×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

Genuine Mazda Transfer Case

Speed Transfer Case- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

10 Transfer Cases found

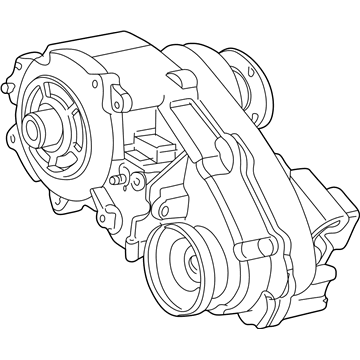

Mazda Transfer Case Part Number: CN01-27-500A

$945.05 MSRP: $1291.31You Save: $346.26 (27%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Transfer; Transfer Case

- Replaces: CN01-27-500

Mazda Transfer Case Part Number: AW21-27-500R-9U

$1083.02 MSRP: $1479.83You Save: $396.81 (27%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Transfer

- Replaces: AW21-27-500K, AW21-27-500N, AW21-27-500N-9U, AW21-27-500R, AW21-27-500P-9U, AW21-27-500K-9U, AW21-27-500P

Mazda Transfer Case Part Number: KN03-27-500

$1456.53 MSRP: $1990.19You Save: $533.66 (27%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Transfer; Transfer Case

- Replaced by: KN03-27-500A

Mazda Transfer Case Part Number: KN01-27-500A

$1624.78 MSRP: $2220.10You Save: $595.32 (27%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Transfer; Transfer Case

- Replaces: KN01-27-500

Mazda Case Part Number: 1F71-17-910B

$355.65 MSRP: $466.83You Save: $111.18 (24%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Case, Transfer; Transfer Case

Mazda Transfer Case Part Number: LN03-27-500M

Product Specifications- Other Name: Transfer

- Replaces: LN03-27-500A, LN03-27-500D, LN03-27-500L, LN03-27-500H, LN03-27-500B, LN03-27-500G, LN03-27-500J

Mazda Case Part Number: 1FAB-17-910A

Product Specifications- Other Name: Case, Transfer; Case

Mazda Transfer Case Part Number: LN11-27-500A

Product Specifications- Other Name: Transfer

Mazda Transfer Case Part Number: ZZ2A-27-500A

Product Specifications- Other Name: Transfer

Mazda Transfer Case Part Number: ZZC0-27-500A

Product Specifications- Other Name: Transfer

Mazda Transfer Case

Four-wheel drive (4WD) and all-wheel drive (AWD) cars exclusively contain a transfer case, which is a specialized gearbox. It has the critical function of channeling engine power to both the front and rear axles. The gears in this box are kept cool and moving smoothly by lubricating fluid. Dirty fluid in your Mazda transfer case or trouble changing gears should signal to you that your vehicle's transfer case needs a prompt replacement for better road performance.

Whenever you need replacements, opt for genuine Mazda Transfer Cases. Because they meet the manufacturer's criteria, it guarantees that replacements fit perfectly. Thus, these make better choices for people who care about driving. Why should you shop at MazdaPartsNow.com? We sell genuine Mazda Transfer Cases. In our online catalog, there is a wide range of different parts. These are delivered directly from authorized Mazda dealers only so that customers can be sure of their security throughout any transaction while using our website. Furthermore, you can also quickly search for OEM parts you want because of our user-friendly site navigation. Choose us for a genuine Mazda Transfer Case that keeps your car running like new.

Mazda Transfer Case Parts and Q&A

- Q: How to remove and install the transfer case on Mazda Tribute?A:On 2004 and earlier four-cylinder models, loosen the wheel lug nuts on the right front, raise the front-end of the car and place it safely on jackstands and then remove the wheel. Unscrew the front section of the driveshaft, and hang it using wire, then dismantle the right driveaxle and intermediate shaft. The next step would be to take out the four bolts holding the crossmember together and then extract it out, then extract the upper two mounting nuts and two lower mounting bolts on the right side of the transfer case to disjoin it with the vehicle. To install them, follow these procedures in reverse, be sure to put a new O-ring seal in place, tighten the driveshaft and transfer case bolts to the proper recommended torque, pour more transfer case fluid in, and lastly put in the wheel lug nuts. In case of V6, the procedure begins by removing the wheel cover or the hub cap, loosening the hub nut, and the wheel lug nuts. Once the vehicle has been lifted and supported, loosen the front section of the driveshaft and then suspend it, then do the same to the right driveaxle, intermediate shaft, crossover pipe of the exhaust system and rear exhaust manifold. Take off crossmember and alternator then take off the transfer case bracket off the engine block and take off the transfer case mounting bolts. In 2005 to 2008 models, lift up the vehicle, empty the transfer case fluid, take out the driveshaft, and crossmember brace. On manual transaxle models, loosen 2 mounting bolts and nuts of transaxle and pull the transfer case forward off the rear stud, discarding the big O-ring. In automatic transaxle, delete the right driveaxle, intermediate shaft, interfering exhaust manifold, transfer case heat shield and mounting bracket and delete the vent tube and transfer case mounting bolts. In 2009 and subsequent models, lift the vehicle, jack it up, take off the under-vehicle splash shield, empty the transfer case fluid and take off the driveshaft. To 2012 and earlier, dismantle the crossmember brace, right driveaxle, intermediate shaft, interfering exhaust manifold, turbocharger outlet pipe, heat shield, and two exhaust bracket nuts then dismantle the transfer case support bracket and vent tube then loosen the transfer case mounting bolts. Installation is the opposite of the removal and it will make sure that a new O-ring seal is laid, that exhaust system and driveshaft fasteners are tightened to the specified torque, that transfer case is filled with the correct lubricant, and that the wheel lug nuts are tight.