×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

Genuine Mazda MPV Differential Seal

- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

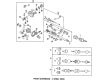

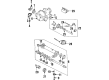

4 Differential Seals found

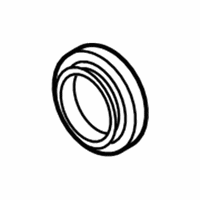

Mazda MPV Oil Seal Part Number: M0A7-27-238A

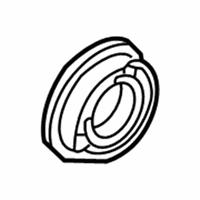

$16.64 MSRP: $22.19You Save: $5.55 (26%)Ships in 1-2 Business DaysMazda MPV Pinion Seal Part Number: R001-27-165

$21.01 MSRP: $28.02You Save: $7.01 (26%)Ships in 1-2 Business DaysMazda MPV Pinion Seal Part Number: M0A3-27-165

$10.83 MSRP: $14.44You Save: $3.61 (25%)Ships in 1-2 Business DaysMazda MPV Oil Seal Part Number: F401-17-131A

$12.11 MSRP: $16.15You Save: $4.04 (26%)Ships in 1-2 Business Days

Mazda MPV Differential Seal

Looking for Differential Seal with proven quality? Choose OEM Differential Seal. Mazda designs and builds them to strict factory specs. Every piece goes through rigorous quality checks. You'll get parts that fit right and work like new. Shop our huge inventory of OEM Mazda MPV parts. Enjoy the highly competitive prices online. Our site is your one-stop shop. Each genuine MPV part includes a manufacturer's warranty. Buy with confidence. Our return policy is simple and hassle-free. In a rush? Choose expedited delivery at checkout. You'll love the streamlined experience from search to checkout to receiving your order.

Mazda MPV Differential Seal Parts and Q&A

- Q: How to check and fill the lubricant level in a Differential Seal and Transfer Case on Mazda MPV?A:The transfer case has check and fill plugs on the sides that should be taken off to measure the level of lubricant. When lifting the vehicle to reach the plugs, make sure that it is well supported with jackstands, never at any time should it be supported solely by a jack. To test the level of lubricant, take out the level plug and feel in the inside of the housing with your little finger, the lubricant bottom of the plug hole should be at or very close to the bottom. When the level is low then take out the upper plug and pour in the suggested lubricant with the help of a syringe or squeeze bottle. Once lubricant is added then insert the plugs, screw them in, and inspect them before driving several miles.

- Q: How to address pinion shaft oil seal failure and repair in Differential Seals for both front and rear differentials on Mazda MPV?A:The process below is used in the front differential and the rear differentials. Failing of a pinion shaft oil seal results in the lubricant used in the differential gear leaking into the Driveshaft yoke or flange past the seal and the seal can be changed without the need to remove or disassemble the differential. The first step is to lift the car and place it on jackstands. Drain the differential lubricant and, when the drain is fully done, install the drain plug and tighten it. Unattach the driveshaft to the pinion shaft yoke and hold it out of the way with a piece of wire. With an inch pound torque wrench, have the amount of torque to move the pinion shaft in the backlash and document this value to be used in the set up to preload the pinion shaft. Clamp the companion flange in place with a large screwdriver or prybar, and then loosen the companion flange nut which indicates the alignment of the pinion shaft with the companion flange. Take the companion flange out of the pinion shaft using a two-jaw puller. The seal is carefully removed out of the differential, perhaps by means of a hammer and a punch, but the splines and threads of the pinion shaft must not be interfered with. Keep the new seal lip greasy with multipurpose grease or differential lubricant and then install it in place carefully, either by using a hammer and a seal driver, a large socket, or a short piece of pipe of the correct diameter to force the seal into place. Clean the sealing lip contact surface of the companion flange, rub a thin film of multipurpose grease to the seal contact surface and the shaft splines, and slide the companion flange onto the shaft, so that the match marks are aligned. Apply multipurpose grease to the threads of the pinion shaft, fit a new nut and loosely screw the nut to the first torque without rotating the flange. Rotate the companion flange a number of times to fit the bearing. With an inch-pound torque wrench, time the torque needed to rotate the pinion shaft in its backlash; the desired preload is the one that was measured above multiplied by five inch-pounds. In case the preload is not as desired, continue to tighten the nut in small steps until the desired preload is achieved. In case of reaching the maximum torque on the pinion shaft nut before it reaches the desired preload, the bearing spacer should be substituted at a repair shop. The pinion nut should not be backed-off to decrease the preload. When the preload has been adjusted correctly, attach the driveshaft to the companion flange. Add filler with the suggested lubricant, rock the vehicle to the floor, and drive it, and observe around the companion flange, whether there is leakage or not.