidence. Our return policy is simple and hassle-free. In a rush? Choose expedited delivery at checkout. You'll love the streamlined experience from search to checkout to receiving your order.

Mazda Tribute Flywheel Parts and Q&A

- Q: How does the Flywheel function in the removal and reinstallation of a transaxle for 4 cylinder engine on Mazda Tribute?A:In order to take out the transaxle, begin by replacing such components as oil seals. In case of a manual transaxle car, take out the clutch and check its parts to have them replaced accordingly. Apply alignment marks on the flywheel/driveplate and crankshaft to ease the replacement since the holes of the bolts are not perfectly aligned. Use either a screwdriver-held by an assistant or a bit of angle-iron against the ring gear to hold the flywheel/driveplate still. Unscrew and take off all the bolts, new ones should be bought because of the strong strains they are subjected to. Take out the flywheel/driveplate carefully, without dropping it. Inspection Check driveplates cracks, and bolt hole elongation, and inspect ring gear teeth. Wipe flywheels clean to eliminate grease and oil, inspect the flywheel cracks and warpage and have clean mating surfaces. When the oil seal is leaking then replace it and re-install fly wheel and keep in mind that the engine might be of high mileage so one will change the seal. When the flywheel is off, wipe the inside of its face and the tip of the sensor, making sure that the sensor is well-fitted. Installation: When installing, use special bolts in place of flywheel/driveplate bolts provided that the engine/transaxle adapter plate is in position. Fit the flywheel/driveplate back to the marks made during removal, fit new bolts and tighten them by hand. Installation: Screw the flywheel/driveplate the same way it is removed followed by tightening the new bolts in a diagonal pattern to the required amount of torque. The other steps proceed in the opposite order of removal.