×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

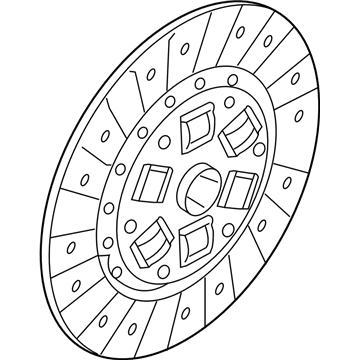

Genuine Mazda Clutch Disc

Friction Disc- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

41 Clutch Discs found

Mazda Disc Part Number: PE01-16-460

$145.14 MSRP: $193.55You Save: $48.41 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Disc, Clutch; Clutch

Mazda Disc Part Number: B631-16-460B-9U

$143.28 MSRP: $191.08You Save: $47.80 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Clutch Disc

Mazda Disc Part Number: B634-16-460C

$95.05 MSRP: $126.76You Save: $31.71 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Clutch Disc

- Replaces: B622-16-460A, B623-16-460B, B634-16-460, B634-16-460B-9U, B630-16-460, B634-16-460A-9U, B634-16-460A

Mazda Disc Part Number: HE11-16-460A

$17.74 MSRP: $126.77You Save: $109.03 (87%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Clutch Disc

Mazda Disc Part Number: L502-16-460

$94.24 MSRP: $125.68You Save: $31.44 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Clutch Disc

Mazda Disc Part Number: FS04-16-460C

$98.63 MSRP: $131.53You Save: $32.90 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Clutch Disc

Mazda Disc Part Number: KL07-16-460-9U

$100.35 MSRP: $133.83You Save: $33.48 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Clutch Disc

- Replaces: KL07-16-460

Mazda Disc Part Number: PE02-16-460A

$125.76 MSRP: $167.71You Save: $41.95 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Disc, Clutch

Mazda Disc Part Number: F208-16-460C

$121.28 MSRP: $161.73You Save: $40.45 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Clutch Disc

- Replaces: F208-16-460B

Mazda Disc Part Number: FS06-16-460A

$122.14 MSRP: $162.88You Save: $40.74 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Disc, Clutch

- Replaces: FS06-16-460

Mazda Disc Part Number: LF03-16-460A

$126.63 MSRP: $168.87You Save: $42.24 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Disc, Clutch

- Replaces: LF03-16-460

Mazda Disc Part Number: PE33-16-460

$156.63 MSRP: $208.87You Save: $52.24 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Disc, Clutch; Disc

Mazda Disc Part Number: PY11-16-460

$159.46 MSRP: $212.67You Save: $53.21 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Disc, Clutch; Disc

Mazda Disc Part Number: LF08-16-460A

$161.88 MSRP: $215.88You Save: $54.00 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Disc, Clutch

- Replaces: LF08-16-460, L301-16-460A, L301-16-460D, L302-16-460A, L303-16-460A, L303-16-460C, L301-16-460C, L302-16-460C

Mazda Disc Part Number: PY01-16-460

$173.55 MSRP: $231.45You Save: $57.90 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Disc, Clutch

Mazda Disc Part Number: L501-16-460A

$175.46 MSRP: $234.00You Save: $58.54 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Disc, Clutch

- Replaces: L501-16-460

Mazda Disc Part Number: N315-16-460D

$167.48 MSRP: $223.34You Save: $55.86 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Clutch Disc; Disc

- Replaces: N315-16-460D-9U

Mazda Disc Part Number: LF05-16-460A

$200.08 MSRP: $266.81You Save: $66.73 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Disc, Clutch

- Replaces: LF05-16-460

Mazda Disc Part Number: PY12-16-460

$210.43 MSRP: $280.62You Save: $70.19 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Disc, Clutch; Disc

