×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

Genuine Mazda Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

46 Cylinder Heads found

Mazda Cylinder Head Part Number: 1F00-10-100R-0A

$771.21 MSRP: $1053.78You Save: $282.57 (27%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Cylinder Head, Reman(W/Valves)

- Replaces: 1F01-10-100A, 1F00-10-100A, 1F00-10-100, 1F01-10-100

Mazda Cylinder Head Part Number: B541-10-100D

$795.16 MSRP: $1086.50You Save: $291.34 (27%)Ships in 1-2 Business DaysMazda Cylinder Head Part Number: FS7N-10-100

$852.29 MSRP: $1164.57You Save: $312.28 (27%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Head, Cylinder, Bare

Mazda Cylinder Head Part Number: L504-10-090

$954.53 MSRP: $1304.25You Save: $349.72 (27%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Cylinder Head, Complete

Mazda Cylinder Head Part Number: LFE2-10-090K

$1055.48 MSRP: $1442.21You Save: $386.73 (27%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Head, Cylinder

- Replaces: LFE2-10-090E, LFE2-10-090J, LFE2-10-090G, LFE2-10-090F, LFE2-10-090C

Mazda Cylinder Head Part Number: PEKC-10-100

$1060.56 MSRP: $1449.14You Save: $388.58 (27%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Head, Cylinder

Mazda Cylinder Head Part Number: B61P-10-100H

$1098.05 MSRP: $1500.37You Save: $402.32 (27%)Ships in 1-2 Business DaysMazda Cylinder Head Part Number: YF71-10-100R-00

$1094.35 MSRP: $1491.01You Save: $396.66 (27%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Reman, Head Cyclinder

- Replaces: YF71-10-100

Mazda Cylinder Head Part Number: PYFA-10-100E

$1160.35 MSRP: $1585.50You Save: $425.15 (27%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Cylinder Head

Mazda Cylinder Head Part Number: FSD7-10-100

$1153.96 MSRP: $1576.76You Save: $422.80 (27%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Head, Cylinder

Mazda Cylinder Head Part Number: L3N5-10-090L

$1225.43 MSRP: $1674.41You Save: $448.98 (27%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Head, Cylinder

- Replaces: L3N5-10-090F, L3G6-10-090H, L3N5-10-090K, L3N5-10-090G, L3N5-10-090H

Mazda Cylinder Head Part Number: BP4W-10-100C

$1365.68 MSRP: $1866.05You Save: $500.37 (27%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Head, Cylinder

- Replaces: BP4W-10-100B

Mazda Cylinder Head Part Number: L3K9-10-090G

$1506.98 MSRP: $2059.13You Save: $552.15 (27%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Head, Cylinder

- Replaces: L3K9-10-090C, L3K9-10-090F, L3K9-10-090A

Mazda Cylinder Head Part Number: PEES-10-100A

$1639.55 MSRP: $2240.27You Save: $600.72 (27%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Head, Cylinder

Mazda Cylinder Head Part Number: PE31-10-100A

$1556.40 MSRP: $2126.66You Save: $570.26 (27%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Head, Cylinder; Cylinder Head

Mazda Cylinder Head Part Number: CA01-10-1A0E

$1639.30 MSRP: $2239.94You Save: $600.64 (27%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Head(Left), Cylinder

- Replaces: CA01-10-1A0B, CA01-10-1A0D, CA01-10-1A0A, CA01-10-1A0C

Mazda Cylinder Head Part Number: CA01-10-100D

$1661.99 MSRP: $2270.93You Save: $608.94 (27%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Head(Right), Cylinder

- Replaces: CA01-10-100C, CA01-10-100A, CA01-10-100B

Mazda Cylinder Head Part Number: LF9G-10-090A

$1885.94 MSRP: $2576.93You Save: $690.99 (27%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Head, Cylinder

- Replaces: LF9G-10-090

Mazda Cylinder Head Part Number: 1F20-10-100R-00

Mazda Cylinder Head Part Number: 1FAA-10-0K0R-00

Product Specifications- Other Name: Head Left, Cylinder

| Page 1 of 3 |Next >

1-20 of 46 Results

Mazda Cylinder Head

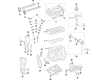

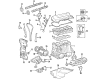

The mechanics consider the cylinder head very important. It is found on top of the engine block. It closes the cylinder with pistons by using gaskets and safeguards other parts that are fragile and deserve care in an engine. It is the role that a Mazda cylinder head has to play in maintaining vacuum conditions within the engine, thereby preventing wear and tear on engine parts. Nonetheless, if there are leaks, cracks, or any other mechanical issues with this part of the car, it can cause the internal combustion engine to malfunction. Do not wait too long before acting on any impending problem as far as this matter is concerned. If you perceive a problem with your motor's cylinder head, then stop driving immediately, for it may need replacement.

