×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

Genuine Mazda MPV Brake Disc

Disc Rotor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

8 Brake Discs found

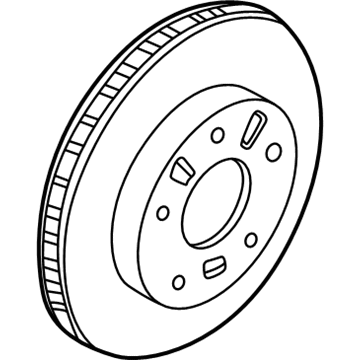

Mazda MPV Rotor Part Number: T002-33-25XA

$96.15 MSRP: $128.23You Save: $32.08 (26%)Ships in 1-2 Business DaysMazda MPV Rotor Part Number: L15Y-26-251

$96.24 MSRP: $128.34You Save: $32.10 (26%)Ships in 1-2 Business DaysMazda MPV Rotor Part Number: L003-33-25X

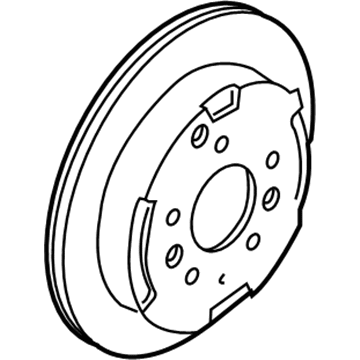

$89.86 MSRP: $119.84You Save: $29.98 (26%)Ships in 1-2 Business DaysMazda MPV Rotor Part Number: J001-26-251D

$51.56 MSRP: $67.68You Save: $16.12 (24%)Ships in 1-2 Business DaysMazda MPV Rotor Part Number: L001-33-251

$10.11 MSRP: $13.27You Save: $3.16 (24%)Ships in 1-2 Business DaysMazda MPV Rotor Part Number: J002-26-251A

Mazda MPV Rotor Part Number: L011-33-25X

Mazda MPV Rotor Part Number: LB82-33-25XA

Mazda MPV Brake Disc

Looking for Brake Disc with proven quality? Choose OEM Brake Disc. Mazda designs and builds them to strict factory specs. Every piece goes through rigorous quality checks. You'll get parts that fit right and work like new. Shop our huge inventory of OEM Mazda MPV parts. Enjoy the highly competitive prices online. Our site is your one-stop shop. Each genuine MPV part includes a manufacturer's warranty. Buy with confidence. Our return policy is simple and hassle-free. In a rush? Choose expedited delivery at checkout. You'll love the streamlined experience from search to checkout to receiving your order.

Mazda MPV Brake Disc Parts and Q&A

- Q: How to properly remove and install brake discs on Mazda MPV?A:Unscrew the lug nuts of the wheel, lift it up and hold it firmly in jackstands after which you remove the wheel(s). Unscrew the Brake Caliper and pull the brake pads out, but leave the Brake Hose connected to the caliper and hang the caliper away out of the way using a piece of wire, take care that the caliper does not hang by the hose or get stretched or twisted. A vehicle should not be placed in normal service before the brakes have been checked carefully. Look with naked eye at the disc surface to identify score marks and damage, though small scratches and shallow grooves are normal, deep score marks exceeding 0.015-inch must be removed and refinished. Inspection Check both sides of the disc, and in case it pulsates during braking, suspect disc runout and examine the wheel bearings as being worn. To verify runout of the disc, a dial indicator used, approximately 1/2-inch in position on the outer diameter of the disc, zeroed, and the disc turned; when the indication gets beyond the stop limit, the disc needs to be machined or replaced. Brake discs should be resurfaced to remove brake pedal pulsation and otherwise, brod off the glazing of the brake disc with swirling motion of sandpaper or emery cloth. Make sure that the disc is not machined any thinner than the lowest possible thickness, which is cast into the central part of the disc, and determine the thickness using a micrometer at a number of points close to the edge. Unbolt the front brake caliper mount on the steering knuckle, unscrew the retaining screws and unscrew the disc which is a tight fit perhaps requiring an impact screwdriver. Installation: The opposite of removal is tightening the caliper mount bolts and caliper lock bolts to the required torque and also the wheel lug nuts. Press the brake pedal several times to close the brakes pads on the disc, and test the brakes and ensure they are functioning properly before putting the vehicle into regular use.