×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mazda Parts

My Garage

My Account

Cart

Genuine Mazda Camshaft

Cam- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

96 Camshafts found

Mazda Camshaft Part Number: L3E3-12-420

$683.59 MSRP: $934.05You Save: $250.46 (27%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Intake Camshaft

Mazda Camshaft Part Number: AJ95-12-440

$100.16 MSRP: $133.58You Save: $33.42 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Camshaft(Right), Exhaust; Exhaust Camshaft

Mazda Camshaft Part Number: PX13-12-420

$107.46 MSRP: $143.31You Save: $35.85 (26%)Ships in 1-2 Business DaysProduct Specifications- Replaced by: PX13-12-420A

Mazda Camshaft Part Number: PX13-12-440

$113.95 MSRP: $151.96You Save: $38.01 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Camshaft, Exhaust; Camshaft

Mazda Camshaft Part Number: PXNS-12-440

$111.73 MSRP: $149.00You Save: $37.27 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Camshaft, Exhaust

- Replaced by: PXNS-12-440A

Mazda Camshaft Part Number: AJ95-12-430

$119.68 MSRP: $159.60You Save: $39.92 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Camshaft(Left), Intake; Intake Camshaft

Mazda Camshaft Part Number: PEP8-12-440

$118.99 MSRP: $158.69You Save: $39.70 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Camshaft, Exhaust; Camshaft

- Replaced by: PEP8-12-440A

- Replaces: PE27-12-440

Mazda Camshaft Part Number: AJ03-12-450A

$125.60 MSRP: $167.50You Save: $41.90 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Camshaft Left, Exhaust; Camshaft

- Replaces: AJ03-12-450

Mazda Camshaft Part Number: AJTM-12-420

$127.73 MSRP: $170.33You Save: $42.60 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Camshaft Right, Intake; Camshaft

- Replaces: AJ03-12-420A, AJ03-12-420

Mazda Camshaft Part Number: LF01-12-421A

$132.23 MSRP: $176.34You Save: $44.11 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Camshaft, Intake

Mazda Camshaft Part Number: CA01-12-420

$159.91 MSRP: $213.26You Save: $53.35 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Camshaft(Right), Intake

Mazda Camshaft Part Number: CA01-12-440

$148.18 MSRP: $197.61You Save: $49.43 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Camshaft(Right), Exhaust

Mazda Camshaft Part Number: CA01-12-450

$159.91 MSRP: $213.26You Save: $53.35 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Camshaft(Left), Exhaust

Mazda Intake Camshaft Part Number: AJTT-12-420A

$164.60 MSRP: $219.51You Save: $54.91 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Camshaft Right, Intake

- Replaces: AJ57-12-420B, AJ57-12-420A, AJTT-12-420, AJ57-12-420

Mazda Camshaft Part Number: PX17-12-420

$184.36 MSRP: $245.87You Save: $61.51 (26%)Ships in 1-2 Business DaysProduct Specifications- Replaced by: PX17-12-420A

Mazda Camshaft Part Number: PE01-12-420

$195.64 MSRP: $260.91You Save: $65.27 (26%)Ships in 1-2 Business DaysMazda Camshaft Part Number: PEES-12-440

$181.39 MSRP: $241.89You Save: $60.50 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Camshaft, Exhaust

Mazda Camshaft Part Number: PEJE-12-440

$189.28 MSRP: $252.42You Save: $63.14 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Camshaft, Exhaust

Mazda Exhaust Camshaft Part Number: AJ57-12-450B

Product Specifications- Other Name: Camshaft Left, Exhaust

Mazda Camshaft Part Number: CA01-12-430

Product Specifications- Other Name: Camshaft(Left), Intake

| Page 1 of 5 |Next >

1-20 of 96 Results

Mazda Camshaft

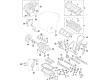

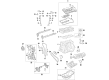

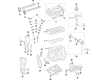

The camshaft, a pivotal component of the internal combustion engine, is situated within. It is shaped like a cylinder and aligns with the engine's cylinders, which makes it possible for the valves to open and close. This alignment has to be there if an engine is to work properly. The timing belt links the crankshaft with the camshaft. The purpose of this is that they coordinate in such a way that when piston strokes occur, valves open and close. The Mazda camshaft and timing belt have to be checked regularly for better performance. A camshaft or timing belt failure means the danger of system faulting and probable damage to your car's engine as well. Modern vehicles have dual overhead camshafts: one regulates intake valves while another controls exhaust ones.

