×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

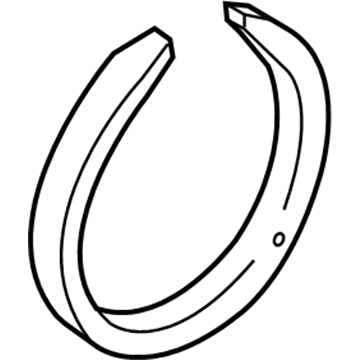

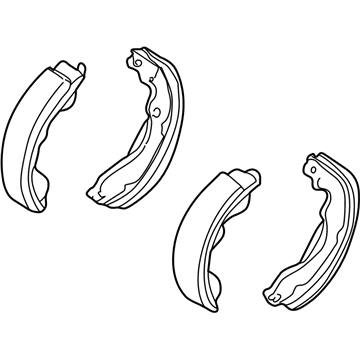

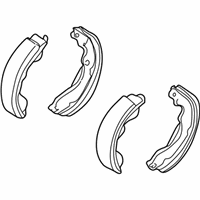

Genuine Mazda Brake Shoe Set

Brake Shoe- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

29 Brake Shoe Sets found

Mazda Shoes Part Number: EFY7-44-39Z

$11.62 MSRP: $81.40You Save: $69.78 (86%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Shoe Set, Rear Parking Brake; Shoes

Mazda Shoes Part Number: 1F60-26-310

$58.03 MSRP: $77.38You Save: $19.35 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Shoe Set, Brake-Rear; Brake Shoes

- Replaces: 1F60-26-310A

Mazda Shoes Part Number: LFY4-44-39Z

$61.33 MSRP: $81.78You Save: $20.45 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Shoe Set, Rear Parking Brake; Brake Shoes

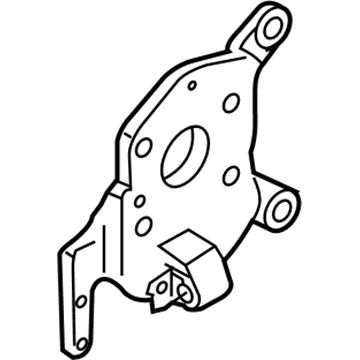

Mazda Plate Part Number: LE44-44-290B

$9.83 MSRP: $80.21You Save: $70.38 (88%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Plate(Left), Back; Plate

- Position: Left

- Replaces: LE44-44-600G

Mazda Shoes Part Number: EGY3-44-39Z

$76.55 MSRP: $102.08You Save: $25.53 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Shoe Set, Rear Parking Brake; Shoes

Mazda Shoes Part Number: DAY4-26-38Z

$97.23 MSRP: $129.66You Save: $32.43 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Shoe Set, Brake-Rear; Brake Shoes, Shoes

- Position: Rear

- Replaces: DFY1-26-38Z, DFY1-26-38ZA

Mazda Shoes Part Number: LDY4-26-38ZA

$100.31 MSRP: $133.78You Save: $33.47 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Shoe Set, Brake-Rear; Shoes

Mazda Brake Shoes Part Number: LEY4-44-39Z

$17.42 MSRP: $140.73You Save: $123.31 (88%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Shoe Set, Rear Park Brake

- Position: Right

Mazda Rear Shoes Part Number: BCYD-26-38ZA

$8.85 MSRP: $64.25You Save: $55.40 (87%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Shoe Set, Brake-Rear

- Position: Rear

Mazda Shoes Part Number: B5Y7-26-38Z

$49.01 MSRP: $65.36You Save: $16.35 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Shoe Set, Brake-Rear; Rear Shoes

Mazda Shoes Part Number: UB39-26-38ZA

$56.33 MSRP: $75.12You Save: $18.79 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Shoe Set, Brake-Rear

- Replaces: UB39-26-38Z

Mazda Shoes Part Number: GJ83-26-38ZA

$58.60 MSRP: $78.15You Save: $19.55 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Shoe Set, Brake-Rear; Shoes

