×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

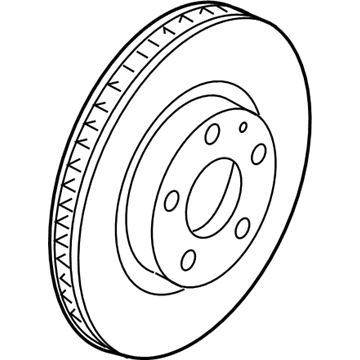

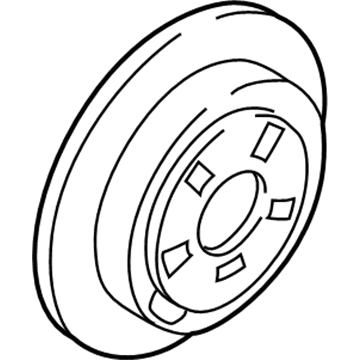

Genuine Mazda Brake Disc

Disc Rotor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

101 Brake Discs found

Mazda Rotor Part Number: DGJ6-26-251

$64.60 MSRP: $86.15You Save: $21.55 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Plate, Disc; Rotor

Mazda Rotor Part Number: VA40-26-251

$69.96 MSRP: $93.30You Save: $23.34 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Plate, Disc; Rotor

Mazda Disc Part Number: EF91-26-251A

$70.19 MSRP: $93.60You Save: $23.41 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Plate, Disc; Disc

- Replaces: EFTT-26-251, EF91-26-251

Mazda Rotor Part Number: B45A-33-251A

$88.65 MSRP: $118.22You Save: $29.57 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Plate, Disc

Mazda Rotor Part Number: B45G-26-251B

$88.65 MSRP: $118.22You Save: $29.57 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Plate, Disc; Rotor

- Replaces: B45G-26-251A

Mazda Rotor Part Number: BJ0Y-33-25X

$77.20 MSRP: $102.95You Save: $25.75 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Plate, Disc

Mazda Rotor Part Number: BJ1Y-33-25X

$77.20 MSRP: $102.95You Save: $25.75 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Plate, Disc

Mazda Rotor Part Number: DF71-33-251A

$81.70 MSRP: $108.95You Save: $27.25 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Plate, Disc

- Replaces: DF71-33-251

Mazda Rotor Part Number: EF9Y-33-25X

$77.20 MSRP: $102.95You Save: $25.75 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Plate (I Model/Pf#05-08)

- Replaces: E100-33-25XA, E100-33-25X, EC02-33-25X-MV, EC02-33-25X

Mazda Rotor Part Number: GHT2-26-251

$88.65 MSRP: $118.22You Save: $29.57 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Plate, Disc

Mazda Rotor Part Number: GK2Y-33-25XF

$77.20 MSRP: $102.95You Save: $25.75 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Plate, Disc

Mazda Rotor Part Number: GTYF-26-251C

$81.70 MSRP: $108.95You Save: $27.25 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Rotor, Brake

Mazda Rotor Part Number: K011-26-251C

$88.65 MSRP: $118.22You Save: $29.57 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Plate, Disc; Rotor

- Replaces: K011-26-251A, K011-26-251B

Mazda Rotor Part Number: N06Y-33-25X

$81.70 MSRP: $108.95You Save: $27.25 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Plate, Disc

- Replaces: N0YY-33-25X

Mazda Rotor Part Number: N251-26-251

$81.70 MSRP: $108.95You Save: $27.25 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Plate, Disc

Mazda Rotor Part Number: N251-33-251

$81.70 MSRP: $108.95You Save: $27.25 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Plate, Disc

Mazda Rotor Part Number: NA01-26-251D

$81.70 MSRP: $108.95You Save: $27.25 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Disc Plate

- Replaces: NA01-26-251C

Mazda Rotor Part Number: TK78-26-251A

$88.65 MSRP: $118.22You Save: $29.57 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Plate, Disc

- Replaces: TK78-26-251

Mazda Rotor Part Number: TK78-33-251B

$88.65 MSRP: $118.22You Save: $29.57 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Plate, Disc; Rotor

- Replaces: TK78-33-251, TK78-33-251A

Mazda Rotor Part Number: TY32-26-251A

$77.20 MSRP: $102.95You Save: $25.75 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Plate, Disc; Rotor