Whenever you need replacements, opt for genuine Mazda Camshafts. Because they meet the manufacturer's criteria, it guarantees that replacements fit perfectly. Thus, these make better choices for people who care about driving. Why should you shop at MazdaPartsNow.com? We sell genuine Mazda Camshafts. In our online catalog, there is a wide range of different parts. These are delivered directly from authorized Mazda dealers only so that customers can be sure of their security throughout any transaction while using our website. Furthermore, you can also quickly search for OEM parts you want because of our user-friendly site navigation. Choose us for a genuine Mazda Camshaft that keeps your car running like new.

Mazda Camshaft Parts and Q&A

- Q: How should camshafts and valve lifters be removed and reinstalled during a procedure on Mazda 3?A:At any time that the cams are to be pulled to perform a procedure, it is recommended to verify the valve clearance prior to breaking them down so that any new lifters necessary are available to be ordered out of a dealership. Start by taking out the timing chain, marking the location of the no.1 cylinder cam lobes and locations of the slots in the ends of the camshafts to line up with the slot during reassembly. Then, taken-out the camshaft sprockets and label the camshaft phaser/sprocket on the intake camshaft to be installed in the correct position. The Variable Valve Timing models have various camshaft sprocket bolts that are required to be aware of, with appropriate washers being used as necessary. The camshaft carrying caps are numbered and should be returned to their original place, the side with the number face upwards. Relax the camshaft bearing cap bolts gradually, then pull the caps off taking note of their markings, and take out the camshafts. Store lifters in small containers and do not mix them. Look at the camshafts and lifters, and then feel their wear and roundness, and take the outside diameter of all lifters and see whether they have any appreciable differences. Inspect the camshaft lobes visually and inspect the bearing journals visually. Measure the diameter of each journal and measure the degree of running clearance of the bearing journal with Plastigage. In case one of the bearings becomes worn out of service, it may be required to replace a camshaft. In order to measure camshaft endplay, check with a dial indicator with the bearing surfaces cleaned. To install, make sure that the crankshaft is at TDC, lubricate the lifter bores and camshaft bearing surfaces, and then place the lifters and camshafts in place using care to ensure that they fit in their original position. Clean all mating surfaces and oil the camshaft journals and lobes and then put the bearing caps into their normal positions. Install the sprockers to the camshafts, in sequence to the required setting of camshaft bearing cap bolts, and when installing the camshaft bearing cap bolts, it is important to install the various washers as necessary. Install the valve cover after finishing the reassembly process which consists of replacing the timing chain and adjusting the valve timing, and the valve clearance.

- Q: How to remove and install the valve cover and camshaft while ensuring proper timing and inspection on Mazda MPV?A:To change the valve cover, the first step is to remove the distributor and position the engine at TDC with cylinder number one then remove the rocker arm assembly with the camshaft bearing caps numbered, if not numbered then number it. To avoid the tensioner collapsing once the sprocket has been removed, fit a special retaining tool between the timing chain by the tensioner so that the cord or wire of the tool does not lose its way in the timing chain cover. The next step is to loosen the camshaft sprocket bolt and the distributor drive gear without allowing the camshaft to move using a screwdriver. Unscrew the timing chain and camshaft sprocker and remove the camshaft and clean it. To check, investigate endplay of the camshaft by clamping the camshaft with caps and measuring the movement with a dial indicator and comparing them with the specification. Measure camshaft run out with V-blocks and dial indicator and replace the camshaft where the run out is out of specification. Inspect the wear and wear cap of the camshaft bearings and alternate these, and check the height of the cam lobes by a micrometer with reference to wear or damage. Check the wear of the rocker arms and the difficulties of lubrication and be sure to lubricate the new parts before fitting them in. Installation To install, clean all the parts, lubricate the journals and the camshafts bearing surfaces and lower the camshaft carefully with the dowel pin facing up. Install the rocker arm and camshaft sprocker with timing chain making sure that the timing is correct. Turn the crankshaft by hand until the timing marks appear coincidental following two revolutions and in case of resistance examine the valve timing. Last but not the least: Do the reversal of steps of installation.

Related Mazda Parts

Browse by Model

2 Camshaft 3 Camshaft 323 Camshaft 5 Camshaft 6 Camshaft 626 Camshaft B2000 Camshaft B2200 Camshaft B2300 Camshaft B2600 Camshaft B4000 Camshaft CX-3 Camshaft CX-30 Camshaft CX-5 Camshaft CX-7 Camshaft CX-9 Camshaft MPV Camshaft MX-3 Camshaft MX-5 Miata Camshaft MX-6 Camshaft Miata Camshaft Millenia Camshaft Protege Camshaft Protege5 Camshaft Tribute Camshaft