Whenever you need replacements, opt for genuine Mazda Cylinder Heads. Because they meet the manufacturer's criteria, it guarantees that replacements fit perfectly. Thus, these make better choices for people who care about driving. Why should you shop at MazdaPartsNow.com? We sell genuine Mazda Cylinder Heads. In our online catalog, there is a wide range of different parts. These are delivered directly from authorized Mazda dealers only so that customers can be sure of their security throughout any transaction while using our website. Furthermore, you can also quickly search for OEM parts you want because of our user-friendly site navigation. Choose us for a genuine Mazda Cylinder Head that keeps your car running like new.

Mazda Cylinder Head Parts and Q&A

- Q: What are the basic types of cylinder heads used in today's automobiles on Mazda Millenia?A:Cylinder heads on the current automobiles come in two fundamental types: Overhead Valve (OHV) and Overhead Camshaft (OHC) which is subdivided into Single Overhead Camshaft (SOHC) and Dual Overhead Camshaft (DOHC). In general, a head with a single camshaft is merely referred to as an OHC head and an engine that uses a OHV cylinder head is referred to as a pushrod engine. Cylinder heads are manufactured mostly of the aluminum alloy, because of its lightness, strength, and thermal conduction but cast iron is also extensively used in many automobiles. Every cylinder head has valves and seats and some of these engines have two valves per cylinder and advanced engines have multi-valve arrangements. The valve is known to contact the seat on the precision machined surfaces, to cover the combustion chamber and also the valve has a guide which centers it and enables motion. Adequate clearance between the guide and valve is very important, too much clearance may result in oil consumption and damage whereas too little clearance may result in sticking. Valve springs are used to stabilize the valves on the seats and put them back into position when they are open. Ideally, the process of rebuilding a cylinder head will also require replacement of all the valves, guides, seals and springs however this may not be the case depending on the maintenance of the engine. Other typical causes of wear are that with improper tuning, the wear may be very rapid due to oil washing out or overly high temperatures of combustion. All components are also impacted by mileage and although most of them can be machined and re-used, burnt valves are to be replaced as well as any other worn parts. The process of disassembly of either of the two cylinder head types is the same, with special consideration to labeling of parts, particularly with the dual camshaft heads. C-clamp style valve spring compressor and OHC spring removal tool are required in the case of cup-type camshaft followers, and a typical valve spring compressor might be used in the case of rocker arm-type followers. The cleaning components are inspected by checking valves which may have cracks, wear as well as tulipping and also measuring valve stem diameters. Checking springs, retainers and valve locks must also be checked to ensure they are not broken or worn out and the cylinder head in question must also be examined to determine the condition of the guides, wear of the seats, levelness of the surface and cracks. Valve guide repair procedures are knurling, inserts, oversizing of reaming, and replacing and valve seat should be centered to value guide. In case the cylinder head is distorted, it should be flattened and the cracks might need repairing by a professional. Assembling involves a working area, greasing of the stem of the valves and fitting parts in their correct places making sure all parts are in their proper places and fitted.

- Q: How to Disassemble a Cylinder Head on Mazda Protege?A:Most engines commonly have new and rebuilt cylinder heads which are readily available at dealerships and auto parts stores and it is more practical and economical for home mechanics to buy a replacement head than to disassemble, inspect and refurbish the old one because of the specialized tools and the unavailability of replacement parts. Disassembly entails the removal of the intake and exhaust valves as well as other associated parts, in the assumption that the lifters and camshafts are already removed. It is also necessary to remove the valves in their components and store them in order to be reinstalled in the same valve guides. Removing the first valve To take out the springs, press a spring compressor, remove the keepers, and then scale back the compressor with care to leave retainer, spring and spring seat attached, without damaging the bores of the lifters. When a valve binds in the guide, there is a possibility that the keeper groove should be deburred around. The same must be applied to all the valves that are left over with everything arranged so when they are installed again. Once all the valves and parts have been taken off and stored, cleaning and inspection of the head must be completed, the job of dismantling the engine may also be done at this stage should a complete overhaul be being completed before the cleaning and inspection of the cylinder head begins.

Related Mazda Parts

Browse by Model

2 Cylinder Head 3 Cylinder Head 5 Cylinder Head 6 Cylinder Head 626 Cylinder Head 929 Cylinder Head B2300 Cylinder Head B2600 Cylinder Head B3000 Cylinder Head B4000 Cylinder Head CX-5 Cylinder Head CX-7 Cylinder Head CX-9 Cylinder Head MPV Cylinder Head MX-3 Cylinder Head MX-5 Miata Cylinder Head Miata Cylinder Head Millenia Cylinder Head Protege Cylinder Head Protege5 Cylinder Head Tribute Cylinder Head