×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

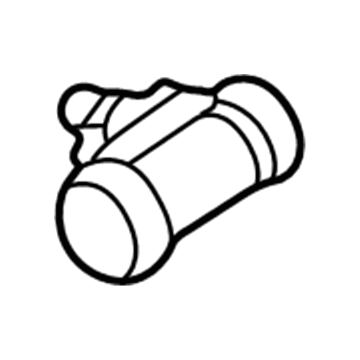

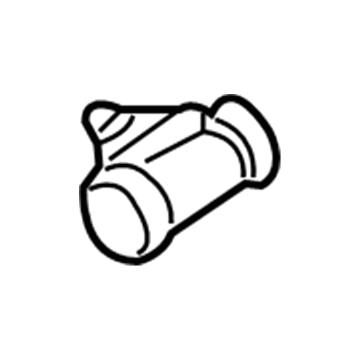

Genuine Mazda Wheel Cylinder

Brake Wheel Cylinder- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

22 Wheel Cylinders found

Mazda Wheel Cylinder Part Number: ECY1-26-710A

$48.78 MSRP: $65.05You Save: $16.27 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Cylinder, Wheel

- Replaces: EC01-26-610B, ECY1-26-710, EC01-26-610A

Mazda Wheel Cylinder Part Number: DF71-26-610

$52.24 MSRP: $69.66You Save: $17.42 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Cylinder, Wheel

Mazda Wheel Cylinder Part Number: LC62-26-610C

$40.84 MSRP: $54.47You Save: $13.63 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Cylinder, Wheel

- Replaces: LC62-26-610B, LC62-26-610

Mazda Wheel Cylinder Part Number: LA12-26-710

$45.63 MSRP: $60.85You Save: $15.22 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Cylinder, (Left), Rear Wheel

Mazda Wheel Cylinder Part Number: UA47-26-610

$55.70 MSRP: $74.28You Save: $18.58 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Cylinder (Right), Rear Wheel

Mazda Wheel Cylinder Part Number: GJ21-26-610D

$57.16 MSRP: $76.24You Save: $19.08 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Cylinder, Wheel; Wheel Cylinder Overhaul Kit

Mazda Wheel Cylinder Part Number: UB39-26-710

$59.21 MSRP: $78.97You Save: $19.76 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Cylinder, (Left), Rear Wheel

Mazda Wheel Cylinder Part Number: BC1D-26-610B

$9.65 MSRP: $12.67You Save: $3.02 (24%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Cylinder, Wheel

Mazda Wheel Cylinder Part Number: LA01-26-610

$8.06 MSRP: $10.59You Save: $2.53 (24%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Cylinder(Right), Rear Wheel

Mazda Wheel Cylinder Part Number: LA12-26-610

$8.18 MSRP: $10.74You Save: $2.56 (24%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Cylinder(Right), Rear Wheel

Mazda Wheel Cylinder Part Number: ZZC0-26-410

$47.94 MSRP: $63.93You Save: $15.99 (26%)Product Specifications- Other Name: Cylinder, Wheel

