×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

Genuine Mazda MPV Flywheel

Clutch Flywheel- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Flywheels found

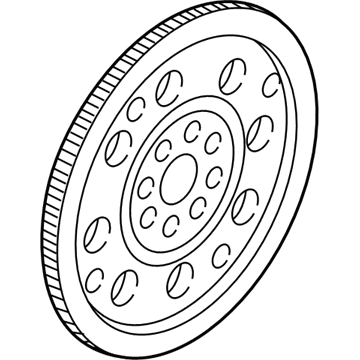

Mazda MPV Flywheel Part Number: GY01-19-020B

$142.99 MSRP: $190.69You Save: $47.70 (26%)Ships in 1-2 Business DaysMazda MPV Flywheel Part Number: FP01-19-020A

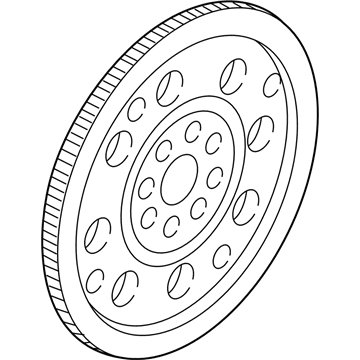

Mazda MPV Flywheel Part Number: G601-11-500B

Mazda MPV Flywheel

Looking for Flywheel with proven quality? Choose OEM Flywheel. Mazda designs and builds them to strict factory specs. Every piece goes through rigorous quality checks. You'll get parts that fit right and work like new. Shop our huge inventory of OEM Mazda MPV parts. Enjoy the highly competitive prices online. Our site is your one-stop shop. Each genuine MPV part includes a manufacturer's warranty. Buy with confidence. Our return policy is simple and hassle-free. In a rush? Choose expedited delivery at checkout. You'll love the streamlined experience from search to checkout to receiving your order.

Mazda MPV Flywheel Parts and Q&A

- Q: How to remove and reinstall a transmission and flywheel/driveplate for four-cylinder engine on Mazda MPV?A:In order to eliminate the transmission, raise the vehicle and place it on jackstands first and remove the transmission. Second, lift off the pressure plate and the clutch disc where you have a chance to inspect or replace the clutch parts and pilot bearing. Mark alignment marks on the flywheel/driveplate and crankshaft to identify how the two related before removal so that they can be aligned correctly upon reinstallation. Take out the bolts holding the flywheel/driveplate to the crankshaft, on automatic transmission models place a punch through one of the holes to make the driveplate not come round as the bolts are unwound. In the case of crankshaft rotation, disengage the starter and force a screwdriver into the ring gear teeth in cases of the manual transmission and a long punch in case of the automatic transmission. Once the flywheel/driveplate has been removed, support it, removing the final bolt and wiping it to get rid of grease and oil, checking it against cracks, rivet grooves, burnt spots, and score lines, and light scoring can be removed with emery cloth. Linear check Visual inspection of cracked and broken ring gear teeth, and flat surface lay of flywheel to check warpage. Clean and wash up the mating surfaces of flywheel/driveplate and crankshaft before re-assembling but replace crankshaft rear seal that is already leaking. To install, place the flywheel/driveplate against the crankshaft aligning the marks left during removal and make sure it is correctly installed with the aid of alignment dowels or staggered bolt holes where necessary. Put thread locking compound on the threads of the bolts and then tighten them to the required torque value, and then reverse the procedure used to remove them.