×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

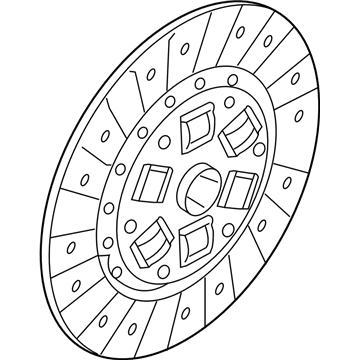

Genuine Mazda 3 Clutch Disc

Friction Disc- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 Clutch Discs found

Mazda 3 Disc Part Number: PE01-16-460

$145.14 MSRP: $193.55You Save: $48.41 (26%)Ships in 1-2 Business DaysMazda 3 Disc Part Number: PE02-16-460A

$125.76 MSRP: $167.71You Save: $41.95 (26%)Ships in 1-2 Business DaysMazda 3 Disc Part Number: PY11-16-460

$159.46 MSRP: $212.67You Save: $53.21 (26%)Ships in 1-2 Business DaysMazda 3 Disc Part Number: LF08-16-460A

$161.88 MSRP: $215.88You Save: $54.00 (26%)Ships in 1-2 Business DaysMazda 3 Disc Part Number: PY01-16-460

$173.55 MSRP: $231.45You Save: $57.90 (26%)Ships in 1-2 Business DaysMazda 3 Disc Part Number: PY12-16-460

$210.43 MSRP: $280.62You Save: $70.19 (26%)Ships in 1-2 Business DaysMazda 3 Disc Part Number: L304-16-460C

$242.16 MSRP: $322.94You Save: $80.78 (26%)Ships in 1-2 Business Days

Mazda 3 Clutch Disc

Looking for Clutch Disc with proven quality? Choose OEM Clutch Disc. Mazda designs and builds them to strict factory specs. Every piece goes through rigorous quality checks. You'll get parts that fit right and work like new. Shop our huge inventory of OEM Mazda 3 parts. Enjoy the highly competitive prices online. Our site is your one-stop shop. Each genuine 3 part includes a manufacturer's warranty. Buy with confidence. Our return policy is simple and hassle-free. In a rush? Choose expedited delivery at checkout. You'll love the streamlined experience from search to checkout to receiving your order.

Mazda 3 Clutch Disc Parts and Q&A

- Q: What features characterize vehicles with a manual transaxle and how can clutch disc problems be diagnosed on Mazda 3?A:Manual transaxle All vehicles with a single dry plate, diaphragm spring-type clutch, with the clutch disc having a splined hub that enables it to slide against the splines of the transaxle input shaft. The clutch and pressure plate are in contact with each other because of the spring pressure by the diaphragm at the pressure plate. The still clutch release system works by hydraulic pressure and comprises of the clutch pedal, a master cylinder with a common reservoir with the brake master cylinder, release cylinder and the hydraulic line involved. The release cylinder is pressurized by a pushrod through depression of the clutch pedal and the release cylinder forces the release bearing against the diaphragm fingers of the clutch pressure plate. Words may be different, common names of parts do not necessarily mean those used by the manufacturer; the driven plate can be also known as the clutch plate or disc and the Clutch Release Bearing can be known as a throwout bearing. Doing preliminary checks, except when replacing visibly damaged parts, to diagnose clutch problems: Check the level of the fluid in the Clutch Master Cylinder, add fluid where low, and inspect for leaks: and check the reservoir is dry, bleed the system and recheck the operation. Second, to determine the time of clutch spin-down, start the engine in the Neutral position (with clutch on) then switch off the clutch, wait a few seconds and change to Reverse and make sure there is no grinding sound as it will be a sign that the pressure plate or clutch disc is faulty. To confirm full release of the clutch run the engine with the parking brake on, press the clutch pedal about 1/2-inch off the floor and change between 1st gear and Reverse a few times; rough shifting indicates component failure. Lastly, physically examine the top of the clutch pedal pivot bushing to ensure that it is not bound or overly loose.

Related Mazda 3 Parts

Browse by Year

2023 Clutch Disc 2022 Clutch Disc 2021 Clutch Disc 2020 Clutch Disc 2019 Clutch Disc 2018 Clutch Disc 2017 Clutch Disc 2016 Clutch Disc 2015 Clutch Disc 2014 Clutch Disc 2013 Clutch Disc 2012 Clutch Disc 2011 Clutch Disc 2010 Clutch Disc 2009 Clutch Disc 2008 Clutch Disc 2007 Clutch Disc 2006 Clutch Disc 2005 Clutch Disc 2004 Clutch Disc