×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

Genuine Mazda 3 Brake Booster

Brake Power Booster- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

12 Brake Boosters found

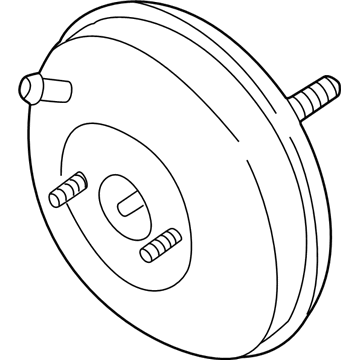

Mazda 3 Booster Part Number: BDYS-43-80ZB

$120.61 MSRP: $160.84You Save: $40.23 (26%)Ships in 1-2 Business DaysMazda 3 Booster Part Number: BCYA-43-80ZC

$164.98 MSRP: $220.01You Save: $55.03 (26%)Ships in 1-2 Business DaysMazda 3 Booster Part Number: BJY3-43-80Z

$168.51 MSRP: $224.73You Save: $56.22 (26%)Ships in 1-2 Business DaysMazda 3 Brake Booster Part Number: BPYL-43-80ZE

$262.56 MSRP: $350.16You Save: $87.60 (26%)Ships in 1-2 Business DaysMazda 3 Brake Booster Part Number: BBY7-43-80ZA

$295.88 MSRP: $394.59You Save: $98.71 (26%)Ships in 1-2 Business DaysMazda 3 Booster Part Number: BHY1-43-80ZA

$326.29 MSRP: $435.14You Save: $108.85 (26%)Ships in 1-2 Business DaysMazda 3 Brake Booster Part Number: BBY2-43-80ZA

$389.48 MSRP: $523.60You Save: $134.12 (26%)Ships in 1-2 Business DaysMazda 3 Brake Booster Part Number: BJY7-43-80ZA

$392.97 MSRP: $528.28You Save: $135.31 (26%)Ships in 1-2 Business DaysMazda 3 Brake Booster Part Number: B3YD4380Z