| Page 1 of 6 |Next >

1-20 of 101 Results

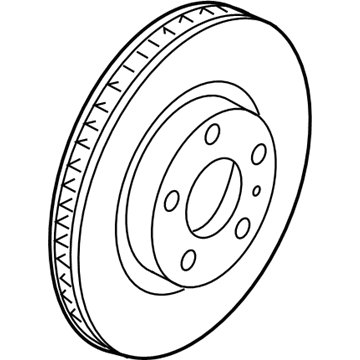

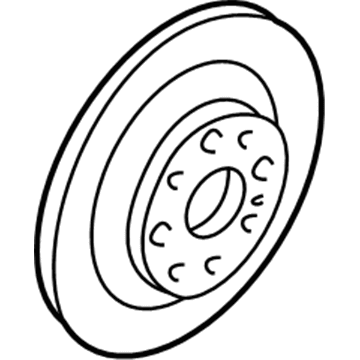

Mazda Brake Disc

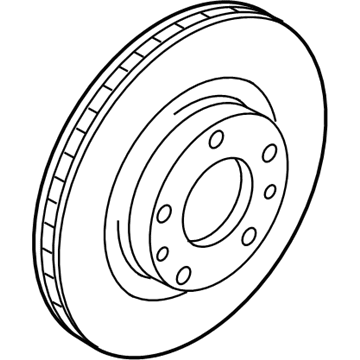

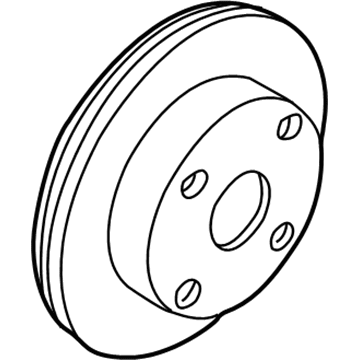

The brake disc is a key part of your vehicle's braking system. When you need to stop, it plays an important role in conjunction with the brake pads to create torque for deceleration. With time, Mazda brake disc replacement will become necessary because of the tough mechanical and thermal strains that it goes through, as well as exposure to water and road debris. If your brake disc falls below acceptable thresholds upon routine inspection, there is no way but to replace it. Luckily enough, this task can be done by you alone, keeping your car safe and responsive on the roads.

Whenever you need replacements, opt for genuine Mazda Brake Discs. Because they meet the manufacturer's criteria, it guarantees that replacements fit perfectly. Thus, these make better choices for people who care about driving. Why should you shop at MazdaPartsNow.com? We sell genuine Mazda Brake Discs. In our online catalog, there is a wide range of different parts. These are delivered directly from authorized Mazda dealers only so that customers can be sure of their security throughout any transaction while using our website. Furthermore, you can also quickly search for OEM parts you want because of our user-friendly site navigation. Choose us for a genuine Mazda Brake Disc that keeps your car running like new.

Mazda Brake Disc Parts and Q&A

- Q: Do brake discs contain asbestos, and how should one safely clean brake surfaces on Mazda B2200?A:The brakes pads can be composed of asbestos which is a known cause of cancer. Cleaning of brake surfaces should be done without using compressed air and it should also avoid inhaling any dust on the surface. A commercially available brake cleaning fluid should be used when cleaning.

- Q: How to remove, install, and adjust front Brake Disc on Mazda GLC?A:To remove and install front wheel bearing and to adjust the preload on rears when the car is on the rear wheel drive, the procedure involves removal of the caliper assembly, which can be left with the hydraulic line and attached to the underbody in case the complete removal is not required. Then remove the disc run-out, verify the run-out, then remove the cotter pin, nut lock, adjusting nut and washer of the spindle, thrust washer and outer bearing of the hub. Removing the brake disc/wheel hub assembly off the spindle, matchmarking the disc and hub and unbolstering the disc off the hub to ensure that the disc does not get driven off the hub. The bearings are installed in the opposite direction modifying the bearing preload. In front wheel drive cars, loosen the lug nuts, lift the front end of the car and place it on jackstands and then remove the tire and the wheel. Test disc run-out, lift the staked tab on the hub center nut, and remove the nut and secure the rotor by pressing the brake. Take off the brake caliper, prop it to the side, and dislodge the rotor off the hub. Install the rotor onto the hub, then the caliper assembly then install a new axle locknut to a specified torque then staked. On subsequent models, lift up the vehicle, stabilize, and check the play in the rotor and the wheel bearing, making sure that there is no evident play. Take the wheel and tire off, detach the brake line and the strut and suspend the caliper out of the way without removing the hydraulic line. Unscrew the rotor out of the hub, and screw it back into the hub then screw the caliper assembly in and ensure that the correct torque requirements are followed on the caliper bolts and driveshaft locknut. In different models, lift up the vehicle, hold it safe, check the disc brake rotor, and in case of need, take out the wheel bearing. Once the roughness or strange sound is checked, loosen the brake caliper without detaching the hydraulic line, and then take the rotor off of the hub and replace it on the hub together with the brake caliper making sure that the bolts and locknut have the right torque. In the case of the RX-7 models, it is necessary to remove brake caliper, anti-rattle spring, brakes pads and shims, then the caliper bracket, grease cap, split pin, nut lock, adjusting nut, washer, and outer wheel bearing, and finally, the rotor disc. Installation This is carried out by packing the outer bearing with grease and reassembling the brake caliper and front wheels. The inspection involves checking the lateral run-out of the disc using a dial indicator in place, that all wheel bearings are correctly adjusted and removing or resurfacing the disc in case the run-out is out of specification, and checking whether there are any scores or pits on the disc surface.

Related Mazda Parts

Browse by Model

2 Brake Disc 3 Brake Disc 323 Brake Disc 5 Brake Disc 6 Brake Disc 626 Brake Disc 929 Brake Disc B2000 Brake Disc B2200 Brake Disc B2300 Brake Disc B2600 Brake Disc B3000 Brake Disc B4000 Brake Disc CX-3 Brake Disc CX-30 Brake Disc CX-5 Brake Disc CX-50 Brake Disc CX-7 Brake Disc CX-9 Brake Disc GLC Brake Disc MPV Brake Disc MX-3 Brake Disc MX-30 EV Brake Disc MX-5 Miata Brake Disc MX-6 Brake Disc Miata Brake Disc Millenia Brake Disc Navajo Brake Disc Protege Brake Disc Protege5 Brake Disc RX-7 Brake Disc RX-8 Brake Disc Tribute Brake Disc