×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

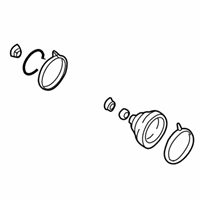

Genuine Mazda Tribute CV Joint Boot

Constant-Velocity Joint Boot- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 CV Joint Boots found

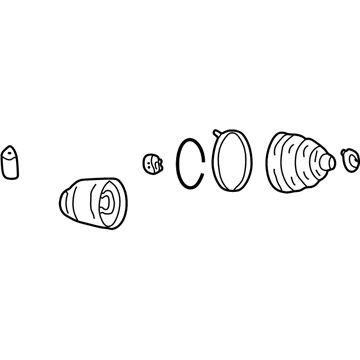

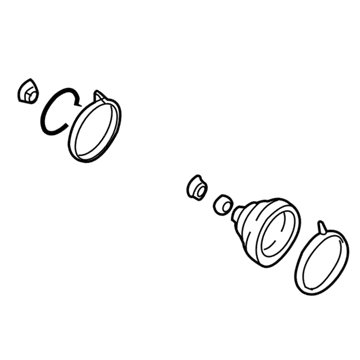

Mazda Tribute Inner Boot Part Number: GG31-22-540

$34.01 MSRP: $45.36You Save: $11.35 (26%)Ships in 1-2 Business DaysMazda Tribute Inner Boot Part Number: GG05-22-540

$37.88 MSRP: $50.51You Save: $12.63 (25%)Ships in 1-2 Business DaysMazda Tribute Inner Boot Part Number: GG36-22-540

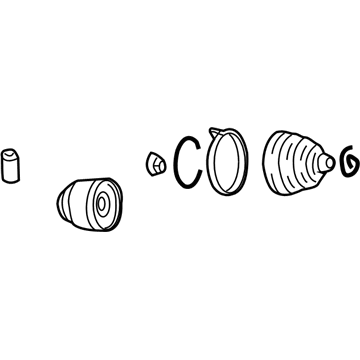

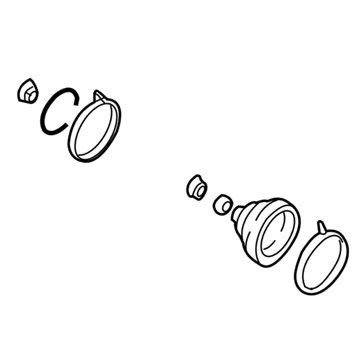

$46.18 MSRP: $61.58You Save: $15.40 (26%)Ships in 1-2 Business DaysMazda Tribute Outer Boot Part Number: GG03-22-530

$49.55 MSRP: $66.08You Save: $16.53 (26%)Ships in 1-2 Business DaysMazda Tribute Outer Boot Part Number: GG31-22-530

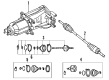

$20.74 MSRP: $27.66You Save: $6.92 (26%)Ships in 1-2 Business DaysMazda Tribute Inner Boot Part Number: GD29-22-540

$80.71 MSRP: $107.64You Save: $26.93 (26%)Ships in 1-2 Business DaysMazda Tribute Outer Boot Part Number: GD29-22-530

$100.71 MSRP: $134.31You Save: $33.60 (26%)Ships in 1-2 Business Days

Mazda Tribute CV Joint Boot

Looking for CV Joint Boot with proven quality? Choose OEM CV Joint Boot. Mazda designs and builds them to strict factory specs. Every piece goes through rigorous quality checks. You'll get parts that fit right and work like new. Shop our huge inventory of OEM Mazda Tribute parts. Enjoy the highly competitive prices online. Our site is your one-stop shop. Each genuine Tribute part includes a manufacturer's warranty. Buy with confidence. Our return policy is simple and hassle-free. In a rush? Choose expedited delivery at checkout. You'll love the streamlined experience from search to checkout to receiving your order.

Mazda Tribute CV Joint Boot Parts and Q&A

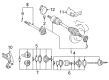

- Q: How to inspect the CV Joint Boot and other steering and suspension components for wear and damage on Mazda Tribute?A:To get a detailed illustration of the steering and suspension components, first park the vehicle and then carefully rock the steering wheel back and forth, this will illustrate whether the vehicle has worn the front wheel bearings, steering shaft universal joint or lower arm balljoint, or whether the steering gear is not adjusted correctly, or is broken. Additional indicators such as uncontrolled driving over bumpy roads, swinging around corners and binding in turning the steering wheel can be an indication of faulty steering or suspension systems. To test the shock absorbers, push down and release the vehicle at all corners, the vehicle should go back on an even stand within a few bounces, failure to do this indicates that the shock absorbers or struts are worn out and should be replaced. During this process, listen to the squeaks and noises, and examine the shocks to be sure they are not leaking fluid, the fluid leaking should be explained to be due to the shocks, and not another cause; in case of fluid leakage replace the shocks as a set. Corroborate that the shocks are firmly attached and pristine and inspect the upper mounts, surveying them to distinguish wear or damage and substituting them as a set should there be need. Lift the car using a floor jack and place it on jackstands, inspect the tires with regard to their irregular wear patterns and inflation. Check the universal joint of the steering shaft and steering gear housing to see if there is any leakage of lubricant and make sure that the dust seals and boots are in place and boot clamps are firm. Inspect steering linkage, look at tie-rod ends (check excessive motion), check loose bolts, broken components and worn rubber bushings. As an assistant rotates the steering wheel, observe any slack, chafing and binding in the steering part, and free movement. To determine wear in balljoints, a pry bar should be used to raise and lower each control arm and should there be play, the balljoint must be substituted. Check ball joint boots on damage and leaking grease, and replace damaged balljoint. At the back, check on the wearing of suspension arm bushings. CV Joint Boots are essential that keep CV joints dry of dirt and moisture that damages them, they should be washed with soap and water to ensure they do not deteriorate prematurely. Periodically examine the outsourcing CV boot of wear and tear because the boots have to pivot regularly, check them, and look for tears, cracks, and loose clamps, and replace the boots demonstrating any forms of damage or lubricant leakage.