×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

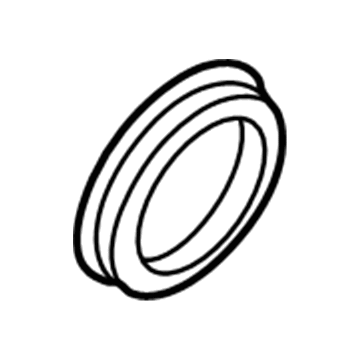

Genuine Mazda Axle Shaft Seal

CV Axle Seal- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

93 Axle Shaft Seals found

Mazda Dust Seal Part Number: G003-25-744A

$8.79 MSRP: $11.72You Save: $2.93 (25%)Ships in 1-2 Business DaysProduct Specifications- Position: Left

- Replaces: G003-25-744

Mazda Dust Seal Part Number: G560-25-744

$9.84 MSRP: $13.12You Save: $3.28 (25%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Outer Seal

- Position: Left

Mazda Inner Seal Part Number: GA67-25-744

$10.04 MSRP: $13.39You Save: $3.35 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Seal, Dust; Bracket Seal

- Position: Left

Mazda Axle Seals Part Number: MA02-27-238A

$10.41 MSRP: $13.88You Save: $3.47 (25%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Seal, Oil; Axle Seal

- Replaces: MA02-27-238

Mazda Axle Seals Part Number: F003-27-238C

$10.61 MSRP: $14.15You Save: $3.54 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Seal, Oil; Axle Seal

- Replaces: F001-27-238, F003-27-238, F003-27-238A, F003-27-238B

Mazda Output Shaft Seal Part Number: P016-27-238

$10.96 MSRP: $14.63You Save: $3.67 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Seal, Oil; Axle Seal

Mazda Seal Part Number: G003-25-742A

$11.38 MSRP: $15.17You Save: $3.79 (25%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Seal, Dust; Inner Seal, Seal

- Position: Right

- Replaces: G003-25-742

Mazda Dust Seal Part Number: G560-25-742

$11.29 MSRP: $15.05You Save: $3.76 (25%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Seal, Dust

- Position: Right

Mazda Seal Kit Part Number: VAY0-33-26Z

$12.90 MSRP: $17.20You Save: $4.30 (25%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Seal & Boot Set, Caliper-Front; Seal Kit

Mazda Dust Seal Part Number: G569-25-742

$13.06 MSRP: $17.43You Save: $4.37 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Seal, Dust; Dust Seal, Outer Seal

- Position: Inner

Mazda Seal Part Number: G304-33-065

$13.66 MSRP: $18.22You Save: $4.56 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Oil Seal

Mazda Outer Seal Part Number: GA70-25-742

$15.03 MSRP: $20.04You Save: $5.01 (25%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Seal, Dust

- Position: Outer

- Replaces: GA52-25-742

Mazda Pinion Seal Part Number: M005-27-165

$15.69 MSRP: $20.91You Save: $5.22 (25%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Oil Seal

Mazda Oil Seal Part Number: M0A7-27-238A

$16.64 MSRP: $22.19You Save: $5.55 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Seal, Oil; Axle Seal, Oil Seal

- Replaces: M0A7-27-238

Mazda Seal Kit Part Number: TKY8-26-46Z

$18.05 MSRP: $24.08You Save: $6.03 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Seal & Boot Set, Caliper-Rear; Caliper Seal Kit

Mazda Dust Seal Part Number: C2A1-25-742

$18.30 MSRP: $24.40You Save: $6.10 (25%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Seal, Dust; Outer Seal

Mazda Outer Seal Part Number: GA67-25-742

$18.34 MSRP: $24.46You Save: $6.12 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Seal, Dust

- Position: Outer

- Replaces: GG30-25-742

Mazda Inner Seal Part Number: GA68-25-744

$20.44 MSRP: $27.26You Save: $6.82 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Seal, Dust

