×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

Genuine Mazda Brake Hose

Brake Line- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

157 Brake Hoses found

Mazda Brake Tube Part Number: DF71-43-650A

$7.06 MSRP: $9.41You Save: $2.35 (25%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pipe(Right), Brake-Rear

- Position: Right

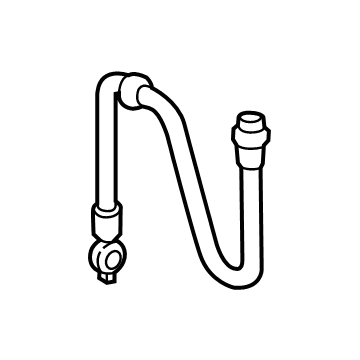

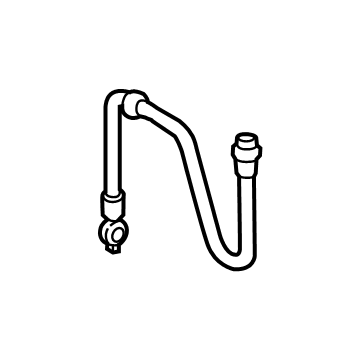

Mazda Brake Hose Part Number: BADE-43-810

$12.36 MSRP: $16.48You Save: $4.12 (25%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose, Flexible; Brake Hose

Mazda Brake Line Part Number: LC62-43-650A

$2.04 MSRP: $2.68You Save: $0.64 (24%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pipe(Right), Brake-Rear

- Position: Right

Mazda Brake Hose Part Number: VA40-43-980

$15.40 MSRP: $20.53You Save: $5.13 (25%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose(Right), Flexible-Front; Brake Hose

- Position: Right

- Replaced by: VA40-43-980A

Mazda Brake Hose Part Number: VA40-43-990

$15.40 MSRP: $20.53You Save: $5.13 (25%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose(Left), Flexible-Front; Brake Hose

- Position: Left

- Replaced by: VA40-43-990A

Mazda Flex Hose Part Number: DGH9-43-820

$30.40 MSRP: $40.54You Save: $10.14 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose, Flexible; Brake Hose, Flex Hose

- Position: Left

- Replaced by: DGH9-43-820A

Mazda Flex Hose Part Number: DGH9-43-810

$325.05 MSRP: $433.49You Save: $108.44 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose, Flexible; Brake Hose, Flex Hose

- Position: Right

- Replaced by: DGH9-43-810A

Mazda Brake Hose Part Number: VA40-43-810

$18.41 MSRP: $24.55You Save: $6.14 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose, Flexible; Brake Hose

- Position: Right

Mazda Brake Hose Part Number: VA40-43-820

$18.41 MSRP: $24.55You Save: $6.14 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose, Flexible; Brake Hose

- Position: Left

Mazda Brake Hose Part Number: BDTS-43-820A

$19.96 MSRP: $26.62You Save: $6.66 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose(Left), Flexible; Brake Hose

- Position: Left

- Replaced by: BDTS-43-820B

Mazda Flex Hose Part Number: DGH9-43-980A

$21.38 MSRP: $28.51You Save: $7.13 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose, Flexible; Brake Hose, Flex Hose

- Position: Right

- Replaced by: DGH9-43-980B

- Replaces: DGH9-43-980

Mazda Flex Hose Part Number: DGH9-43-990A

$325.05 MSRP: $433.49You Save: $108.44 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose(Left), Flexible-Front; Brake Hose, Flex Hose

- Position: Left

- Replaced by: DGH9-43-990B

- Replaces: DGH9-43-990

Mazda Flex Hose Part Number: BJS7-43-980A

$21.75 MSRP: $29.00You Save: $7.25 (25%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose, Flexible; Flex Hose

- Position: Right

Mazda Brake Hose Part Number: BCKA-45-280

$22.30 MSRP: $29.74You Save: $7.44 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pipe(Right), Brake-Front; Brake Hose

- Position: Right

Mazda Flex Hose Part Number: GA7B-43-810

$23.05 MSRP: $30.74You Save: $7.69 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose, Flexible; Flex Hose

Mazda Flex Hose Part Number: 1F70-43-980

$3.57 MSRP: $29.72You Save: $26.15 (88%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose, Flexible; Flex Hose

- Position: Right

- Replaces: 1F00-43-980

Mazda Flex Hose Part Number: 1F70-43-990

$22.99 MSRP: $30.66You Save: $7.67 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose(Left), Flexible-Front; Flex Hose

- Position: Left

- Replaces: 1F00-43-990, ZZP1-43-990

Mazda Flex Hose Part Number: DGJ4-43-810

$23.18 MSRP: $30.91You Save: $7.73 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose, Flexible; Brake Hose, Flex Hose

- Position: Right

- Replaced by: DGJ4-43-810A

Mazda Flex Hose Part Number: K011-43-810B

$25.83 MSRP: $34.43You Save: $8.60 (25%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose, Flexible; Brake Hose, Flex Hose

