×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

Genuine Mazda Tribute Shock Absorber

Suspension Shock Absorber- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Shock Absorbers found

Mazda Tribute Shock Part Number: ZZ24-28-700

$8.20 MSRP: $10.77You Save: $2.57 (24%)Ships in 1-2 Business DaysMazda Tribute Shock Part Number: ZZC2-28-700

$41.93 MSRP: $55.91You Save: $13.98 (25%)Mazda Tribute Shock Part Number: ZZD3-28-700

$38.03 MSRP: $50.71You Save: $12.68 (25%)Ships in 1-2 Business DaysMazda Tribute Shock Part Number: EC05-28-700L

Mazda Tribute Shock Part Number: EG02-28-700F

Mazda Tribute Shock Part Number: ZZC3-28-700

Mazda Tribute Shock Absorber

Looking for Shock Absorber with proven quality? Choose OEM Shock Absorber. Mazda designs and builds them to strict factory specs. Every piece goes through rigorous quality checks. You'll get parts that fit right and work like new. Shop our huge inventory of OEM Mazda Tribute parts. Enjoy the highly competitive prices online. Our site is your one-stop shop. Each genuine Tribute part includes a manufacturer's warranty. Buy with confidence. Our return policy is simple and hassle-free. In a rush? Choose expedited delivery at checkout. You'll love the streamlined experience from search to checkout to receiving your order.

Mazda Tribute Shock Absorber Parts and Q&A

- Q: What actions are necessary when Coil Springs and Shock Absorber show signs of wear on Mazda Tribute?A:When the front suspension struts display any wear conditions (such as leaking fluid, damping loss, or sagging and cracked Coil Springs) then they can be disassembled and overhauled accordingly and faulty struts need replacement whereas springs and other components can be replaced individually. Both sides have to be replaced to ensure that the balance between the properties is maintained. After the strut is out of the car, clear off all the foreign matter and you should fit it in the vise. Install the coil spring compressor tools in place and push the spring up until all the tension is out of the upper mount. Using an Allen key, loose the strut piston rod and using a box-end wrench, loosen the retaining nut of the thrust bearing then withdraw the top mounting, thrust bearing, upper spring seat and spring and the boot and bump stop. In case a new spring is to be inserted, the old spring must be removed carefully out of the compressor; in case of a reuse, the spring may be left under compression. Once the strut assembly is disassembled, inspect every part of the assembly in terms of wear and damage, and also ensure the bearing is running smoothly and that the parts are in place accordingly. Look at the strut to see whether it is leaking fluid, examine the piston rod to see whether it is pitted and examine the strut body whether it has been damaged. Check the functioning of the strut by operating the piston in both full and short strokes and make sure the resistance is smooth and continuous; rough or irregular resistance denotes that it requires replacement. Reassembly consists of repeating the dismantling process, making sure the coil springs are fitted with the paint mark at the bottom, that the coil spring ends are carefully placed in the upper and lower seats, before the release of the compressor, and to confirm that the bearing is properly fitted to the piston rod seat, and the thrust bearing retaining nut is tightened to the required torque.

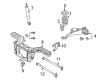

- Q: How to remove and install a rear shock absorber on Mazda Tribute?A:Unscrew the wheel lug nuts, elevate the car and hold it firmly on jackstands with the front wheels blocked to ensure that it does not roll and then remove the wheel. Placing a floor jack to hold the outer end of the lower arm, elevate it slightly to take off pressure on the shock absorber lower mount. To gain access to the shock absorber upper mounting nut, 2012 and earlier models, remove the rear quarter trim panel, then the nuts, upper retainer, bushing and lower retainer, inside the vehicle. To remove access to upper shock absorber bolts in the fenderwell, use an extension and socket to access the inner bolts. In 2012 and earlier models, loosen the lower mounting nut of the shock absorber and disassemble the shock absorber tangling it off the mounting pin, keeping track of the retainers. On later models (2013 and above) and in order to replace the shock absorber, remove the lower mounting block bolt to dislodge the shock off the rear knuckle, then unscrew the nut off the damper rod and slide the mount off, fitting it to the new shock absorber and screwing the nut firmly. Installation is the opposite of the removal process and should make sure that the fasteners of the mounting are tightened to the required torque and the rear suspension raised with the floor jack to approximate normal ride height and then use the lower mounting nut or bolt before tightening.