×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

Genuine Mazda MX-5 Miata Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Cylinder Heads found

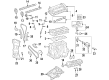

Mazda MX-5 Miata Cylinder Head Part Number: LFE2-10-090K

$1055.48 MSRP: $1442.21You Save: $386.73 (27%)Ships in 1-2 Business DaysMazda MX-5 Miata Cylinder Head Part Number: PEES-10-100A

$1639.55 MSRP: $2240.27You Save: $600.72 (27%)Ships in 1-2 Business DaysMazda MX-5 Miata Cylinder Head Part Number: PE31-10-100A

$1556.40 MSRP: $2126.66You Save: $570.26 (27%)Ships in 1-2 Business DaysMazda MX-5 Miata Cylinder Head Part Number: LF9G-10-090A

$1885.94 MSRP: $2576.93You Save: $690.99 (27%)Ships in 1-2 Business Days

Mazda MX-5 Miata Cylinder Head

Looking for Cylinder Head with proven quality? Choose OEM Cylinder Head. Mazda designs and builds them to strict factory specs. Every piece goes through rigorous quality checks. You'll get parts that fit right and work like new. Shop our huge inventory of OEM Mazda MX-5 Miata parts. Enjoy the highly competitive prices online. Our site is your one-stop shop. Each genuine MX-5 Miata part includes a manufacturer's warranty. Buy with confidence. Our return policy is simple and hassle-free. In a rush? Choose expedited delivery at checkout. You'll love the streamlined experience from search to checkout to receiving your order.

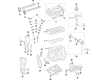

Mazda MX-5 Miata Cylinder Head Parts and Q&A

- Q: How to remove and reinstall a cylinder head on Mazda MX-5 Miata?A:Removing the cylinder head begins with the disconnection of the negative cable of the battery and empty the engine coolant and oil after which the oil filter is removed. Then remove air intake duct assembly, spark plugs, throttle valve cable, accelerator cable and other hoses, label them with label to reload them. Loose all electrical connector and the wiring harness connection to the cylinder head and label them. Disassemble bypass water through bolts, water pump pulley, drive belt, fuel rail, injectors, Intake Manifold, exhaust manifold, Valve Cover and timing belt or chain. Installation Unbolt and open the power steering pump without disconnection of hoses, label and detach all remaining components which may hinder removal of cylinder head, then loosen the bolts of the cylinder head by 1/4-turn increments until hand removal becomes possible. Take off the cylinder head of the engine block by lifting it up, if necessary with pry, and unattaching all exterior items to clean and examine. To fit, the block and the cylinder head must have clean mating surfaces and it is best to clean the surfaces with a gasket scraper and solvent to remove any grease. Confirm that the mating surfaces are not damaged and clean the threads on the head bolts where necessary, replacing damaged ones with OEM parts. Install all the components that have been taken off the head, install the new gasket and securely place the head on the block. Coat threads of head bolts with clean engine oil, screw them in by hand and subsequently screw them in the correct order to the correct tightness. The rest of the steps should be done in order of reversal, replace the cooling system, change the oil filter, fill the engine, test run the vehicle on the road to check on leaks, adjust the ignition timing, and road test the automobile, and monitor the coolant level regularly within the first several hundred miles to make sure that there is no leakage.