×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

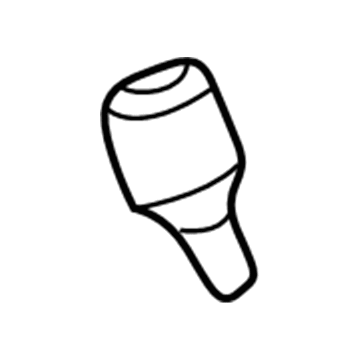

Genuine Mazda Ball Joint

Control Arm Joint- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

18 Ball Joints found

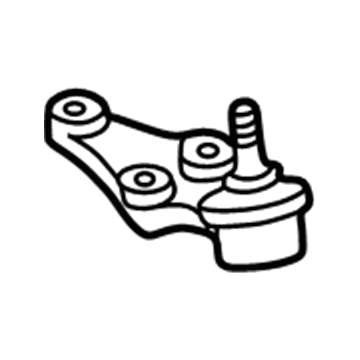

Mazda Ball Joint Part Number: T001-34-550B

$81.64 MSRP: $108.87You Save: $27.23 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Lower Ball Joint; Ball Joint

- Position: Lower

- Replaces: T001-34-550, T001-34-550A

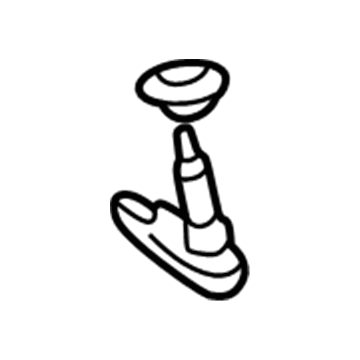

Mazda Lower Ball Joint Part Number: NA01-34-550B

$91.20 MSRP: $121.63You Save: $30.43 (26%)Ships in 1-2 Business DaysProduct Specifications- Position: Lower

- Replaces: NA01-34-550A, NA01-34-550

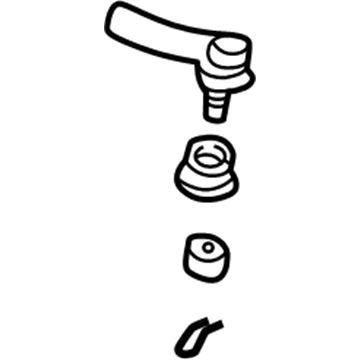

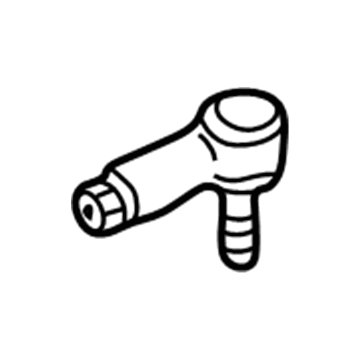

Mazda Outer Tie Rod Part Number: 8AF1-32-280

$98.34 MSRP: $131.14You Save: $32.80 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Ball Joint Set; Lower Ball Joint

- Position: Outer

- Replaced by: FB01-32-280

Mazda Ball Joint Part Number: B455-34-550

$78.34 MSRP: $104.47You Save: $26.13 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Lower Ball Joint

Mazda Ball Joint Part Number: E016-34-550

$78.89 MSRP: $105.21You Save: $26.32 (26%)Ships in 1-2 Business DaysProduct Specifications- Position: Lower

Mazda Ball Joint Part Number: 8AU1-34-540

$82.81 MSRP: $110.44You Save: $27.63 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Ball Joint Set; Upper Ball Joint

Mazda Ball Joint Part Number: FB01-34-550

$89.71 MSRP: $119.63You Save: $29.92 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Lower Ball Joint; Ball Joint

- Position: Lower

Mazda Ball Joint Part Number: 8AU2-34-510

$89.10 MSRP: $118.82You Save: $29.72 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Ball Joint Set; Lower Ball Joint

Mazda Lower Ball Joint Part Number: UC86-34-510A

$112.36 MSRP: $149.85You Save: $37.49 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Ball Joint; Lower Ball Joint

- Replaces: 8AU3-34-510

Mazda Ball Joint Part Number: LA12-34-550

$23.79 MSRP: $178.89You Save: $155.10 (87%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Lower Ball Joint

Mazda Ball Joint Part Number: BTDA-34-550

$333.68 MSRP: $444.99You Save: $111.31 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Lower Ball Joint; Ball Joint

- Position: Lower

- Replaces: B01A-34-550A

Mazda Ball Joint Part Number: ZZL0-34-550

$13.75 MSRP: $18.05You Save: $4.30 (24%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Lower Ball Joint

Mazda Lower Ball Joint Part Number: ZZP1-34-550

$52.75 MSRP: $70.35You Save: $17.60 (26%)Product Specifications- Other Name: Ball Joint, Lower

- Position: Lower

Mazda Outer Tie Rod Part Number: B092-32-280

Product Specifications- Other Name: Joint(Right), Ball-Outer; Lower Ball Joint, Outer Tie Rod