- Position: Inner

Mazda Pinion Seal Part Number: R001-27-165

$21.01 MSRP: $28.02You Save: $7.01 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Oil Seal; Front Seal

- Replaces: P017-27-165

Mazda Hub Seals Part Number: B001-33-065A

Product Specifications- Other Name: Oil Seal; Hub Seal, Wheel Bearing Oil Seal

| Page 1 of 5 |Next >

1-20 of 93 Results

Mazda Axle Shaft Seal

Every part of the car is important. Your vehicle's performance will be compromised if something goes wrong with the Mazda Axle Shaft Seal. Therefore, for your smooth driving and safety, you need regular checks and timely replacements. Whenever you need replacements, opt for genuine Mazda Axle Shaft Seals. Because they meet the manufacturer's criteria, it guarantees that replacements fit perfectly. Thus, these make better choices for people who care about driving. Why should you shop at MazdaPartsNow.com? We sell genuine Mazda Axle Shaft Seals. In our online catalog, there is a wide range of different parts. These are delivered directly from authorized Mazda dealers only so that customers can be sure of their security throughout any transaction while using our website. Furthermore, you can also quickly search for OEM parts you want because of our user-friendly site navigation. Choose us for a genuine Mazda Axle Shaft Seal that keeps your car running like new.

Mazda Axle Shaft Seal Parts and Q&A

- Q: How to perform removals and installations for rear Axle Shaft, Axle Shaft Seal and Wheel Bearing on Mazda B2200?A:Removals and installations To carry out removals and installations, you should put the jackstands in place to support the rear end up and then remove the wheel and brake drum then the brake shoes and parking brake cable retainer. Disassemble and disconnect the brake lines at the wheel cylinders followed by removing the bolts which hold the backing plate/bearing housing and sliding the axle shaft out of the axle housing without damaging the oil seal. In case of damage of the seal, a slide hammer and adapter should be used to replace it. Take out two overlapping plate bolts at right angles to each other, grind the bearing retaining collar until near 5mm remains, and snap the collar off with a chisel, taking care not to spoil the shaft. A press or a puller is used to remove the hub and bearing assembly, the bearing and seal are removed off the hub with a drift being tapped on the race. Inspect all components of wear or damage and replace both races where one is replaced and replace the bearing and seals as a set. To install, the outer race is pressed using an arbor press and the inner race forced into place. Wipe the hub with lithium-based wheel bearing grease, pound a new oil seal into the axle bearing-housing, and a new spacer into the shaft with the greater plain surface side up. Replacement of the seal in the hub, pack bearings grease-filled, and forcefully fit the assembly (hub and bearing) on to the shaft. Install the new collar onto the shaft with the recommended press pressure of between 9,240-13,420 lb. by observing that the bearing plays with a dial indicator and if needed, Shims are applied to adjust the bearing plays. Install the other sleeve, and torque the backing plate bolts and re-check the play. Lastly, put in the brake drums and wheels and bleed the brake system. In the case of the Navajo model, the negative battery connection should be disconnected, the vehicle raised, the rear wheels and brakes drums should be taken off, and the lubricant in the rear axle should be drained. On axles other than 3.73:1 or 4.10:1 ratios, loosen the differential pinion shaft lock bolt, and pinion shaft, push the axle shafts towards the center to dislodge the C-lockwasher, and take out the axle shafts. To remove the pinion shaft lock bolt in case of 3.73:1 and 4.10:1 ratios, push the pinion shaft out of the slot and then remove C-lockwasher and the axle shaft. Removal of bearing and seal To remove bearing and seal, use a bearing and seal remover with a slide hammer. Installation To install, lubricate the new bearing and press in the housing bore, rub lubricant between the lips of the axle shaft seal, and fit a new axle shaft seal. Slide the axle shaft into the housing taking great care to avoid breaking the oil seal, and connect the splines to the side gear. Install the C-lockwasher, and extract the shaft outboard and install the differential pinon shaft over the case and tighten the lock bolt. Wipe down the area of gasket mountings, put silicone sealant, cover and screw in the bolts. Add lubricant until it is 14 in. below the filler hole and put in filler plug.

