×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

Genuine Mazda Tribute Piston

Engine Pistons- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Piston found

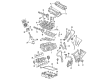

Mazda Tribute Pistons Part Number: ZZCA-11-100

$11.16 MSRP: $14.89You Save: $3.73 (26%)

Mazda Tribute Piston

Looking for Piston with proven quality? Choose OEM Piston. Mazda designs and builds them to strict factory specs. Every piece goes through rigorous quality checks. You'll get parts that fit right and work like new. Shop our huge inventory of OEM Mazda Tribute parts. Enjoy the highly competitive prices online. Our site is your one-stop shop. Each genuine Tribute part includes a manufacturer's warranty. Buy with confidence. Our return policy is simple and hassle-free. In a rush? Choose expedited delivery at checkout. You'll love the streamlined experience from search to checkout to receiving your order.

Mazda Tribute Piston Parts and Q&A

- Q: What is Top Dead Center (TDC) in relation to a Piston and how is it determined on Mazda Tribute?A:The peak of the cylinder that each piston passes as the crankshaft completes each rotation is known as the top dead center (TDC) which happens at the end of the compression and exhaust strokes, and TDC on the compression stroke of the Number 1 piston is used to determine the timing of the engine rotation. On 2012 and earlier models, disconnect the battery negative terminal, take all spark plugs out and the valve cover off and make sure that the crankshaft pulley is in place. Loose the lug nut in the right front wheel, and lift the vehicle and the wheel and fender splash shield. Turn the crankshaft until the intake valves of the Number 1 cylinder have been opened and closed and the TDC notch is lined up with the mark on the lowermost crankcase. The Camshafts are to be made horizontal and parallel to the height of the Cylinder Head at TDC which may be verified with a servicing tool made by the manufacturer or using a home manufactured metal strip. A timing hole also provides the opportunity to position, and a timing pin is recommended to fix the crankshaft on TDC. In case of lack of a timing pin, a TDC can be located by wood dowel by monitoring the position of the piston. The location of other cylinders can be obtained as the crankshaft is turned 180 degrees increments at a time after locating the Number 1 cylinder at TDC. Special instruments are needed in 2013 and later models such as camshaft position tool and a crankshaft timing pin. Disassemble battery, take off the required splash shields and drive belts, and in 1.5L and 1.6L, observe the TDC marks on camshaft sprocket. The TDC timing hole is found around the engine block and a timing pin can be employed to hold the crankshaft at TDC. In case of 2.0L models, make sure that the camshaft slots are horizontal and are at the same height as the cylinder head at TDC and take the required actions to make sure that the components are properly aligned and installed.