×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

Genuine Mazda MX-5 Miata Brake Booster

Brake Power Booster- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Brake Boosters found

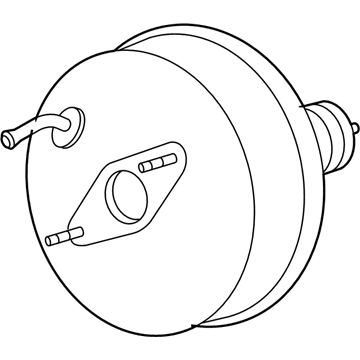

Mazda MX-5 Miata Brake Booster Part Number: NFY7-43-80ZA

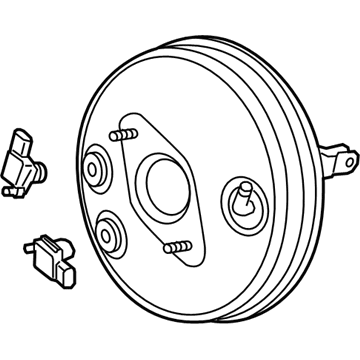

$184.80 MSRP: $246.44You Save: $61.64 (26%)Ships in 1-2 Business DaysMazda MX-5 Miata Brake Booster Part Number: NAYJ-43-80Z

$210.95 MSRP: $281.33You Save: $70.38 (26%)Ships in 1-2 Business Days

Mazda MX-5 Miata Brake Booster

Looking for Brake Booster with proven quality? Choose OEM Brake Booster. Mazda designs and builds them to strict factory specs. Every piece goes through rigorous quality checks. You'll get parts that fit right and work like new. Shop our huge inventory of OEM Mazda MX-5 Miata parts. Enjoy the highly competitive prices online. Our site is your one-stop shop. Each genuine MX-5 Miata part includes a manufacturer's warranty. Buy with confidence. Our return policy is simple and hassle-free. In a rush? Choose expedited delivery at checkout. You'll love the streamlined experience from search to checkout to receiving your order.

Mazda MX-5 Miata Brake Booster Parts and Q&A

- Q: How to perform an operating check and airtightness check on a power brake booster on Mazda MX-5 Miata?A:In order to do an operating check, press the brake pedal multiple times when the engine is turned off and be sure that no adjustment of the pedal reserve distance occurred. Then, switch on the engine with the pedal; a small drop shows that everything is alright. To check airtightness, fire up the engine and switch it off after a minute or two; press the brake pedal gradually several times; with less resistance to each press the booster is airtight. When the engine is running, press the pedal and then switch off the engine, after 30 seconds, unless the travel of the pedal has decreased, the booster is airtight. In case airtightness check is failed, check or replace the power brake booster vacuum hose or check valve and recheck. The units of power brake booster are not to be disassembled because of the requirement of special tools; they are to be replaced with new or rebuilt ones. Last but not least: Discontinue the vacuum hone/check valve to the engine slowly to avoid damage. Pull out the Brake Master Cylinder, steering column lower finish panel and the return spring of the pedal. Find the pushrod clevis that joins the booster with the brake pedal and pull off the retaining clip/clevis pin and the booster off the firewall by unscrewing the four mounting nuts. Press the booster out straight without losing the gasket. To install, reverse the process of removal, screwing the booster mounting nuts accordingly and a fresh clevis retaining clip where required. Make sure that when fitting the vacuum hose/check valve, the arrows of the hose are facing the engine. When changing the power brake booster unit, measure and reposition the distance between the master cylinder piston and the pushrod of which only non-ABS models can be correctly adapted, and the work should be performed using special tools used to adjust the parameters in ABS-equipped models. Install the master cylinder, Brake Hoses, adjust the brake pedal height and free play and bleed the brake system.

Related Mazda MX-5 Miata Parts

Browse by Year

2023 Brake Booster 2022 Brake Booster 2021 Brake Booster 2020 Brake Booster 2019 Brake Booster 2018 Brake Booster 2017 Brake Booster 2016 Brake Booster 2015 Brake Booster 2014 Brake Booster 2013 Brake Booster 2012 Brake Booster 2011 Brake Booster 2010 Brake Booster 2009 Brake Booster 2008 Brake Booster 2007 Brake Booster 2006 Brake Booster