- Q: How to remove and install the Axle Shaft, Axle Shaft Seal and Wheel Bearing on Mazda B2000?A:To change and fit the axle parts of the 1972 to 1984 models, the first thing to do is to raise and put the rear portion on jackstands and then carry out the removal of the wheels and the brake drums and then the brake shoes and the parking brake cable retainer. Break and disconnect the brake lines following the wheel cylinders and then loosen bolts of the backing plate and bearing housing and slide axle shaft out of the axle housing. Take out and destroy the oil seal, bend the tabs of the lockwasher, and remove the nut and lockwasher on the axle shaft. Take off the bearing and race of the shaft, and the spacer, and outer seal of the bearing housing, and the gasket of the baffle. Install new seals and a new gasket in that reverse order, provisionally clamping the bearing/backing plate bolts to 16 ft. lbs. without the brake shoes or drum. Check axle shaft endplay measurement by dial indicator; 0.05-0.15mm when one of the two shafts has been removed and 0.66-0.84mm after replacement of the first shaft. Tighten endplay where required and screw up the bearing retainer/backing plate bolts to 40-50 ft. lbs. With models dating 1986 to 1989, lifting and propping the rear end on jackstands, dismounting the wheel and brake drum, and then dismounting the brake shoes and parking brake cable retainer. Disassemble and disconnect brake lines after which the bolts that hold the backing plate and bearing housing are removed slide the axle shaft out of the axle housing being careful not to fail the oil seal. In case it has a broken seal, one has to replace it with a slide hammer and an adapter. Eliminate two support plate bolts at a right angle, cut the bearing retaining collar diagonally until approximately 5mm is left and snap the collar in a chisel. Take the hub and bearing assembly out with press or puller, and then tap the race off the hub with a drift, take the bearing out and seal out of the hub. Inspect all its components, including checking for wear or damage, and assembling the outer race by an arbor press when replacing either of the races, and force the inner race into the axle housing. Fill the hub with lithium impact bearing grease, punch a fresh oil seal into the axle housing and screw on a fresh spacer on the shaft with the broader flat surface upward. Install a new hub seal, grease the bearing and press the bearing and hub assembly onto the shaft and press the new collar onto the shaft with an applied pressure. Install a single shaft in the housing, with bearing play being checked in case of a single shaft having been serviced and bolts on the backing plate tightened to 80 ft. lbs. to place a dial indicator on the backing plate to measure axial play and ensure that it does not exceed the standard requirements. Install the rest of the shaft, tighten the backing plate bolts, check the play and use shims to adjust the play where needed and then install the brake drums and the brake wheels and bleed the brake system.

Related Mazda Parts

Browse by Model

2 Axle Shaft Seal 3 Axle Shaft Seal 323 Axle Shaft Seal 5 Axle Shaft Seal 6 Axle Shaft Seal 626 Axle Shaft Seal 929 Axle Shaft Seal B2000 Axle Shaft Seal B2200 Axle Shaft Seal B2300 Axle Shaft Seal B2500 Axle Shaft Seal B2600 Axle Shaft Seal B3000 Axle Shaft Seal B4000 Axle Shaft Seal CX-3 Axle Shaft Seal CX-30 Axle Shaft Seal CX-5 Axle Shaft Seal CX-50 Axle Shaft Seal CX-7 Axle Shaft Seal CX-9 Axle Shaft Seal GLC Axle Shaft Seal MPV Axle Shaft Seal MX-3 Axle Shaft Seal MX-5 Miata Axle Shaft Seal MX-6 Axle Shaft Seal Miata Axle Shaft Seal Millenia Axle Shaft Seal Navajo Axle Shaft Seal Protege Axle Shaft Seal Protege5 Axle Shaft Seal RX-7 Axle Shaft Seal RX-8 Axle Shaft Seal Tribute Axle Shaft Seal