- Position: Rear

- Replaces: GJ21-26-38Z

Mazda Shoes Part Number: LAY3-26-38ZB

$98.14 MSRP: $130.88You Save: $32.74 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Shoe Set, Brake-Rear

Mazda Shoes Part Number: LB40-44-39Z

$101.60 MSRP: $135.49You Save: $33.89 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Shoe Set, Rear Parking Brake

Mazda Rear Shoes Part Number: BL53-26-38Z

$6.72 MSRP: $8.82You Save: $2.10 (24%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Shoe Set, Brake-Rear

- Position: Rear

- Replaces: B092-26-38Z

Mazda Shoes Part Number: BJYM-26-38Z

Product Specifications- Other Name: Shoe Set, Brake-Rear; Shoes

- Replaces: B2YD-26-38Z, B2YD-26-38ZA

Mazda Shoes Part Number: 1F61-26-310B

Product Specifications- Other Name: Shoe Set, Brake-Rear; Brake Shoes

Mazda Shoes Part Number: 1F80-26-310

Product Specifications- Other Name: Shoe Set, Brake-Rear; Brake Shoes

Mazda Shoes Part Number: BWYB-26-38Z

Product Specifications- Other Name: Shoe Set, Brake-Rear; Shoes

- Position: Rear

Mazda Rear Shoes Part Number: G0Y0-26-38Z

Product Specifications- Other Name: Shoe Set, Brake-Rear

- Position: Rear

| Page 1 of 2 |Next >

1-20 of 29 Results

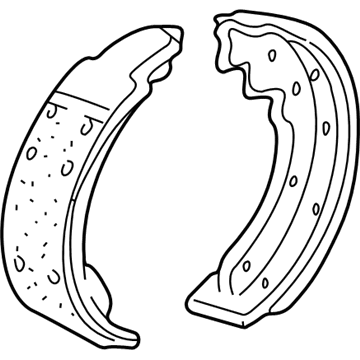

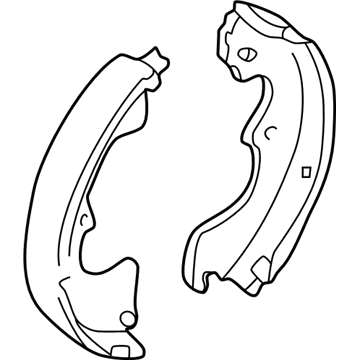

Mazda Brake Shoe Set

Every part of the car is important. Your vehicle's performance will be compromised if something goes wrong with the Mazda Brake Shoe Set. Therefore, for your smooth driving and safety, you need regular checks and timely replacements. Whenever you need replacements, opt for genuine Mazda Brake Shoe Sets. Because they meet the manufacturer's criteria, it guarantees that replacements fit perfectly. Thus, these make better choices for people who care about driving. Why should you shop at MazdaPartsNow.com? We sell genuine Mazda Brake Shoe Sets. In our online catalog, there is a wide range of different parts. These are delivered directly from authorized Mazda dealers only so that customers can be sure of their security throughout any transaction while using our website. Furthermore, you can also quickly search for OEM parts you want because of our user-friendly site navigation. Choose us for a genuine Mazda Brake Shoe Set that keeps your car running like new.

