×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

Genuine Mazda 6 Shock Absorber

Suspension Shock Absorber- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

13 Shock Absorbers found

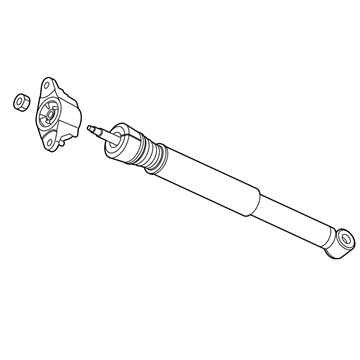

Mazda 6 Shock Part Number: GP9A-28-700C

$76.43 MSRP: $101.92You Save: $25.49 (26%)Ships in 1-2 Business DaysMazda 6 Shock Absorber Part Number: GSH7-28-700

$88.03 MSRP: $117.40You Save: $29.37 (26%)Ships in 1-2 Business DaysMazda 6 Shock Part Number: GS4H-28-700D

$89.03 MSRP: $118.72You Save: $29.69 (26%)Ships in 1-2 Business DaysMazda 6 Shock Part Number: GK2A-28-700D

$89.66 MSRP: $119.57You Save: $29.91 (26%)Ships in 1-2 Business DaysMazda 6 Shock Part Number: GR2F-28-700A

$94.08 MSRP: $125.46You Save: $31.38 (26%)Ships in 1-2 Business DaysMazda 6 Shock Part Number: GR1L-28-700A

$99.98 MSRP: $133.33You Save: $33.35 (26%)Ships in 1-2 Business DaysMazda 6 Shock Part Number: GJR9-28-910P

$119.76 MSRP: $159.72You Save: $39.96 (26%)Ships in 1-2 Business DaysMazda 6 Shock Part Number: GMN4-28-910A

$130.13 MSRP: $173.53You Save: $43.40 (26%)Ships in 1-2 Business DaysMazda 6 Shock Part Number: GJY9-28-910A

$133.69 MSRP: $178.29You Save: $44.60 (26%)Ships in 1-2 Business DaysMazda 6 Shock Part Number: GBFN-28-910B

$142.51 MSRP: $190.06You Save: $47.55 (26%)Ships in 1-2 Business DaysMazda 6 Shock Part Number: GSH7-28-910

$144.75 MSRP: $193.04You Save: $48.29 (26%)Ships in 1-2 Business DaysMazda 6 Shock Part Number: GS3L-28-700D

$149.38 MSRP: $199.20You Save: $49.82 (26%)Ships in 1-2 Business DaysMazda 6 Shock Part Number: GK2C-28-700E

Mazda 6 Shock Absorber

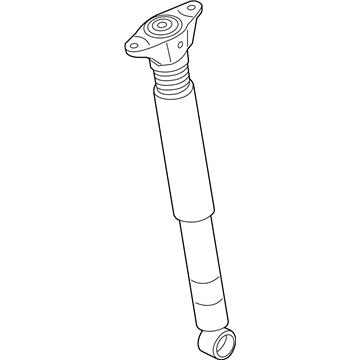

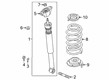

The Mazda 6 Shock Absorber cushions against bumps and potholes so the sedan is not hit by the kinetic jolts, converting them into small quantities of heat, enabling the passengers to have an easier ride. The Shock Absorbers, operating with coil springs, each have a hydraulic piston working in oil-filled passages to slow the suspension movement and ensure that the Mazda sedan's tires are in constant contact with the pavement. In its production, the car has been dependent on two primary damper formats. Twin-tube Shock Absorber models are widely applied to provide daily comfort on a wide range of road surfaces and conditions, and are sometimes augmented with pressurized gas to decrease foaming and extend lifespan. Sport trims are designed in the mono-tube format where all the parts are contained in a single barrel, and they cool off and can provide better control, which is valued by many Mazda enthusiasts. Subsequent modifications included the 6 upgrading its dampers with a spool-valve as well as position sensitive and acceleration sensitive damping technologies, which adjust the flow of the fluid to keep the ride steady on uneven streets but stiffen when the vehicle is taking corners. Mazda research vehicles have even demonstrated electrorheological or magnetorheological dampers that can vary within milliseconds towards future semi-active systems with an ideal combination of comfort and agility. Whatever version it is, a healthy Shock Absorber keeps all Mazdas together, comfortable and prepared for whatever the road throws at them.

Looking for Shock Absorber with proven quality? Choose OEM Shock Absorber. Mazda designs and builds them to strict factory specs. Every piece goes through rigorous quality checks. You'll get parts that fit right and work like new. Shop our huge inventory of OEM Mazda 6 parts. Enjoy the highly competitive prices online. Our site is your one-stop shop. Each genuine 6 part includes a manufacturer's warranty. Buy with confidence. Our return policy is simple and hassle-free. In a rush? Choose expedited delivery at checkout. You'll love the streamlined experience from search to checkout to receiving your order.

Mazda 6 Shock Absorber Parts and Q&A

- Q: Should the front suspension shock absorber or coil springs be disassembled and overhauled if they show signs of wear on Mazda 6?A:In case the front suspension Shock Absorber or Coil Springs exhibit signs of wear like leaking fluid, loss of damping ability, sagging, or broken coil springs they need to be disassembled and overhauled accordingly. The shock absorbers are non-serviceable and when faulty must be replaced, the springs and other component parts can be replaced individually. In order to uphold balanced properties on both aspects of the car, both sides of the car should be substituted at the same time. Start with stripping the assembly and removing all external dirt and then plant it in a vise. Install the coil spring compressor tools, making sure they are completely connected, and press the spring until all the tension is removed out of the upper mount. Align with an Allen key the shock absorber piston rod and unscrew with a box-end wrench the thrust bearing retaining nut. Take out the top mount and the upper spring seat and spring, boot, and bump stop. Should a new spring be to be fitted, the old spring must be removed very carefully out of the compressor; in case it is intended to be used again it may be left in compression. When the strut assembly is completely disassembled, inspect all parts of the assembly, wear and damage, check the bearing to operate smoothly, replacing parts as needed. Test the shock fluid leak, test the length of the piston rod of pitting and test the shock body damage. Check the operation of the shock, by shaking the piston through one complete stroke, and then through short strokes of 2 to 4 inches, and then verify that the resistance felt is a smooth, continuous resistance, jerky or uneven resistance, or any indication of wear or damage, is evidence that it is time to change the shock. Installation is done in the same order in which removal was done, that is, the coil springs are to be installed with the paint mark on the bottom and the coil spring ends to be properly engaged in the upper and lower seats before the compressor is released and the piston rod nut tightened to the correct torque.

Related Mazda 6 Parts

Browse by Year

2021 Shock Absorber 2020 Shock Absorber 2019 Shock Absorber 2018 Shock Absorber 2017 Shock Absorber 2016 Shock Absorber 2015 Shock Absorber 2014 Shock Absorber 2013 Shock Absorber 2012 Shock Absorber 2011 Shock Absorber 2010 Shock Absorber 2009 Shock Absorber 2008 Shock Absorber 2007 Shock Absorber 2006 Shock Absorber 2005 Shock Absorber 2004 Shock Absorber 2003 Shock Absorber