- Position: Outer Passenger Side

- Replaces: 8AB1-32-280

Mazda Lower Ball Joint Part Number: 1FFA-34-550

Product Specifications- Other Name: Ball Joint, Lower

- Position: Lower

Mazda Ball Joint Part Number: B092-34-550

Product Specifications- Position: Lower

Mazda Ball Joint Part Number: ZZL0-33-051

Product Specifications- Other Name: Pin; Ball Joint, Upper Ball Joint

Mazda Ball Joint Part Number: ZZM1-33-051

Product Specifications- Other Name: Joint Set, Axle Front; Ball Joint

Mazda Ball Joint

Every part of the car is important. Your vehicle's performance will be compromised if something goes wrong with the Mazda Ball Joint. Therefore, for your smooth driving and safety, you need regular checks and timely replacements. Whenever you need replacements, opt for genuine Mazda Ball Joints. Because they meet the manufacturer's criteria, it guarantees that replacements fit perfectly. Thus, these make better choices for people who care about driving. Why should you shop at MazdaPartsNow.com? We sell genuine Mazda Ball Joints. In our online catalog, there is a wide range of different parts. These are delivered directly from authorized Mazda dealers only so that customers can be sure of their security throughout any transaction while using our website. Furthermore, you can also quickly search for OEM parts you want because of our user-friendly site navigation. Choose us for a genuine Mazda Ball Joint that keeps your car running like new.

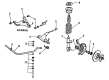

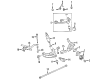

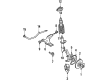

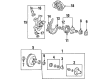

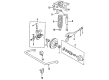

Mazda Ball Joint Parts and Q&A

- Q: How to inspect and replace dust seals and ball joints for 2-wheel drive front suspension on Mazda B2000?A:Check the dust seals and verify if they are fractured or brittle and change them in case of necessity. Test end play of upper and lower ball joints, when either has a play over 0.10mm (0.0039 in.), it is deemed flawed. On cars 1972-1984, front lift On jackstands under the frame, then use a floor jack to raise the lower control arm until the upper control arm is clear of the bumper stop. Take out the wheel, insert a chain into the coil spring to be sure, or apply a spring compressor and take out the cotter pin and nut that held the upper ball joint. Disconnect the ball joint to the spindle with a ball joint separator, unscrew the two upper arm retaining bolts and pull the arm off of the truck, counting and recording the location of any shims. Unscrew and remove the ball joint of the arm, and in installing, put the shims in their original position, and torque the two arm retaining bolts to 65-75 ft. lbs., the ball joint-to-arm bolts to 15-20 ft. lbs and the ball joint-to-spindle nut to 40-55 ft. lbs. To work with vehicles of 1986-89, elevate and stabilize the front part of the vehicle on jackstands below the frame, take off the wheels, and stabilize the lower arm on a floor jack. Unscrew the cotter pin and the nut on the upper ball joint and then disassemble the knuckle using a ball joint separator tool. Take the bushings and dust seals off the ends of the upper arm shaft and the nuts and bolts fastening the upper arm shaft to the support bracket and record the number and position of the shims to have the proper alignment of the wheels. Inspect all components of the parts that may be worn or damaged and substitute any suspect component. Measure the ball joint preload using a pull scale and adapter and the result must be 40 lb. or less. Unscrew and unbolt the ball joint out of the arm and during the installation screw the upper arm shaft mounting bolts to 60-68 ft. lbs., the ball joint-to-arm bolts to 15-20 ft. lbs. and the ball joint nut to 30-37 ft. lbs.

- Q: How to inspect and replace the upper ball joint on Mazda B2200?A:In case of inspection of the pickup, lift and secure the car up, then release the wheel and tire set. Jack up the lower control arm, make the brake and upper control arms separated and remove the cotter pin and nut of the upper ball joint stud. Apply a given tool to remove the upper ball joint and knuckle after which a pull scale should be attached to a ball joint stud and rocked back and forth and the pull scale reading to be taken between 4.4-7.7 lbs; and this should not be below otherwise, replace upper ball joint. In the case of the 2WD Navajo, lift the vehicle, place a jackstand under the I-beam axle, inspect the front wheel bearings and have a helper move the assembly of the wheel in and out as the upper spindle arm and axle jaw move; any movement of 0.8mm or more would mean that upper ball joints need to be replaced. When making removals and installations on the pickup, follow the same procedure as the first steps of rearing the vehicle and removing the wheel and tire combination and then maintain the lower control arm, dissociate the brake hose and separate the upper ball joint. Unscrew the upper ball joint that holds bolts, place the new ball joint assembly and tighten it with the required torque. In the 2WD Navajo, one must first lift the car, disassemble the wheel and tire assembly and then connect with the brake caliper, take off the brake rotor and dust shield, pull off the steering linkage, and take out the lower ball joint stud. Fix the axle and pop the lower ball joint loose and then detach the spindle and ball joint assembly. Removal of the lower ball joint of the spindle and later upper ball joint is done with a given tool. Installation requires pressing the upper ball joint first followed by the lower ball joint without heating them. Install the snapring, fit the spindle and ball joints into the axle and tighten the lower ball joint stud nut then install the clamp bolt and the remainder of the parts.