Mazda Wheel Cylinder Part Number: 1F60-26-610A

Product Specifications- Other Name: Cylinder, Wheel

Mazda Wheel Cylinder Part Number: 1F70-26-610A

Product Specifications- Other Name: Cylinder, Wheel

Mazda Wheel Cylinder Part Number: B216-26-610B

Product Specifications- Other Name: Cylinder, Wheel

Mazda Wheel Cylinder Part Number: B21H-26-610A

Product Specifications- Other Name: Cylinder, Wheel

- Replaces: B21H-26-610

Mazda Wheel Cylinder Part Number: G03026610

Product Specifications- Other Name: Cylinder Wheel

Mazda Wheel Cylinder Part Number: LA01-26-710

Product Specifications- Other Name: Cylinder Left, Rear Wheel

Mazda Wheel Cylinder Part Number: UB39-26-610

Product Specifications- Other Name: Cylinder(Right), Rear Wheel

Mazda Wheel Cylinder Part Number: ZZ0A-26-610

Product Specifications- Other Name: Cylinder, Wheel

Mazda Wheel Cylinder Part Number: ZZM026610B

Product Specifications- Other Name: Cylinder Right, Rear Wheel

| Page 1 of 2 |Next >

1-20 of 22 Results

Mazda Wheel Cylinder

Every part of the car is important. Your vehicle's performance will be compromised if something goes wrong with the Mazda Wheel Cylinder. Therefore, for your smooth driving and safety, you need regular checks and timely replacements. Whenever you need replacements, opt for genuine Mazda Wheel Cylinders. Because they meet the manufacturer's criteria, it guarantees that replacements fit perfectly. Thus, these make better choices for people who care about driving. Why should you shop at MazdaPartsNow.com? We sell genuine Mazda Wheel Cylinders. In our online catalog, there is a wide range of different parts. These are delivered directly from authorized Mazda dealers only so that customers can be sure of their security throughout any transaction while using our website. Furthermore, you can also quickly search for OEM parts you want because of our user-friendly site navigation. Choose us for a genuine Mazda Wheel Cylinder that keeps your car running like new.

Mazda Wheel Cylinder Parts and Q&A

- Q: How to remove and install a wheel cylinder on Mazda B2000?A:The procedure varies slightly to take the wheel cylinder off and off, however, first raise and support the rear end on jackstands, remove the brake drum and shoes. Disconnect and then plug at the wheel cylinder then remove the attaching nuts at the back of the backing plate and then remove the wheel cylinder. To overhaul, be sure to remove the wheel cylinder first, then the piston and adjusting screw, and then the boot and adjuster. The finished product Clean all parts using clean brake fluid Blow out piston cup, expander and spring with compressed air in inlet port. Check all parts of wear or damage replacing any worn, discoloured, misshapen, or suspicious parts. The cylinder bore can be honed to light score, pitting, or discolouration, otherwise with no effect, the survival of the interior can be achieved by honing, after which the cylinder can be discarded. Measure the piston-to-bore clearance, and on finding it more than 0.15mm (0.0059 in), change the cylinder. To assemble it, repeat the disassembling procedure but it is recommended to cover all the parts with clean brake fluid and then reassemble the whole, and lastly, the wheel cylinder along with the remaining parts need to be installed with the system being bled.

- Q: How to remove and install a wheel cylinder on Mazda B2200?A:In order to change and install the wheel cylinder, initially raise and support the rear end using jackstands then take off the brake drum and shoes. Unscrew and unscrew the brake line(s) in the wheel cylinder, and then screw out the backing plate attaching nuts at the back, then install in the same way. In the case of overhaul, kits can be supplied, but frequent use is made of a new or refurbished component. In case of an overhaul, it is important not to put contaminants in the system by fitting clean, fresh, and quality brake fluid. In case dirty fluid was used drain and flush the system, replace all the rubber parts and fill and bleed again. Start by taking off the wheel cylinder and putting it on a working bench. Pop off the old rubber boot, and clean out the rubber pistons, then scrape out the remaining parts of the inside, seals, spring-assembly, etc., with compressed air where possible. Wipe the cylinder and metal components with denatured alcohol or clean brake fluid, but not mineral based solvents. Air dry parts or blow them off with compressed air, checking the piston to make sure it is not scratched, and changing it where needed. Clean the cylinder bore and seals with clean brake fluid, install the spring assembly, insert the inner seals and pistons and new lubricant-free boots, then install lastly the wheel cylinder.

Related Mazda Parts

Browse by Model

2 Wheel Cylinder 323 Wheel Cylinder 626 Wheel Cylinder B2000 Wheel Cylinder B2200 Wheel Cylinder B2300 Wheel Cylinder B2500 Wheel Cylinder B2600 Wheel Cylinder B3000 Wheel Cylinder B4000 Wheel Cylinder MPV Wheel Cylinder MX-3 Wheel Cylinder MX-6 Wheel Cylinder Protege Wheel Cylinder Protege5 Wheel Cylinder Tribute Wheel Cylinder