Mazda 3 Brake Booster Part Number: BAYR-43-80ZA

Mazda 3 Brake Booster Part Number: BBY5-43-80Z

Mazda 3 Brake Booster Part Number: BNYR-43-80ZD

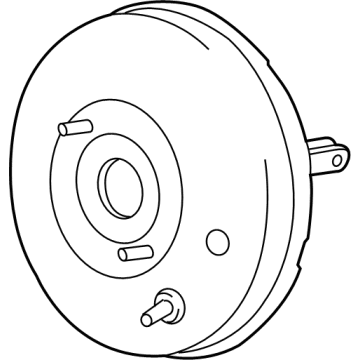

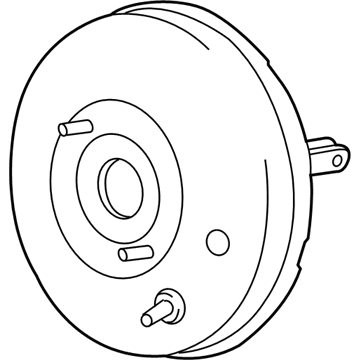

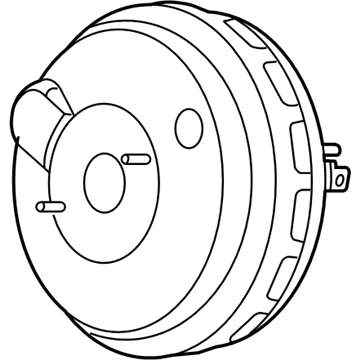

Mazda 3 Brake Booster

The Mazda 3 Brake Booster allows drivers to use less foot effort to stop the vehicle by increasing the force exerted when an operator presses the pedal through engine vacuum or hydraulic pressure. It is located between the brake pedal and the master cylinder, with the primary function of providing a bit of muscle to the push of the driver in order to tighten the grips of the brakes with a light, soft press. The majority of Mazda vehicles of this model use a vacuum booster, using low pressure from the running engine or an auxiliary pump, equalizing the vacuum on both sides of a wide diaphragm until the pedal is moved. When this pedal is pressed, an internal valve is opened, atmospheric air is admitted into the back chamber, and the pressure difference causes a power piston to move forward to power the master cylinder. Later trims are fitted with a hydraulic booster which draws high-pressure steering fluid or uses a small electric motor, which is useful when engine vacuum is weak during turbocharging or hard acceleration. The two types of booster differ in energy source but aim to achieve the same purpose, as the vacuum models rely on engine suction and the hydraulic models rely on fluid pressure, which allows designers room to experiment and drivers to feel consistency in the pedal. In the event that the engine stalls, a vacuum-based Brake Booster provides only several assisted stops, whereas a hydraulic Brake Booster can continue to provide assistance until its stored fluid pressure is depleted, helping Mazda drivers maintain confidence even when driving the sporty Mazda 3 compact.

Looking for Brake Booster with proven quality? Choose OEM Brake Booster. Mazda designs and builds them to strict factory specs. Every piece goes through rigorous quality checks. You'll get parts that fit right and work like new. Shop our huge inventory of OEM Mazda 3 parts. Enjoy the highly competitive prices online. Our site is your one-stop shop. Each genuine 3 part includes a manufacturer's warranty. Buy with confidence. Our return policy is simple and hassle-free. In a rush? Choose expedited delivery at checkout. You'll love the streamlined experience from search to checkout to receiving your order.

Mazda 3 Brake Booster Parts and Q&A

- Q: How to conduct an operating and airtightness check on a brake booster on Mazda 3?A:To check the operation of the brake pedal press the brake pedal a few times when the engine is off so that no decrease of the distance between the pedal and the frame occurs, then start the engine, in case of the slight movement of the pedal, everything is fine. To check the airtightness, turn on the engine and shut off after one or two minutes, press the brake pedal a number of times loosely, the more the pedal sinks at the first attempt the higher is the probability of the booster being airtight. With the engine running, press the brake pedal and remove the engine with the pedal pressed; in case there is no change in the pedal reserve travel after 30 seconds with the pedal held down, the booster is airtight. Improved tools are needed to dismantle the power unit and is not normally done by the home mechanic; should an issue arise, it is suggested that a new or factory rebuilt unit should be installed. Removal Components The engine cover is removable by lifting it off the mounting posts in the middle and pulling it up at each side. This follows by prying the nuts holding the master cylinder to the booster and then one must carefully pull the master cylinder forward until it slides over the mounting studs, being careful not to bend or kink the brake lines. In 2010 and subsequent models, cut off the brake lines at the brake pipe joint of the firewall which blocks the booster, seal each end of lines and the pipe joint to avoid contamination. First and foremost disconnect the vacuum hose to the power brake booster by pushing the tab and twisting the connection to the battery and unattaching both cables and then unscrew the battery. Take the PCM off the battery tray, and do not disconnect electrical connectors, then remove the battery tray. In the instrument panel, loosen the retaining pin and the washer, and loosen the pushrod on the top of the brake pedal. Installation Reverse the process to remove the booster by taking off the four nuts holding the booster to the firewall, and then carefully raise the booster unit out of the engine compartment. To fit, insert the booster into place and screw the retaining nuts to the recommended torque and join the pushrod to the brake pedal. In case the gasket of the booster-to-firewall is damaged, a new gasket would have to be used. Install the master cylinder and reconnect the brake lines in case they had been removed, and reconnect the vacuum hose. Fill the master cylinder reservoir up with fluid and bleed the master cylinder and the brake system. Lastly, check the functionality of the braking system then subject the vehicle to regular use.

Related Mazda 3 Parts

Browse by Year

2024 Brake Booster 2023 Brake Booster 2022 Brake Booster 2021 Brake Booster 2020 Brake Booster 2019 Brake Booster 2018 Brake Booster 2017 Brake Booster 2016 Brake Booster 2015 Brake Booster 2014 Brake Booster 2013 Brake Booster 2012 Brake Booster 2011 Brake Booster 2010 Brake Booster 2009 Brake Booster 2008 Brake Booster 2007 Brake Booster 2006 Brake Booster 2005 Brake Booster 2004 Brake Booster