×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

Genuine Mazda Tribute Camshaft Position Sensor

Cam Position Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Camshaft Position Sensors found

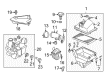

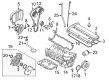

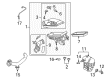

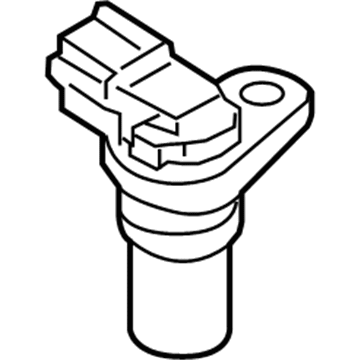

Mazda Tribute Camshaft Position Sensor Part Number: LF01-18-230

$25.89 MSRP: $34.52You Save: $8.63 (25%)Ships in 1-2 Business DaysMazda Tribute Camshaft Position Sensor Part Number: YF09-18-230

$28.39 MSRP: $37.86You Save: $9.47 (26%)Ships in 1-2 Business DaysMazda Tribute Camshaft Position Sensor Part Number: ZZC2-18-230A

$60.78 MSRP: $81.05You Save: $20.27 (26%)Mazda Tribute Camshaft Position Sensor Part Number: ZZCA-18-230B

$75.23 MSRP: $100.32You Save: $25.09 (26%)Mazda Tribute Camshaft Position Sensor Part Number: GY07-18-230A

Mazda Tribute Camshaft Position Sensor

Looking for Camshaft Position Sensor with proven quality? Choose OEM Camshaft Position Sensor. Mazda designs and builds them to strict factory specs. Every piece goes through rigorous quality checks. You'll get parts that fit right and work like new. Shop our huge inventory of OEM Mazda Tribute parts. Enjoy the highly competitive prices online. Our site is your one-stop shop. Each genuine Tribute part includes a manufacturer's warranty. Buy with confidence. Our return policy is simple and hassle-free. In a rush? Choose expedited delivery at checkout. You'll love the streamlined experience from search to checkout to receiving your order.

Mazda Tribute Camshaft Position Sensor Parts and Q&A

- Q: How to replace the Camshaft Position Sensor on Mazda Tribute?A:In 2012 and older four-cylinder models, begin by unhooking the cable of the negative battery terminal, then find the CMP sensor at the left rear side of the cylinder head and unhook the electrical connector. Take off the retaining-bolt of the CMP sensor and thereafter the sensor itself. Removal is the opposite of installation, whereby the CMP sensor bolt is screwed to the recommended torque. Once the battery has been reconnected, the Powertrain Control Module (PCM) should be relearned to respond to idle and fuel trim strategy to optimally perform. In V6 models, the procedure is same as in the case of V6 where the negative battery termination is disconnected and then the CMP sensor on the right end of the front cylinder head is disconnected by disconnecting the electrical connector, removing the retaining bolt after which the CMP sensor is removed. Once more, the process of installation is the opposite of the removal, and the consideration of torque requirements and PCM relearning. In 2013 models and subsequent models, the 1.5L, 1.6L and 2.0l CMP sensors are mounted on the top of the valve cover of the driver end. Uncover the engine, dislodge the electrical connector of the left CMP sensor and pulling the turbocharger piping and then dislodge the electrical connector and unbolt of the right CMP sensor to extricate the sensor. Examine the O-ring in case of reuse of the sensor, wipe it with clean engine oil during installation. When dealing with 2.5L engines, the engine cover is removed, the CMP sensor, which is positioned at the front corner of the driver side, is disconnected, the electrical connector is removed, the bolt is removed, and the CMP is pulled out, then O-ring inspection and lubrication is equally performed upon fitting it back.