Mazda Brake Shoe Set Parts and Q&A

- Q: How to remove and install a front Brake Shoe Set on Mazda B2000?A:The steps to install and remove the brake components would require one to buy a cheap brake spring tool to make the process easy. The first step involves jackstanding and lifting the front end and removing drums and retracting springs. Then remove the holddown springs and guide pins by turning the collars right 90 degrees using pliers or spring tool to release the springs then removing the shoes taking note of the shoe with the longer lining. Examine the shoes in relation to cracks or heat checking or oil or grease contamination, and the minimum lining thickness must be 1.00mm (0.039 in.). Wheel cylinders can be rebuilt or replaced in case of any heat checking or discoloration. It is necessary to change shoes one on each side of the car. Wipe the backing plate with a recommended cleaning solution, and grease the threads of the starwheel with lithium or silicone lubricant and put a drop on the pads on which the brake shoes slide. To install it the parking brake lever should be slipped to the new shoe, and the shoes to the backing plate, and the parking brake cable to the lever. Next come the holddown springs and guide pins then the adjusting pawl and spring, then the adjusting screw assembly and finally the retracting springs and drums. The brake may be adjusted by reaching through the holes in the backing plate with a brake adjusting spoon, to turn the star wheel screw, until the wheel is locked and turn back the star-wheel by about 6-7 clicks until the wheel turns freely. Make sure that the adjustment is the same on both wheels, push the parking brake, and push the brake pedal just a few times; if the brakes are spongy then bleed the system.

- Q: What precautions should be taken when replacing a Brake Shoe Set and its associated components on Mazda Protege?A:The return and hold down springs should be changed whenever the brake shoes are changed since the springs are subjected to constant heating and cooling and thus the spring tension reduces with time and might even drag the shoes to the drum thus wear out faster. The first thing is to loosen the lug nuts on the wheels, elevate the rear of the car and firmly hold it on jackstands without rolling the front wheels. Squeeze the parking brake and take away the wheel, inspecting the brake shoe linings, also checking the brake wheel cylinder, whether it does not have leaks, in this case, fix the brake wheel cylinder. Both rear wheels need to be changed by changing all the four brake shoes as one and not at the same time to avoid confusion of parts. Use the instructions to follow the steps of changing the brake shoes, and the correlation between the drum and the hub should be noted, to keep the balance in dynamics upon reassembling. Take out the drum retention screws, loosen the brake drum by bolts in case it is stuck and remove the drum. Put a drain pan beneath the brake assembly, spray it with brake cleaner and leave it to dry without taking compressed air. Unscrew the upper and lower return springs of the shoes and then with a hold-down spring tool or a pliers unscrew the leading and trailing shoe hold-down pins and springs and then the leading shoe. Take off the anti-rattle spring on adjuster and trailing shoe, and put high temperature grease on the points of contact of the shoe on the backing plate. On the front side depress the wheel cylinder piston and fit the leading shoe with his hold-down pin and spring, and then the lower return spring. Make sure that you put everything together, cross-check with the other side in case of doubt. In case removal of the brake drum is not easy, make sure that the parking brake has been fully disengaged and loosen the parking brake cable nut as the need be, to withdraw the brake shoes. Prior to the attaching brake drum, examine it, cracks, score marks, deep scratches and hard spots, and in case any problems are detected, go to an automotive machine shop and have the brake drum resurfaced, as this is what professional would advise every time they undertake a brake job to avoid out of round drums. When the drums are too much worn then new ones will be needed. Either run off the glaze with emery cloth or sandpaper at least. Test the brake drum Check the work of the automatic adjuster then have an assistant depress the brake pedal and test the work of the brake drum before fitting the brake drum to the axle flange. Install the wheel and the lug nuts and make sure that you place the new brake shoes so that they will not drag when you release the brake pedal. Reduce the vehicle height, screw the lug nuts to the required torque and do a few forward and back stops under the condition of the parking brake to test satisfactory pedal activity and make sure that brakes are working well before driving.

Related Mazda Parts

Browse by Model

2 Brake Shoe Set 323 Brake Shoe Set 626 Brake Shoe Set 929 Brake Shoe Set B2000 Brake Shoe Set B2200 Brake Shoe Set B2300 Brake Shoe Set B2500 Brake Shoe Set B2600 Brake Shoe Set B3000 Brake Shoe Set B4000 Brake Shoe Set CX-7 Brake Shoe Set CX-9 Brake Shoe Set MPV Brake Shoe Set MX-3 Brake Shoe Set MX-6 Brake Shoe Set Millenia Brake Shoe Set Protege Brake Shoe Set Protege5 Brake Shoe Set Tribute Brake Shoe Set