- Replaces: K011-43-810, K011-43-810A

Mazda Flex Hose Part Number: EC01-43-980D

Product Specifications- Other Name: Hose, Flex; Flex Hose

- Replaces: EC01-43-980B, EC01-43-980, EC01-43-980C, EC01-43-980A, ZZC0-43-980

| Page 1 of 8 |Next >

1-20 of 157 Results

Mazda Brake Hose

Every part of the car is important. Your vehicle's performance will be compromised if something goes wrong with the Mazda Brake Hose. Therefore, for your smooth driving and safety, you need regular checks and timely replacements. Whenever you need replacements, opt for genuine Mazda Brake Hoses. Because they meet the manufacturer's criteria, it guarantees that replacements fit perfectly. Thus, these make better choices for people who care about driving. Why should you shop at MazdaPartsNow.com? We sell genuine Mazda Brake Hoses. In our online catalog, there is a wide range of different parts. These are delivered directly from authorized Mazda dealers only so that customers can be sure of their security throughout any transaction while using our website. Furthermore, you can also quickly search for OEM parts you want because of our user-friendly site navigation. Choose us for a genuine Mazda Brake Hose that keeps your car running like new.

Mazda Brake Hose Parts and Q&A

- Q: How often should you inspect the Brake Hose connecting the steel brake lines to the brake assemblies on Mazda 6?A:Open the vehicle, raise it up, and place on jackstands, approximately every six months, the flexible hoses between the steel brake lines and the front and rear brake assemblies; check them with regards to cracks, chafing, leaking, blistering, etc. as these are vital components of the braking system. A light and a reflecting mirror will also help in a complete check and a defective hose must be taken out and replaced with a new one. The first step is to make the ends of the hose clean, after which a flare-nut wrench is used to unscrew the tube nut to prevent rounding off of the corners, and then loosen the bolt(s) or clip(s) holding the hose. In the case of front brake hoses, unscrew brake line fitting and hold the fitting block in place with another wrench, remove mounting bolts and remove the hose on the caliper by unscrewing the banjo bolt. In the case of rear brake hoses, use the pliers to hold the bracket, then deattach the clip and the hose of the caliper. Disconnect hose to caliper, unscrew the sealing washers and screw the new brake hose in place with new sealing washers tightening the banjo fitting bolt to a prescribed torque. Turn the removal process back to fit the hose, make sure it is not twisted and make sure this hose does not come into contact with the suspension or steering parts and have an assistant push down on the vehicle and turn the steering wheel lock-to-lock as part of the inspection. When changing brake lines, it is important to use the right parts and never use copper tubing and buy steel brake lines at the dealer or auto parts store. Ready-made brake lines that have flared ends and fittings are offered and can be bent with a tubing bender to the required shapes. Make sure that the new line is securely held in place in the brackets with plenty of clearance of moving or hot objects. Once installed, verify the level of the master cylinder fluid, fill it, and Bleed the brake system, test the brakes thoroughly, and put the vehicle back into normal operation.

- Q: How often should you inspect the Brake Hose connecting the steel brake lines to the brake assemblies on Mazda 3?A:Check the brake system, and the flexible hoses are the most important and delicate components that should be carefully examined with a light and a mirror under every six months, when the vehicle is raised, and the hoses are safely fastened on jackstands, inspecting them for cracks, chafing, leaks, blisters and other damages. In case of any defects, a new hose should be used. First wipe off all the dirt on the ends of the hose and then unscrew using a flare-nut wrench the tube nut that attaches the hose to the frame bracket, unscrew the clip and then attach the hose. Then unbolt or unclip any hose in place on the other brackets and unscrew the hose off of the caliper. Install the new brake hose screwing it to the caliper and screwing the tube nut fitting to the recommended torque without twisting the hose. Ensure that there is no contact between suspension or steering elements and the hose, and start bleeding the brake system. When changing the brake lines be sure that you use the right parts as do not use copper tubing in any part of the brake system and buy steel brake lines at a car dealership or auto parts store. Ready-made brake lines that have flared ends of tubes and fitted components are ready and may be bent to the necessary shapes with a tubing bender. Make sure that the new line is firmly seated in the brackets with ample clearance of moving or hot parts, inspect the master cylinder fluid level, and add fluid where needed and carefully test the brakes and return the vehicle to normal operation.

Related Mazda Parts

Browse by Model

2 Brake Hose 3 Brake Hose 323 Brake Hose 5 Brake Hose 6 Brake Hose 626 Brake Hose 929 Brake Hose B2000 Brake Hose B2200 Brake Hose B2300 Brake Hose B2500 Brake Hose B2600 Brake Hose B3000 Brake Hose B4000 Brake Hose CX-3 Brake Hose CX-30 Brake Hose CX-5 Brake Hose CX-50 Brake Hose CX-7 Brake Hose CX-9 Brake Hose GLC Brake Hose MPV Brake Hose MX-3 Brake Hose MX-30 EV Brake Hose MX-5 Miata Brake Hose MX-6 Brake Hose Miata Brake Hose Millenia Brake Hose Navajo Brake Hose Protege Brake Hose Protege5 Brake Hose RX-7 Brake Hose RX-8 Brake Hose Tribute Brake Hose