×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

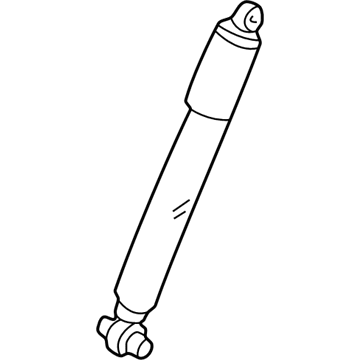

Genuine Mazda MPV Shock Absorber

Suspension Shock Absorber- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

8 Shock Absorbers found

Mazda MPV Shock Part Number: LD47-28-700

$85.94 MSRP: $114.61You Save: $28.67 (26%)Ships in 1-2 Business DaysMazda MPV Shock Part Number: L097-28-700A

$92.95 MSRP: $123.96You Save: $31.01 (26%)Ships in 1-2 Business DaysMazda MPV Shock Absorber Part Number: L018-28-700

$71.43 MSRP: $95.25You Save: $23.82 (26%)Ships in 1-2 Business DaysMazda MPV Shock Part Number: LA01-28-700B

$73.94 MSRP: $98.60You Save: $24.66 (26%)Ships in 1-2 Business DaysMazda MPV Shock Part Number: LA12-28-700B

$73.94 MSRP: $98.60You Save: $24.66 (26%)Ships in 1-2 Business DaysMazda MPV Shock Part Number: LA03-28-700B

Mazda MPV Strut Part Number: LA12-34-700-9U

Mazda MPV Shock Part Number: LA49-28-700

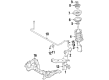

Mazda MPV Shock Absorber

Looking for Shock Absorber with proven quality? Choose OEM Shock Absorber. Mazda designs and builds them to strict factory specs. Every piece goes through rigorous quality checks. You'll get parts that fit right and work like new. Shop our huge inventory of OEM Mazda MPV parts. Enjoy the highly competitive prices online. Our site is your one-stop shop. Each genuine MPV part includes a manufacturer's warranty. Buy with confidence. Our return policy is simple and hassle-free. In a rush? Choose expedited delivery at checkout. You'll love the streamlined experience from search to checkout to receiving your order.

Mazda MPV Shock Absorber Parts and Q&A

- Q: What should you consider regarding Shock Absorbers before starting work on strut assemblies showing signs of wear on Mazda MPV?A:In case the struts or Coil Springs are indicated to possess any wear like leaking fluid, loss of damping capacity, or other physical signs like chips or cracks, then think over all the possible options before one undertakes any work because strut assemblies are not serviceable and, in case of any problem, they should be replaced. Springs-loaded strut assemblies can be offered on exchange basis and therefore can potentially save time and effort, so ensure cost and parts availability are checked before starting the disassembly. This procedure requires a spring compressor, which can be either hired on a daily basis at an auto part store or equipment yard. Start by taking out the strut(s) and machine the strut assembly in a vise being careful not to cut the jaws with wood or rag. A spring compressor should be installed following the instructions of the manufacturer and the spring compressor should be compressed until the upper seat is completely free of pressure that may be measured by wiggling the spring. Relax the nut of the damper shaft using a socket wrench, but do not allow the mounting block to enter a rotation using a prybar between two blocks of the mounting stud. Take out the nut, mounting block and upper seat, checking the bearing in the mounting block to ensure that it turns freely and examining the rubber part in the mounting block on whether it is in poor condition. Check the insulator in the upper seat, the seat of the upper seat, by cracking and hardness, and changing as required. Move the bump stop and dust boot out of the damper shaft and the ring rubber, and very cautiously remove the compressed spring out of the assembly, and put it somewhere safe. To reassemble, fit the ring rubber and bump stop/dust boot, passing the damper rod to full length and making sure it is correctly engaged. Install the coil spring on the lower seat making sure that the end of the spring is in the lowest section of the seat. Fit the rubber insulator to the upper spring seat then the upper seat and mounting block, aligning the flat in the D-shaped hole to the flat on the damper shaft and be sure that the out mark on the mounting block is facing in the right direction. Lastly, fit the damper shaft nut and screw it to the required torque employing a method to ensure that the shaft is not turned, and then replace the strut(s) again.

- Q: How to remove and install the shock absorber and strut assembly on Mazda MPV?A:To take off the front wheel, loosen the lug nuts, then raise the car and keep it firm on jackstands and then take out the wheel. Unscrew the bracket of the brake hose on the strut by taking off the U-clip, and the strut-to-steering knuckle nuts and bolts. Open the hood to access the four upper mounting nuts to the strut but do not forget to remove the ignition coil mounting bracket and then unscrew the strut to the steering knuckle and remove it off the car. Look at the coil spring and strut assembly in question to ensure that there is no fluid leakage, dents, damage, or corrosion appears. To install, place the strut with the top mounting studs so that the white mark of the mounting flange is facing inward and towards the front of the vehicle and then fit and screw the nuts to a given torque. Install the steering knuckle to the steering knuckle strut, by connecting the strut to the steering knuckle with bolts and nuts and tightening them to the required torque. Lastly, connect the brake hose with the strut bracket, install the clip, re-fit the wheels, lower the vehicle and attach the lug nuts to the desired torque.

Related Mazda MPV Parts

Browse by Year

2006 Shock Absorber 2005 Shock Absorber 2004 Shock Absorber 2003 Shock Absorber 2002 Shock Absorber 2001 Shock Absorber 2000 Shock Absorber 1998 Shock Absorber 1997 Shock Absorber 1996 Shock Absorber 1995 Shock Absorber 1994 Shock Absorber 1993 Shock Absorber 1992 Shock Absorber 1991 Shock Absorber 1990 Shock Absorber 1989 Shock Absorber