Mazda Disc Part Number: BP07-16-460E-9U

Product Specifications- Other Name: Clutch Disc

- Replaces: BP07-16-460E, BP07-16-460D-9U, BP07-16-460C-9U, BP07-16-460D, BP07-16-460B, BP07-16-460C, BPY1-16-460

| Page 1 of 3 |Next >

1-20 of 41 Results

Mazda Clutch Disc

Every part of the car is important. Your vehicle's performance will be compromised if something goes wrong with the Mazda Clutch Disc. Therefore, for your smooth driving and safety, you need regular checks and timely replacements. Whenever you need replacements, opt for genuine Mazda Clutch Discs. Because they meet the manufacturer's criteria, it guarantees that replacements fit perfectly. Thus, these make better choices for people who care about driving. Why should you shop at MazdaPartsNow.com? We sell genuine Mazda Clutch Discs. In our online catalog, there is a wide range of different parts. These are delivered directly from authorized Mazda dealers only so that customers can be sure of their security throughout any transaction while using our website. Furthermore, you can also quickly search for OEM parts you want because of our user-friendly site navigation. Choose us for a genuine Mazda Clutch Disc that keeps your car running like new.

Mazda Clutch Disc Parts and Q&A

- Q: What steps are involved in diagnosing and servicing a hydraulic clutch disc system on Mazda 626?A:Since model year 1986, some of the models have hydraulic clutch release system installed which consists of the clutch pedal, master cylinder, fluid reservoir, hydraulic line, slave cylinder and clutch release bearing. The initial checks of the diagnosis of clutch system failure should monitor the fluid level in the master cylinder and leaks. To have full release of the clutch, travel of the release cylinder push-rod must be adjusted to have the pedal fully depressed. The height of the clutch pedal can be altered by using a distance between the pad of the pedal to the floor and changing the stopper bolt when needed. The height of free-play and disengagement should also be measured and adjusted by adjusting the push-rod to the master cylinder. To remove and install the clutch master cylinder, make sure you detach the negative battery cable, and remove the hydraulic line in a painstaking manner in order to prevent spillage of fluids. Once the master cylinder is firmly fixed, the hydraulic line is to be re-attached, and the system drained with DOT 3 brake fluid. Equally, in case of the release cylinder, the negative battery cable must be disconnected and the vehicle lifted off and the hydraulic line taken out, then the new cylinder should be installed and the hydraulic line reattached. It is necessary to bleed the hydraulic system, to make sure that the master cylinder contains new DOT 3 fluid, and it is performed with the help of a hose attached to bleeder valve when an assistant presses the clutch pedal. Once the system is checked to make sure that all air is removed and working properly, then the vehicle may be lowered back into service.

- Q: How to access and replace the clutch disc located between the engine and transmission on Mazda RX-7?A:The clutch components are located between the engine and the transmission and, therefore, one or the other component has to be removed. In case the repairs do not need engine removal, the quickest way to access the clutch is to remove the transmission. The first step is to take out the clutch release bearing and release fork out of the transmission; the bearing slides over the shaft of the transmission and the fork can be pulled through its rubber boot. It is important to note that before unscrewing the pressure plate and the clutch disc off the flywheel, a person should not bend or distort the metal fingers since it will not only lead to a replacement of the pressure plate. In order to hold the position of the pressure plate on the flywheel when replacing, cut an alignment mark with the small hole in the pressure plate mounting flange. Unscrew the six bolts connecting the pressure plate and the clutch disc to the flywheel, screwing them out gradually and in a diagonal manner to prevent deforming the assembly and again, two of the bolts are placed in larger, reamed holes in the mounting flange. Lastly, remove the pressure plate and clutch disc carefully and do not allow any of the oil or grease to spill on the disc lining or the pressure plate or flywheel surface.

Related Mazda Parts

Browse by Model

2 Clutch Disc 3 Clutch Disc 323 Clutch Disc 5 Clutch Disc 6 Clutch Disc 626 Clutch Disc B2000 Clutch Disc B2200 Clutch Disc B2300 Clutch Disc B2500 Clutch Disc B2600 Clutch Disc B3000 Clutch Disc B4000 Clutch Disc CX-5 Clutch Disc GLC Clutch Disc MX-3 Clutch Disc MX-5 Miata Clutch Disc MX-6 Clutch Disc Miata Clutch Disc Protege Clutch Disc Protege5 Clutch Disc RX-7 Clutch Disc RX-8 Clutch Disc Tribute Clutch Disc